A Dry Venturi Paint Spraying System

A venturi and dry technology, applied in spray booths, spray devices, etc., can solve the problems of poor working environment of paint mist trapping box, poor working environment of paint mist trapping box, low investment and so on, so as to reduce cleaning and maintenance. Work load, reduce pollution and energy consumption, and facilitate the effect of walking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

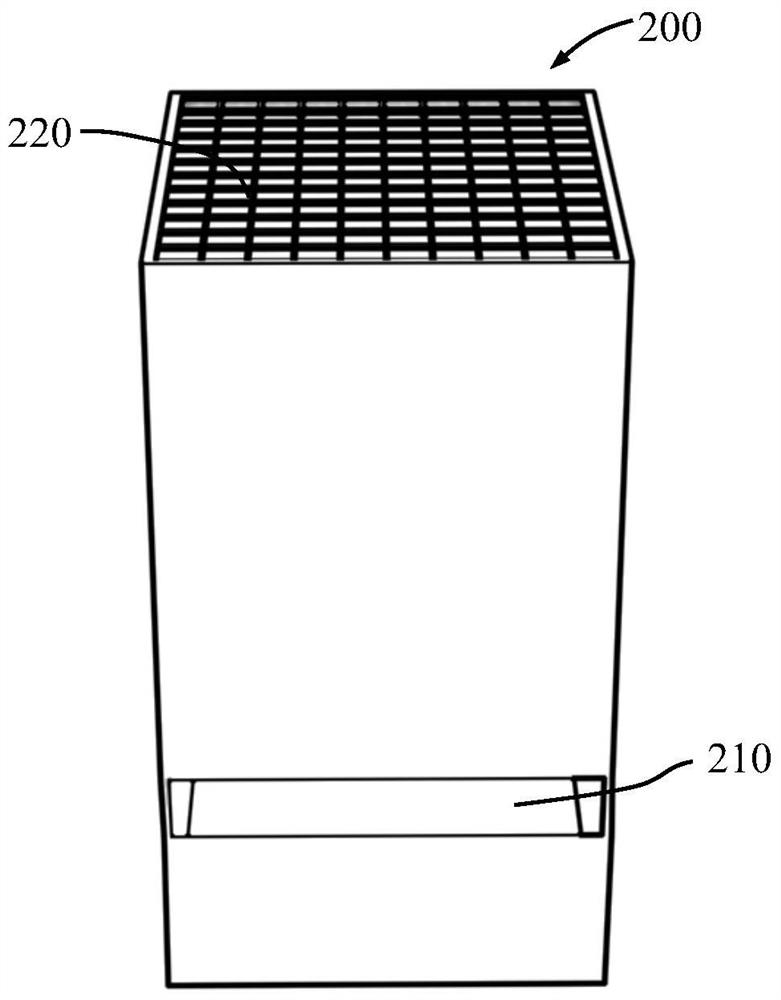

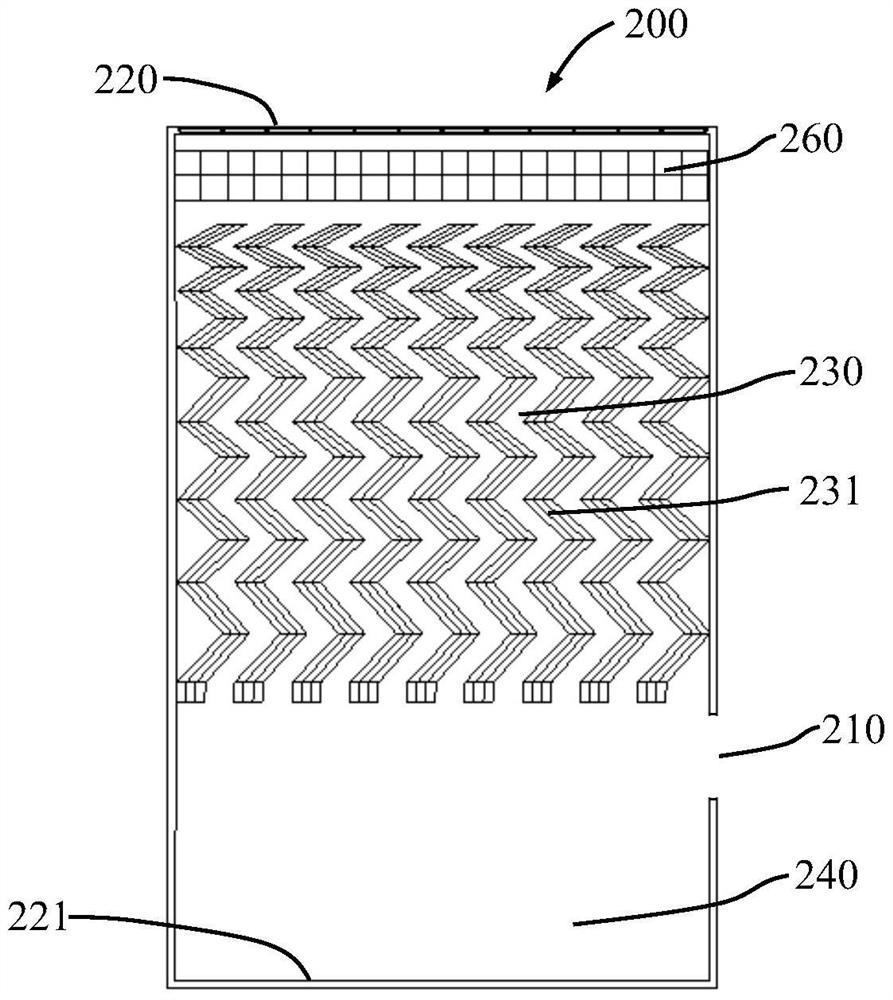

[0072] Such as image 3 As shown, nine paint mist trapping units 231 of the same size and shape are set in the paint mist trapping chamber 230 of this embodiment. The paint mist trapping unit is a corrugated plate structure with 13 bends, and each paint mist trap The capture unit has 1 air drainage surface and 13 bending surfaces. The bending angle of the bending surface gradually increases along the mainstream direction of the air. The 9 paint mist capture units are arranged parallel to the mainstream direction of the air, parallel to each other and Evenly distributed with equal gaps in between. The gap between two adjacent paint mist capture units forms an air flow channel with 13 bends. Since the bending angle of the paint mist capture units along the mainstream direction of the air gradually increases, the two paint mist capture units The width of the bent air flow channel formed by the gap between them also gradually narrows along the air main flow direction. The paint ...

Embodiment 2

[0074] Such as Figure 4 As shown, several rows of paint mist collection units 231 are arranged in the paint mist collection chamber of the present embodiment, and the distance between the paint mist collection units in the same row is the same. The bottom five rows of paint mist collection units have the same size and equal row spacing, and the opening direction of the last row of paint mist collection units forms an angle of 60 to 90 degrees with the opening direction of the next row of paint mist collection units. Among the bottom five rows of paint mist collection units, the space directly below the paint drainage head of the last row of paint mist collection units is the gap between the next row of paint mist collection units. The size of the paint mist collecting units in the upper four rows is smaller than that in the lower five rows, and the distance between the paint mist collecting units in the same row and the distance between two rows are also smaller than those in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com