Subway safety door self-check method

A technology for safety doors and subways, applied in optical device exploration, etc., can solve problems such as undetectable clothing, light and thin hair objects, and endangering the personal safety of passengers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

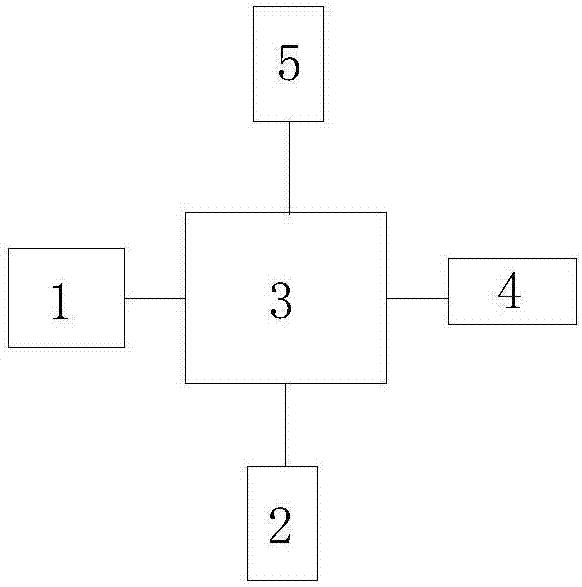

[0020] Embodiment: A kind of subway safety door self-inspection method

[0021] See attached figure 1 , pre-build a self-test platform, the self-test platform includes a laser emission module 1, a laser detection module 2, a laser mirror, a microprocessor 3, a data transmission module 4 and a data reception module 5; the laser emission module 1, Laser detection module 2, data sending module 4, data receiving module 5 are connected with microprocessor 3 respectively, and described laser reflector is installed on the door edge of subway safety door two-leaf door, and described door edge is the subway safety door two-leaf door The opposite edge: the laser emitting module 1 is installed on the upper end of the subway safety door edge, and the laser detection module 2 is installed on the lower end of the subway safety door door edge.

[0022] When in use, when the subway safety door is normally closed, the laser emitted by the laser emitting module 1 can reach the laser detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com