Device and method for clearing sand and water production in hydrate wells by utilizing bottom gas production

A technology of hydrate and hydrate inhibitor, which is applied in the direction of wellbore/well valve device, earthwork drilling and production, wellbore/well parts, etc. It can solve the problem of not being able to completely block fine sand particles, and achieve safe and efficient development, improve The effect of natural gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

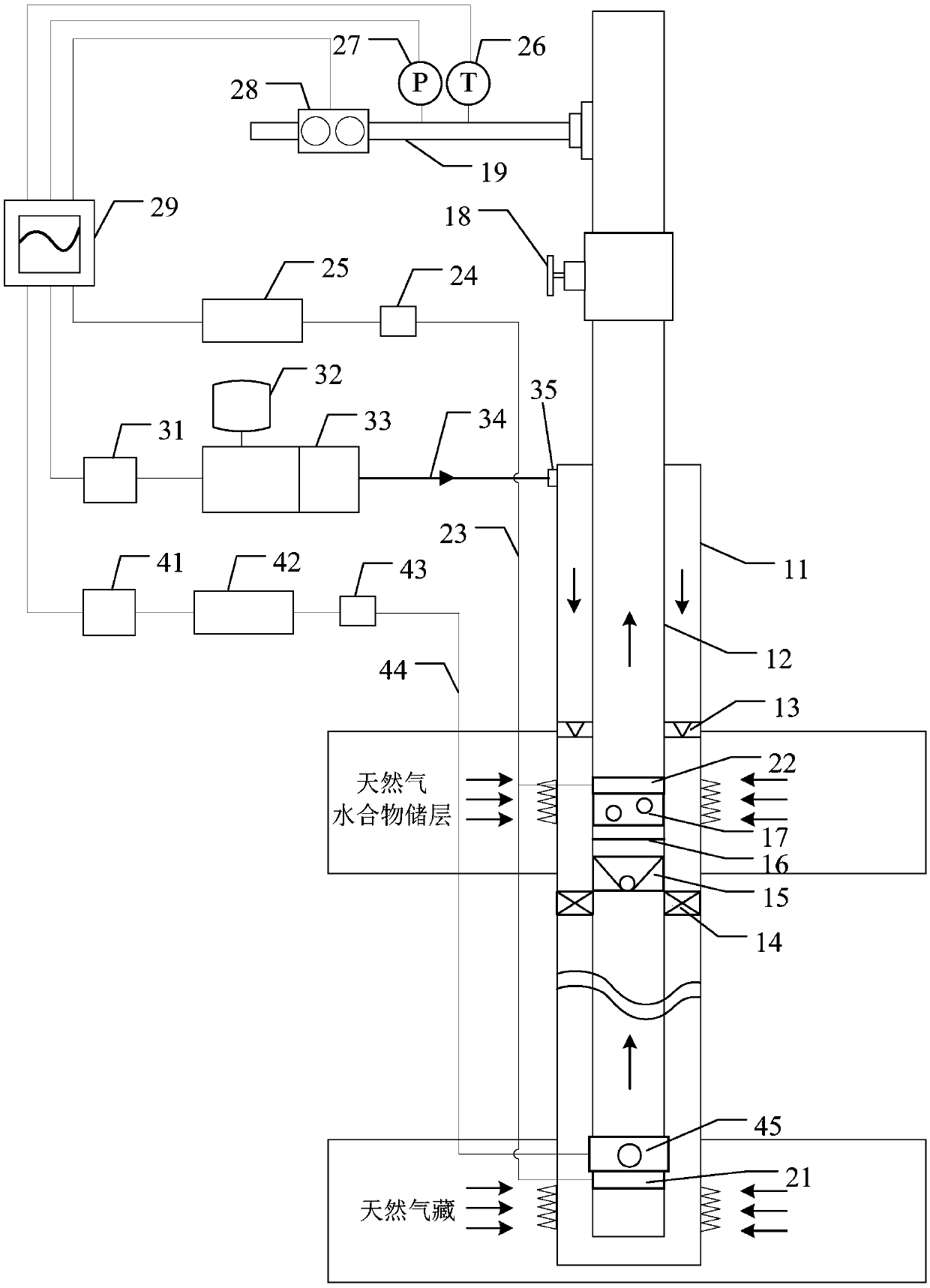

[0016] Such as figure 1 As shown, in the process of natural gas hydrate production, the string system consists of casing 11 and production string 12, and the casing annulus (the cavity between casing 11 and production string 12) and the production string are both fluid Provide a flow channel; a downward check valve 13 is installed in the upper casing annulus of the natural gas hydrate production position, a packer 14 is installed in the lower casing annulus, and an upward check valve is installed in the lower production string. Flow valve 15; a sand retaining screen 16 and a perforated pipe 17 are installed on the upper end of the upward check valve 15. The function of the sand retaining screen 16 is to prevent the sand entering the production pipe string during the natural gas hydrate exploitation process from sinking into the production pipe string At the bottom, the perforated pipe 17 provides a channel for the fluid to enter the production string from the annulus; the well...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com