Method for quickly generating two-dimensional random aggregate model of concrete with pebbles and crushed stones

A concrete and aggregate technology, applied in instruments, geometric CAD, calculation, etc., can solve the problems of long, time-consuming from several minutes to dozens of minutes, difficult to achieve parallel processing, high computer heating and noise, etc., and achieves low CPU consumption. , The calculation time is short, and the shape of the aggregate is realistic.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The purpose of this embodiment is to generate a concrete two-dimensional random aggregate model with only pebbles, which belongs to a special case of the method of the present invention.

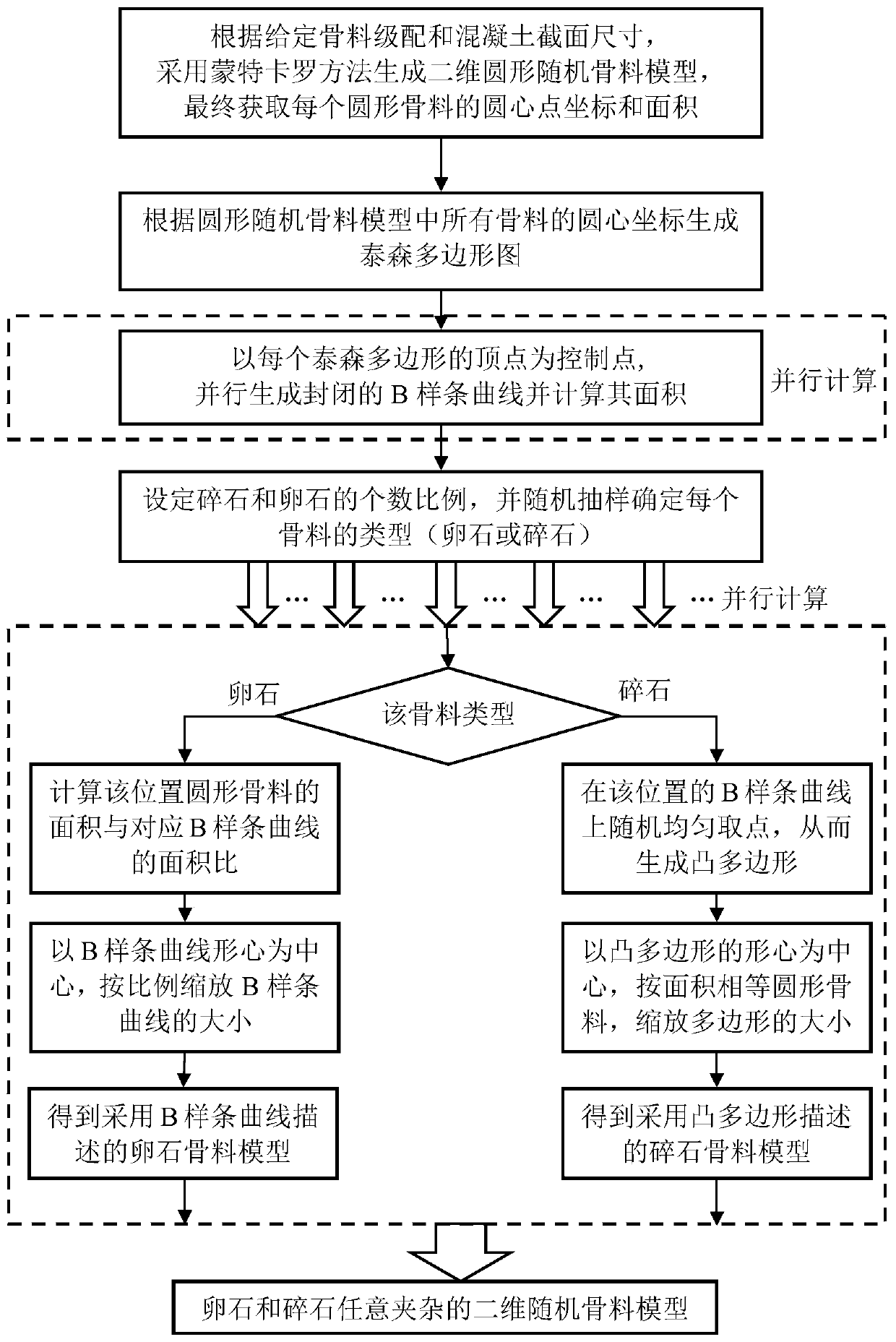

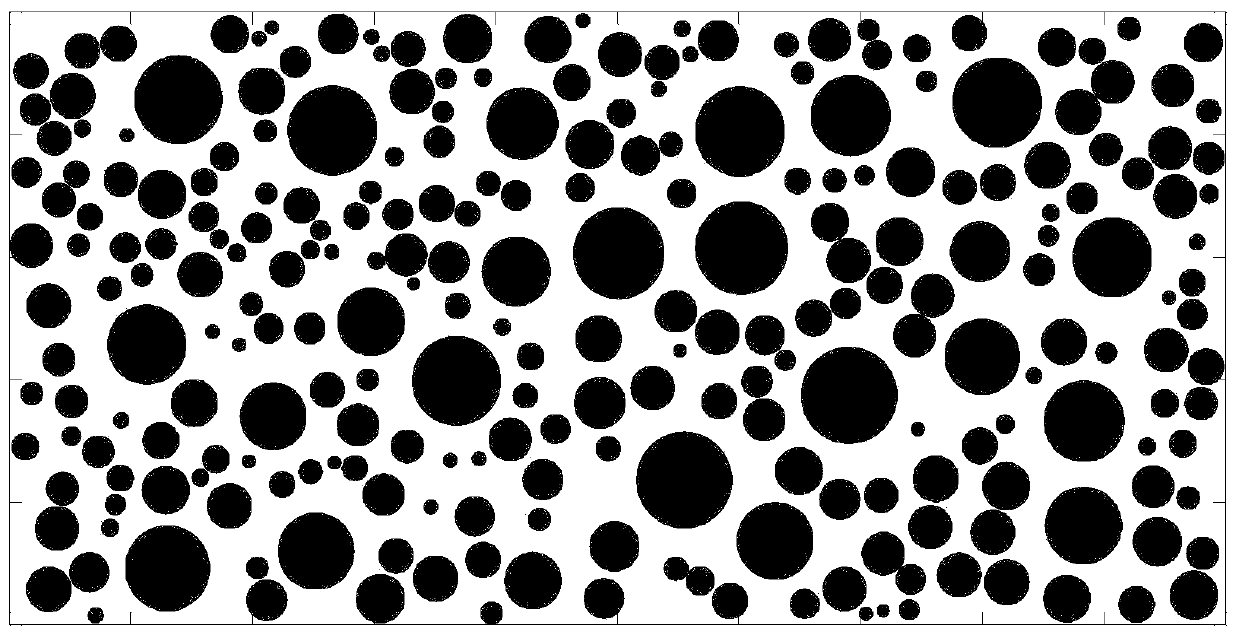

[0036] 1. According to the given aggregate gradation and concrete section size, wherein the aggregate gradation is two-level, the aggregate particle size range is 5~20mm and 20~40mm, and the concrete section size is 500mm×250mm, using Monte Carlo The method generates a two-dimensional circular random aggregate model diagram, and finally obtains the coordinates and area of the center point of each circular aggregate, see figure 2 , the number of round aggregates is 253;

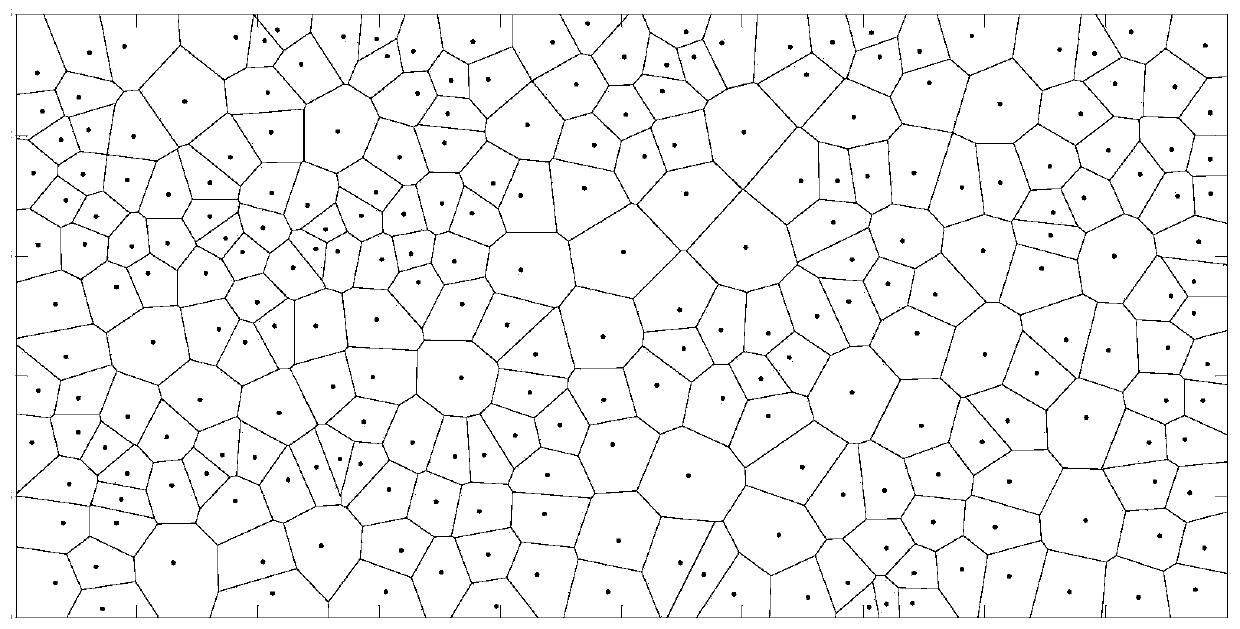

[0037] 2. According to the center coordinates of all aggregates in the circular random aggregate model diagram, generate a Thiessen polygon diagram with boundaries, see image 3 ;

[0038] 3. Using the vertices of each Thiessen polygon as control points, generate a closed B-spline curve in parallel and calculate ...

Embodiment 2

[0042] The purpose of this embodiment is to generate a concrete two-dimensional random aggregate model with only gravel, which belongs to another special case of the method of the present invention.

[0043] 1. According to the given aggregate gradation and concrete section size, wherein the aggregate gradation is two-level, the aggregate particle size range is 5~20mm and 20~40mm, and the concrete section size is 500mm×250mm, using Monte Carlo The method generates a two-dimensional circular random aggregate model diagram, and finally obtains the coordinates and area of the center point of each circular aggregate, see figure 2 , the number of round aggregates is 253;

[0044] 2. According to the center coordinates of all aggregates in the circular random aggregate model diagram, generate a Thiessen polygon diagram with boundaries, see image 3 ;

[0045] 3. Using the vertices of each Thiessen polygon as control points, generate a closed B-spline curve in parallel and calcula...

Embodiment 3

[0049] The purpose of this embodiment is to generate a concrete two-dimensional random aggregate model mixed with pebbles and crushed stones, which belongs to the conventional situation of the method of the present invention.

[0050] 1. According to the given aggregate gradation and concrete section size, wherein the aggregate gradation is two-level, the aggregate particle size range is 5~20mm and 20~40mm, and the concrete section size is 500mm×250mm, using Monte Carlo The method generates a two-dimensional circular random aggregate model diagram, and finally obtains the coordinates and area of the center point of each circular aggregate, see figure 2 , the number of round aggregates is 253;

[0051] 2. According to the center coordinates of all aggregates in the circular random aggregate model diagram, generate a Thiessen polygon diagram with boundaries, see image 3 ;

[0052] 3. Using the vertices of each Thiessen polygon as control points, generate a closed B-spline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com