Open-cut type non-column large-span arched subway station structure as well as design and construction method

A technology for subway stations and open-cutting, applied in infrastructure engineering, underwater structures, artificial islands, etc., to achieve the effects of clear and reasonable force, convenient and feasible construction, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

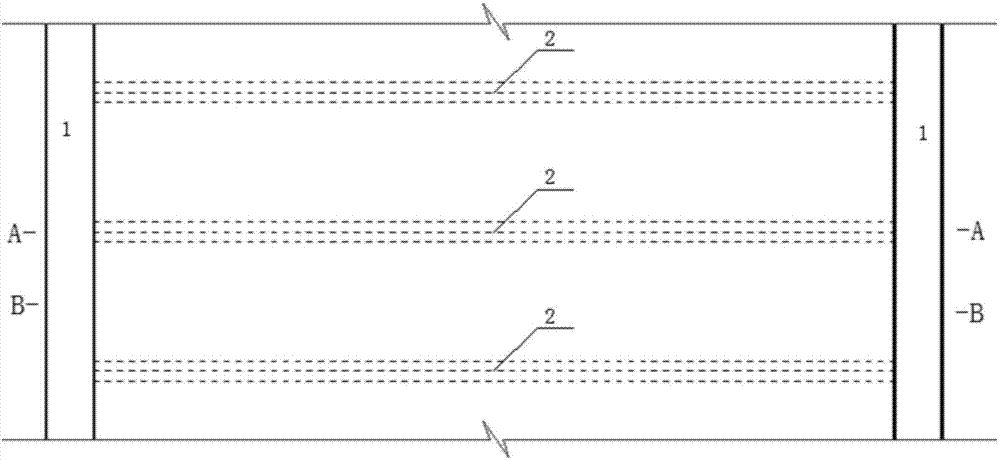

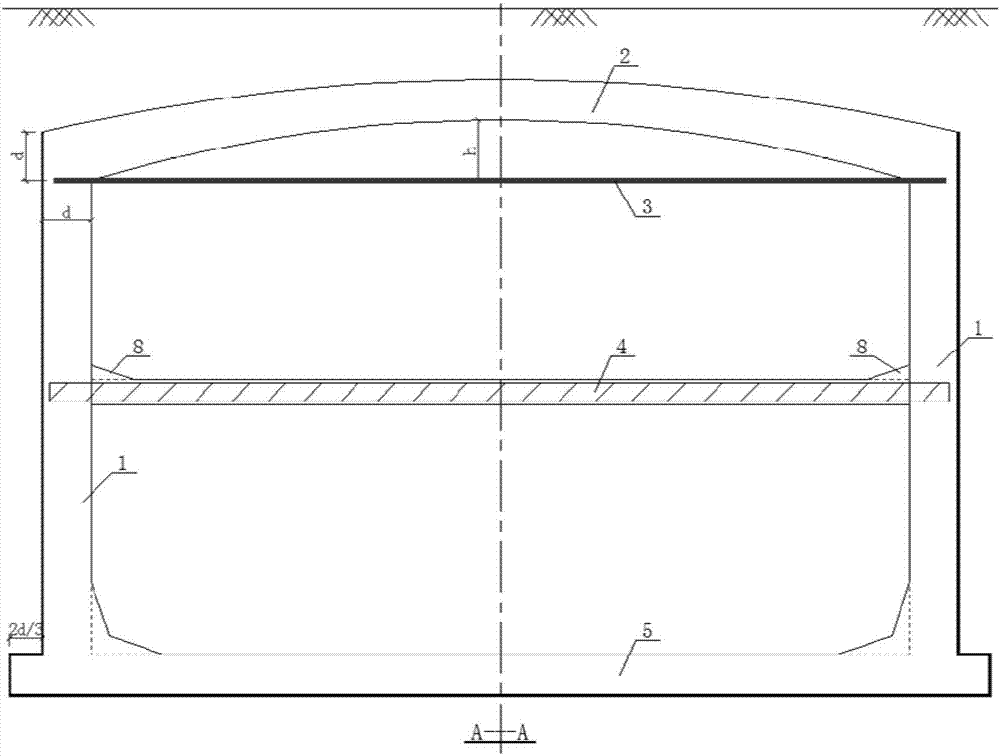

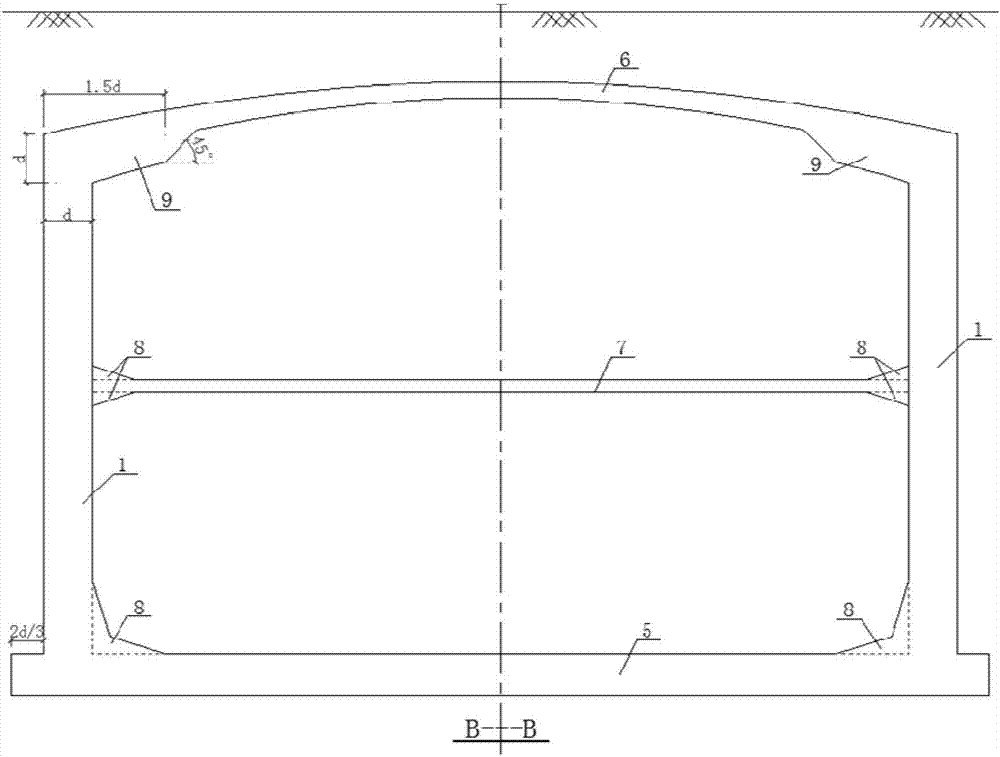

[0037] refer to figure 1 , figure 2 and image 3 , the open-cut column-free large-span arched subway station structure described in this embodiment, the structure includes: a bottom plate 5, a side wall 1, a middle plate 7, a middle beam 4, an arch plate 6, an arch beam 2 and prestressed cables 3;

[0038] Two side walls 1 parallel to each other are relatively arranged on the base plate 5, and a passage is formed between the two side walls 1 oppositely arranged as a subway station passage; along the direction of the passage, a plurality of arch beams 2 arranged evenly, each arch The beam spans the tops of the two side walls 1, and an arch plate 6 is arranged between two adjacent arch beams 2, and each arch plate spans the top ends of the two side walls 1 and is located on the same arch beam. 2 The arch plates 6 on both sides are connected to each other; prestressed cables 3 are set between the two arch feet of the same arch beam 2; each arch plate 6 is connected to each si...

Embodiment

[0056] refer to Figure 4 , the present embodiment is used for the design and construction method of the open-cut column-free large-span arched subway station structure as described in embodiment 1, and the method includes:

[0057] S1, under a certain excavation condition of the foundation pit, two rows of slope protection piles 10 are designed and constructed to obtain the station passage;

[0058] First construct the slope protection piles 10, and then excavate the soil within the scope of the two rows of slope protection piles 10. During the excavation of the soil, use several anchor cables or horizontal inner supports to support the two rows of slope protection piles 10, and excavate the soil Side support slope protection pile 10, until the excavation reaches the design bottom elevation. The slope protection pile 10 generally adopts reinforced concrete material.

[0059] S2. At the bottom of the passageway of the station, according to the pre-design requirements, constr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com