A kind of pvc pipe threading device and method

A PVC pipe and threading device technology, applied in electromechanical devices, cable installation devices, cable installation, etc., can solve problems such as low efficiency, stuck pipes, time-consuming and labor-intensive problems, and achieve the effect of improving the degree of automation and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

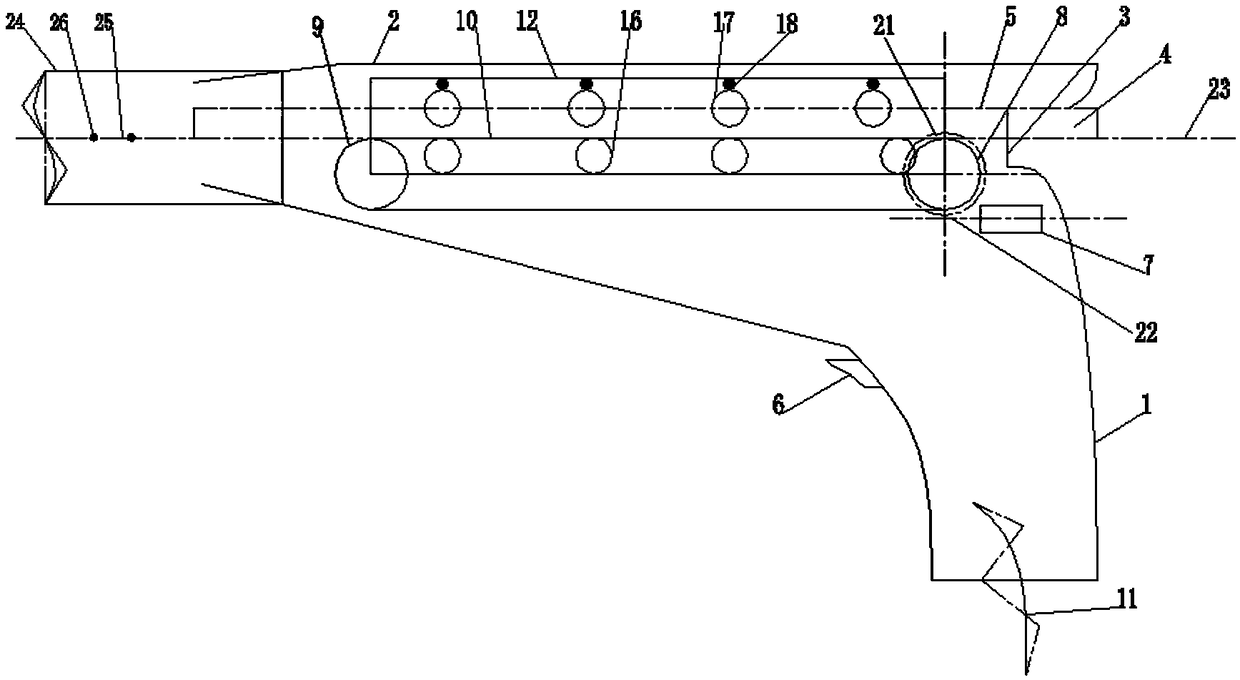

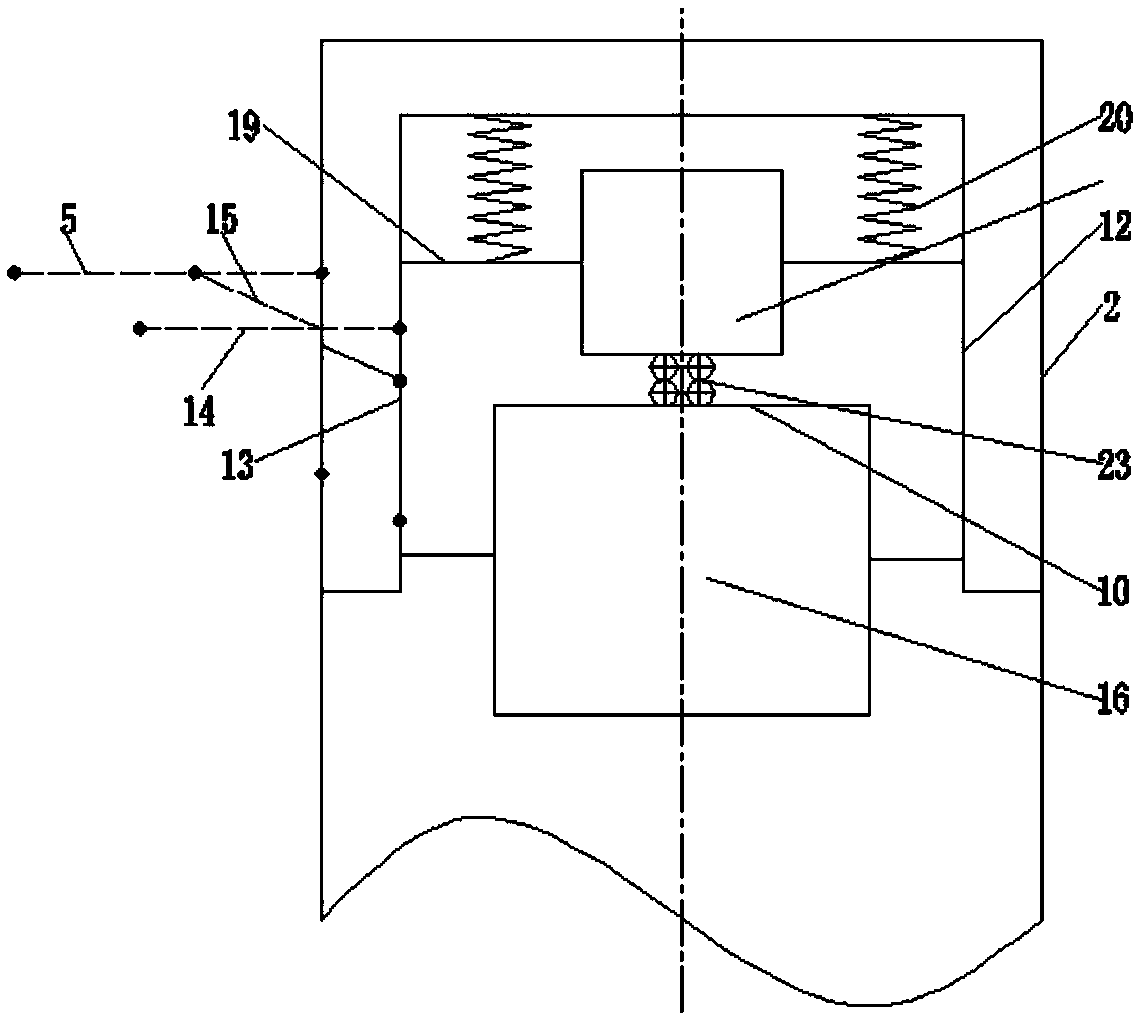

[0017] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018] Such as figure 1 As shown, a PVC pipe threading device includes a housing, a driving device and a clamping and guiding device. The housing includes a hand-held part 1 and a working part 2 connected through each other. In the cavity, the working part is a rectangular box structure with front and rear openings, the rear end is provided with a rear cover 3 and is hingedly connected with the housing, and the outer end face is axially opened with a first line transfer port 4, which passes through the first baffle 5 closed, the first baffle is hingedly connected to the outer end surface of the working part.

[0019] The driving device includes a control switch 6, a motor 7, a transmission mechanism and a belt conveyor assembly. The belt conveyor assembly includes a driving pulley 8, a driven pulley ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com