Telescopic movable type formwork driving system, formwork system and construction method of formwork system

A driving system and mobile technology, applied in the direction of waterway system, sewer system, water supply device, etc., can solve the problems of increased labor, mechanical equipment shifts, low formwork installation efficiency, increased formwork material loss, etc., to improve formwork Installation efficiency, improve installation efficiency, reduce labor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

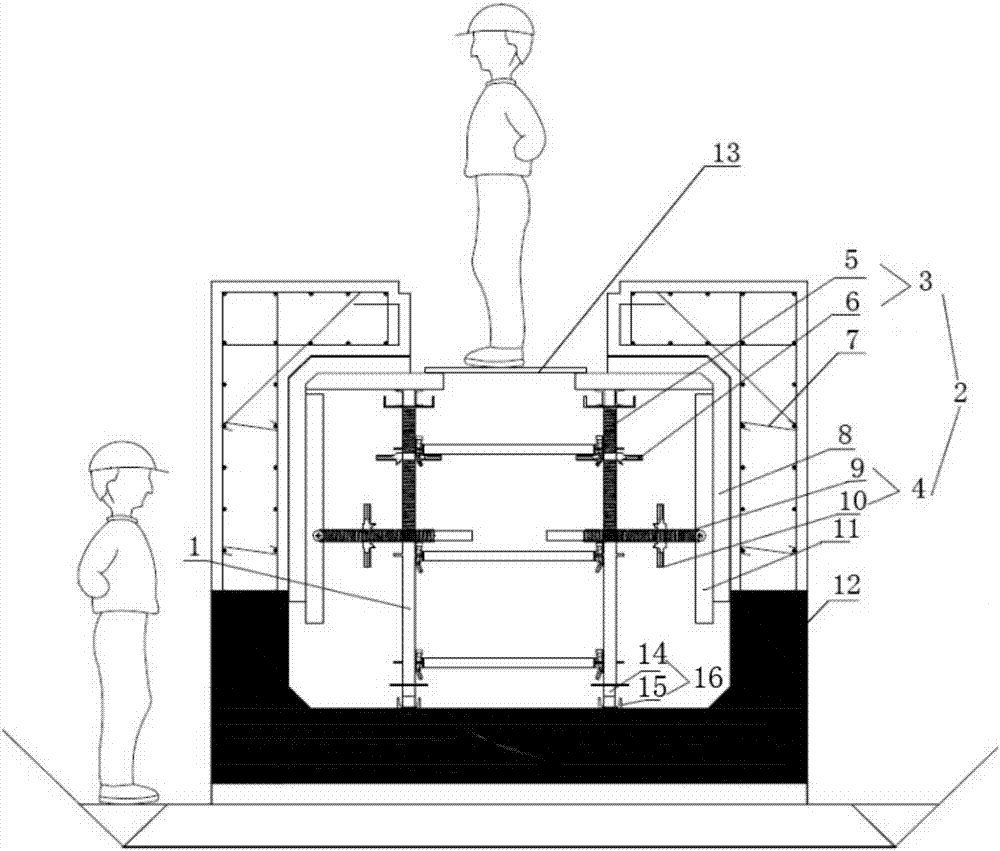

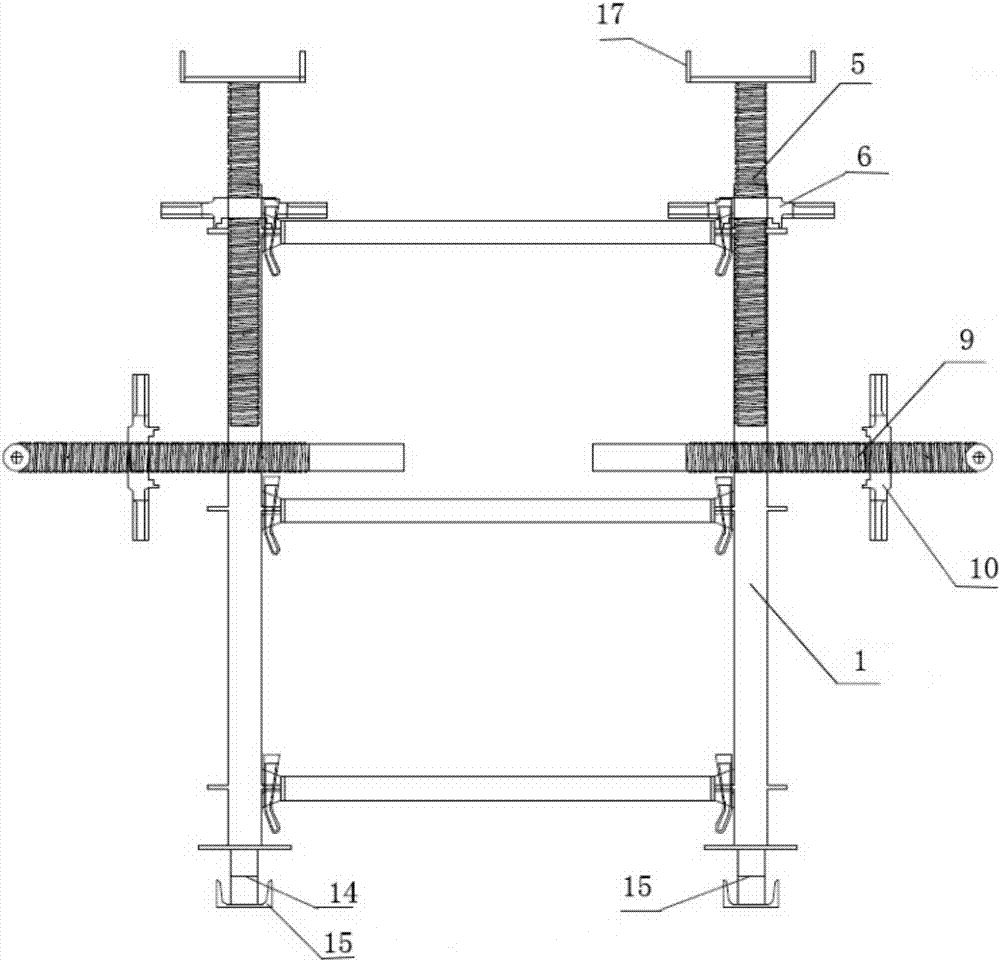

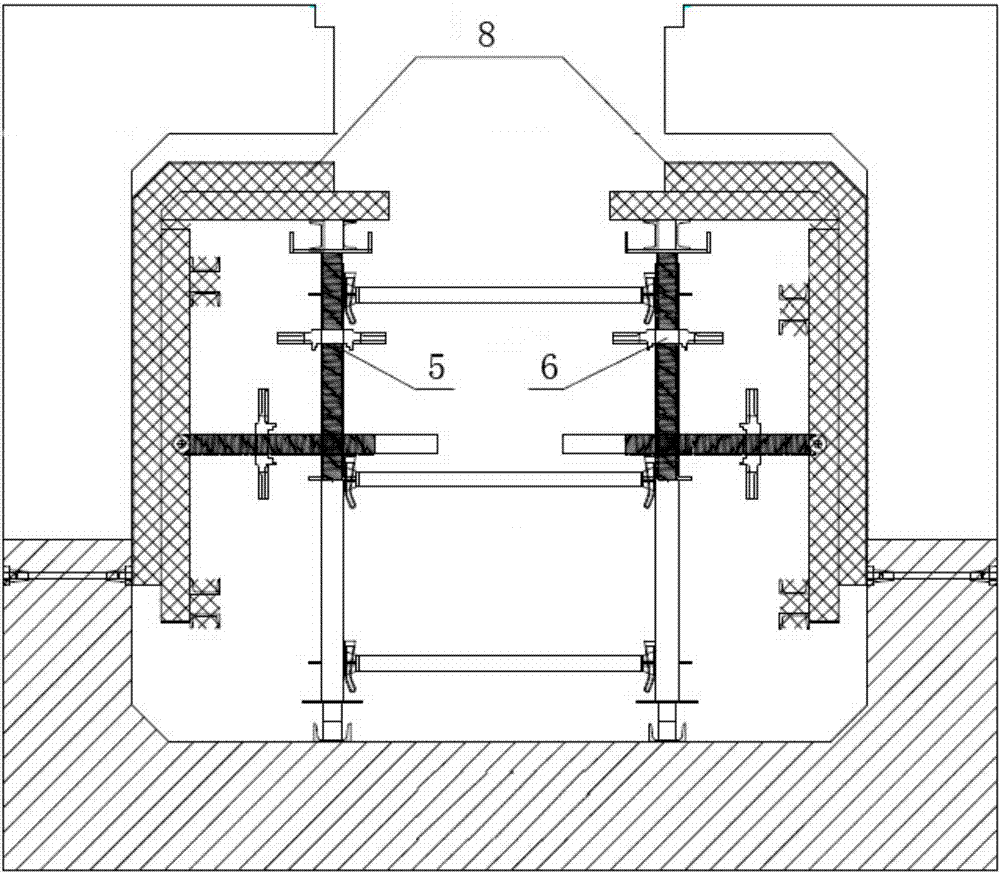

[0053] Such as figure 1 , 2, a scalable mobile formwork drive system comprising:

[0054] The main frame 1, the moving parts 16 supporting the moving of the main frame 1 on the carrier (the cast foundation 12 in this embodiment) are installed under the main frame 1, and the moving parts 16 include rollers 14 and guide rails 15, The roller 14 is installed on the lower end of the main frame 1, the guide rail 15 is installed on the carrier, and the roller 14 (the roller 14 is a universal wheel) fits in the guide rail 15;

[0055] An adjustment mechanism 2, the adjustment mechanism 2 is installed on the main frame 1, and can be withdrawn or withdrawn from the main frame 1, and the adjustment mechanism is used for installing the formwork.

[0056] In this embodiment, the adjustment mechanism 2 includes a lifting part 3 and a translation part 4, and the lifting part 3 and the translation part 4 are both threaded connection mechanisms.

[0057] The lifting part 3 includes:

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com