Design method and device for lubricating oil system for air blower and auxiliary equipment of compressor

A technology of lubricating oil and compressor, applied in the field of lubricating oil system, to achieve the effect of avoiding duplication of work and preventing data leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

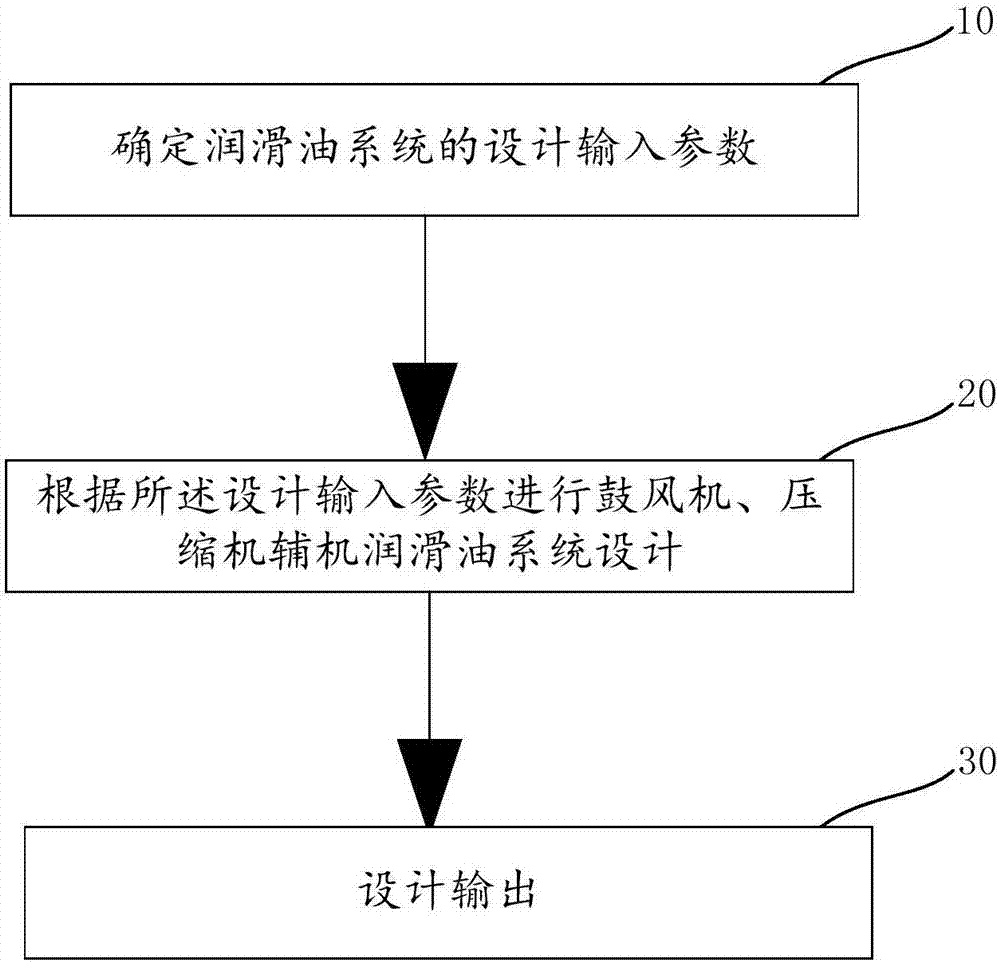

[0022] see figure 1 , the design method for the lubricating oil system of blower and compressor auxiliary machine that the embodiment of the present invention provides, comprises:

[0023] Step 10. Determine the design input parameters of the lubricating oil system; the design input parameters include project information, industry design standards, a list of blower lubrication equipment, lubricating oil properties, lubricating oil flow pressure, lubricating oil supply pressure, accumulator The placement position of the compressor, the idling time of the compressor, the components of the lubricating oil system and the common engineering conditions; the lubricating oil system is used for blowers and compressor auxiliary machines.

[0024] Among them, the project information includes user name, project address, project name, project number, contract number, quotation number, device name, version information, design, proofreading, review: output of purchased parts agreement, instr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com