Grading paint mist collector and its application

A graded, paint mist technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of low paint mist capture efficiency, large energy consumption, large wind resistance, etc., to improve the capture capacity, The effect of reducing the number of replacements and improving the absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

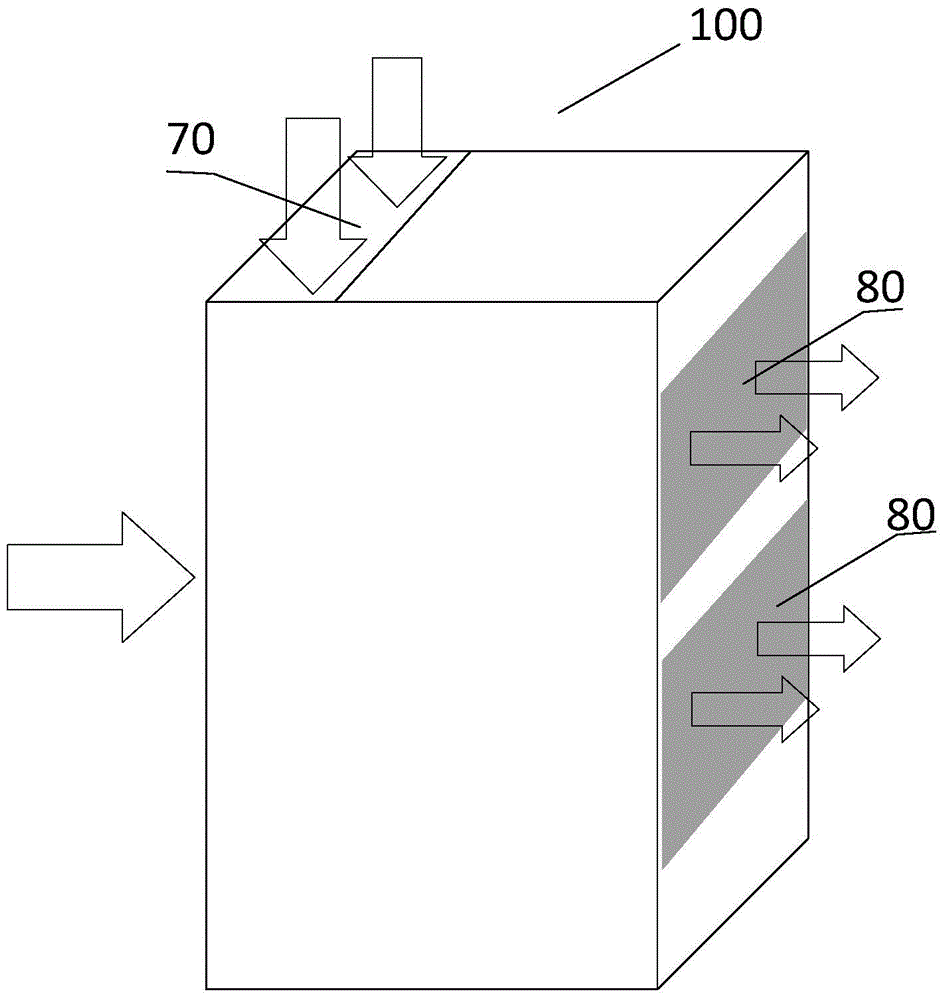

[0040] image 3 It is a schematic diagram of the appearance and structure of the dry paint mist collection and filtration device.

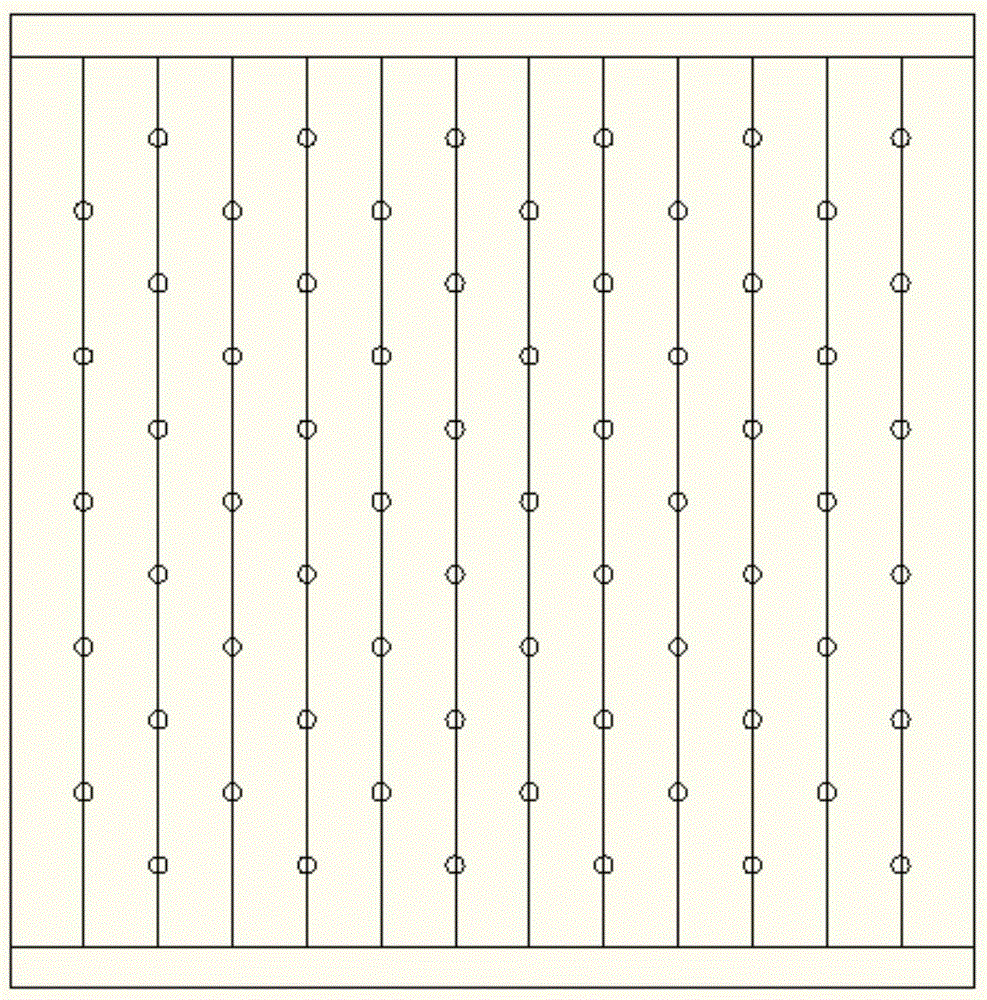

[0041] Figure 4 It is a schematic diagram of the structure of the dry paint mist collection and filtration device to remove the top plate.

[0042] Figure 5 It is a schematic diagram of the cross-sectional structure of the dry paint mist collection and filtration device.

[0043] Such as image 3 , Figure 4 and Figure 5 As shown, the dry paint mist collection and filtering device 100 has a box structure, each box is an independent unit, the outside is made of cardboard material, and the inside is a composite three-dimensional flow equalization interception filter structure.

[0044] The dry paint mist collection and filtering device 100 includes: a first graded paint mist collection module 10, a second gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com