Bidirectional composite extrusion die and extrusion forming method for magnesium alloy plate and strip

A magnesium alloy plate and composite extrusion technology, which is applied to metal extrusion dies and other directions to achieve the effects of low cost, improved secondary forming and subsequent rolling formability, and improved base surface texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take the shape of the magnesium alloy billet as a cylinder (diameter 500mm, length 1000mm) as an example.

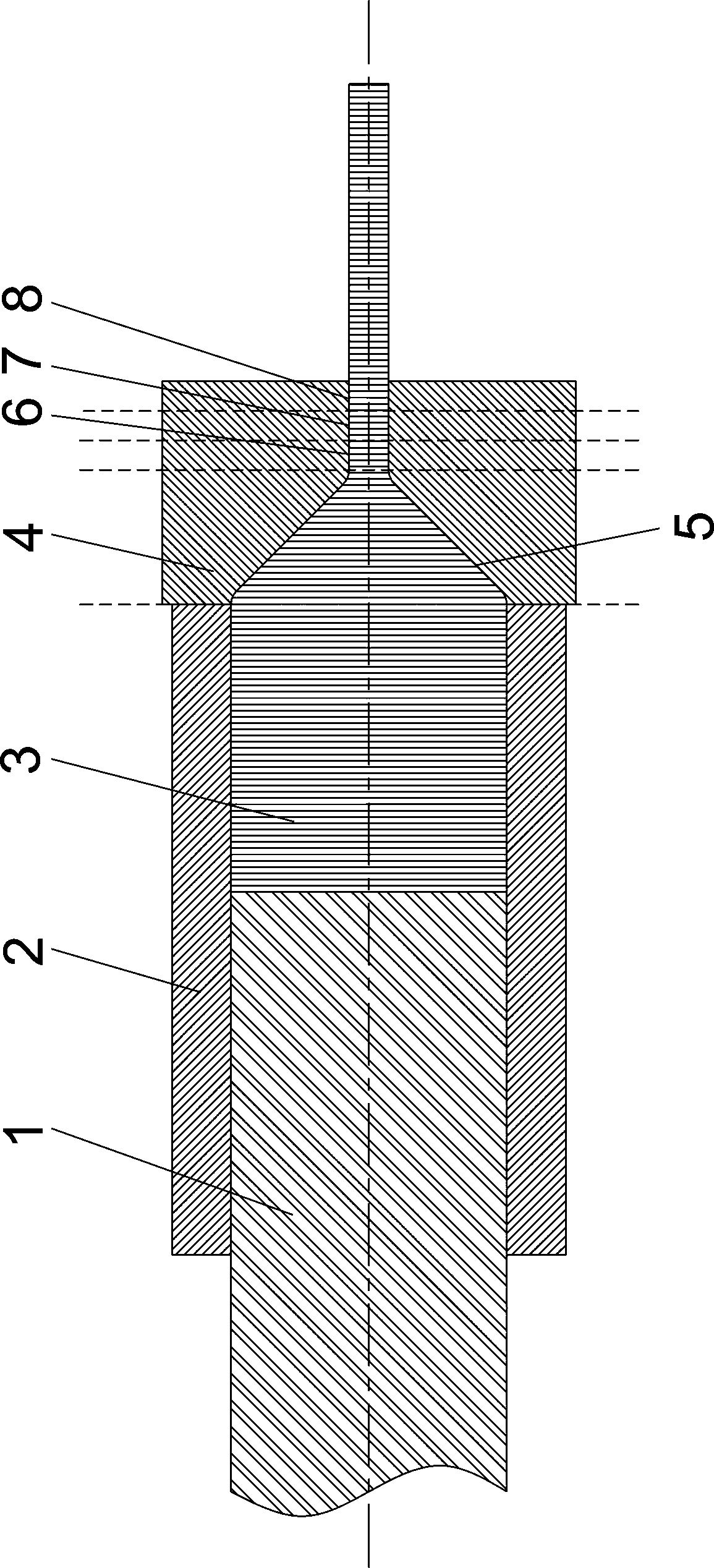

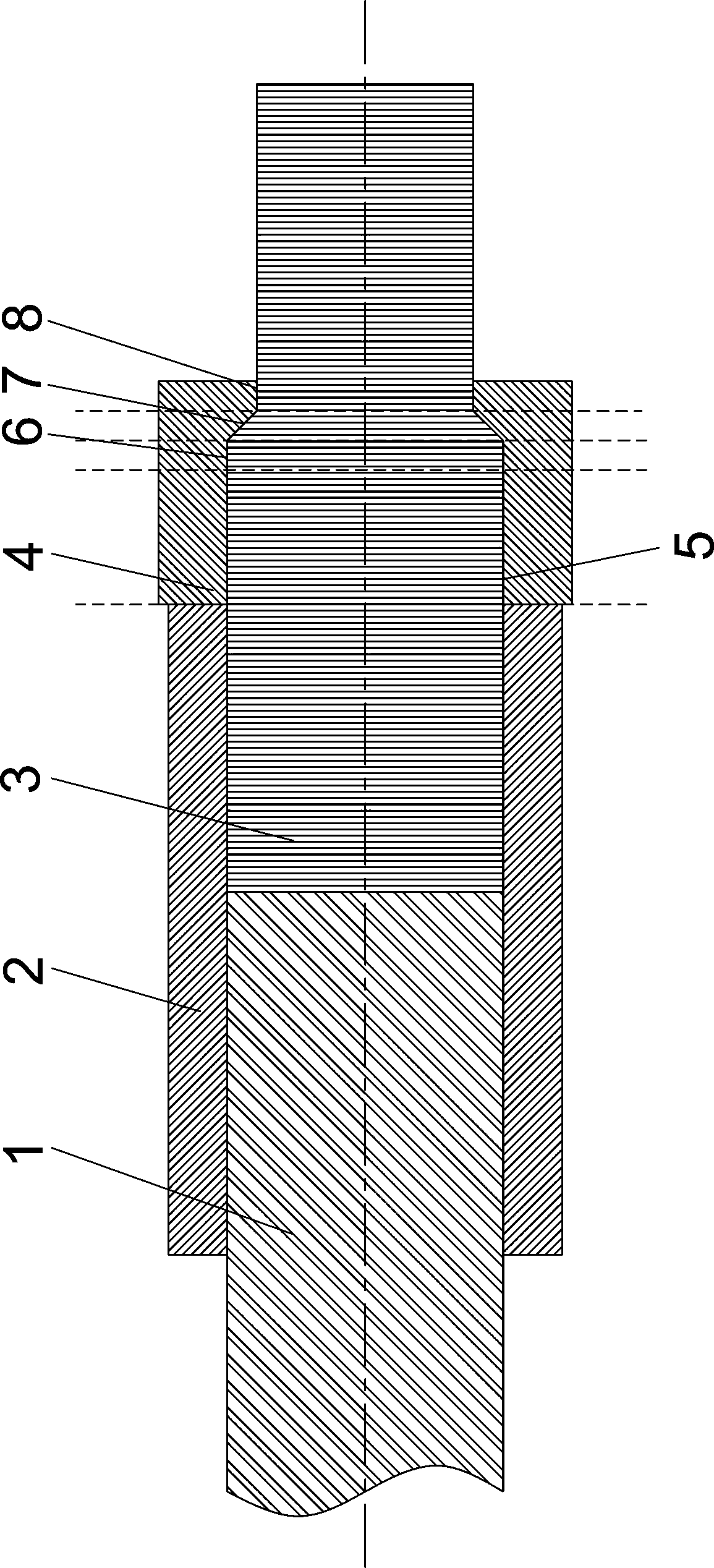

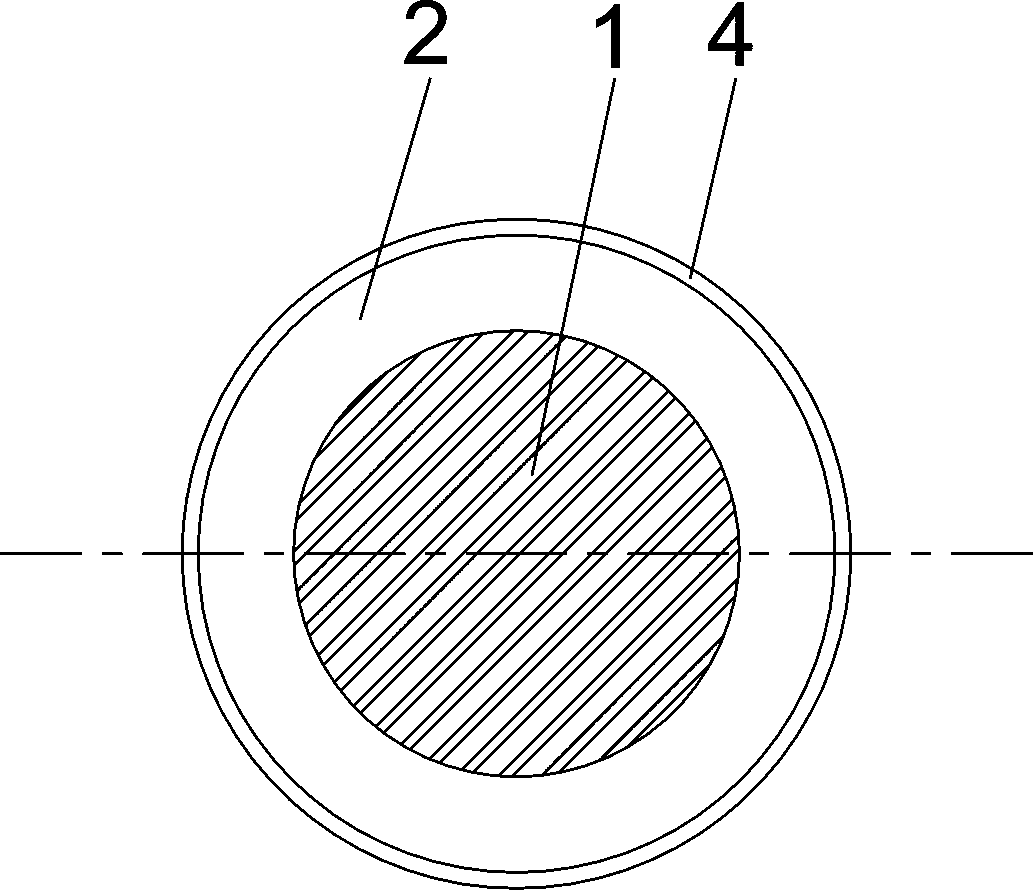

[0031] Such as Figure 1~3 As shown, a two-way compound extrusion die for magnesium alloy plate and strip: includes a cylindrical mold body 4, the left end of the mold body 4 is fixedly connected with a cylindrical extrusion cylinder 2, and the inside of the mold body 4 is along its axis from the left end to the right end. The front extruding channel 5, the transition channel 6, the side extruding channel 7, and the outlet channel 8 are sequentially provided with butt joint communication. The cross-sections of the parts on both sides have the same shape and equal area; the cross-sections of the front extrusion channel 5 and the side extrusion channel 7 gradually become smaller from left to right, and the extrusion cavity, transition channel 6 and outlet of the extrusion cylinder 2 The cross-sections of the channel 8 are equal from left to right; the cross-section...

Embodiment 2

[0039] The difference from Example 1 is that the magnesium alloy billet 3 is in the shape of a slab, the mold body 4, the extrusion cylinder 2, the extrusion cavity of the extrusion cylinder 2, and the pressure rod 1 of the hydraulic press are all in the shape of a slab. The shape of the left end of the extrusion channel 5 also changes correspondingly with the shape of the magnesium alloy billet. The structure of the two-way composite extrusion die in this example is as follows figure 1 , 2 , 4 shown.

Embodiment 3

[0041]The difference from Example 1 is that the shape of the magnesium alloy billet 3 is a cuboid, the shape of the mold body 4, the extrusion cylinder 2, the extrusion cavity of the extrusion cylinder 2, and the pressure rod 1 of the hydraulic press are all cuboid, and the front extrusion The shape of the left end of channel 5 also changes accordingly with the shape of the magnesium alloy billet. The structure of the two-way composite extrusion die in this example is as follows figure 1 , 2 , 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com