A multi-stage paint mist trapping device and method for trapping and separating overspray

An overspray, multi-stage technology, applied in the direction of spraying devices, can solve the problem of difficulty in capturing small and light overspray particles, the space of the paint mist collection unit is not utilized, and the assembly of the paint mist collection device takes a long time To achieve the effect of improving the capture capacity, improving the utilization rate of internal space, and balancing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

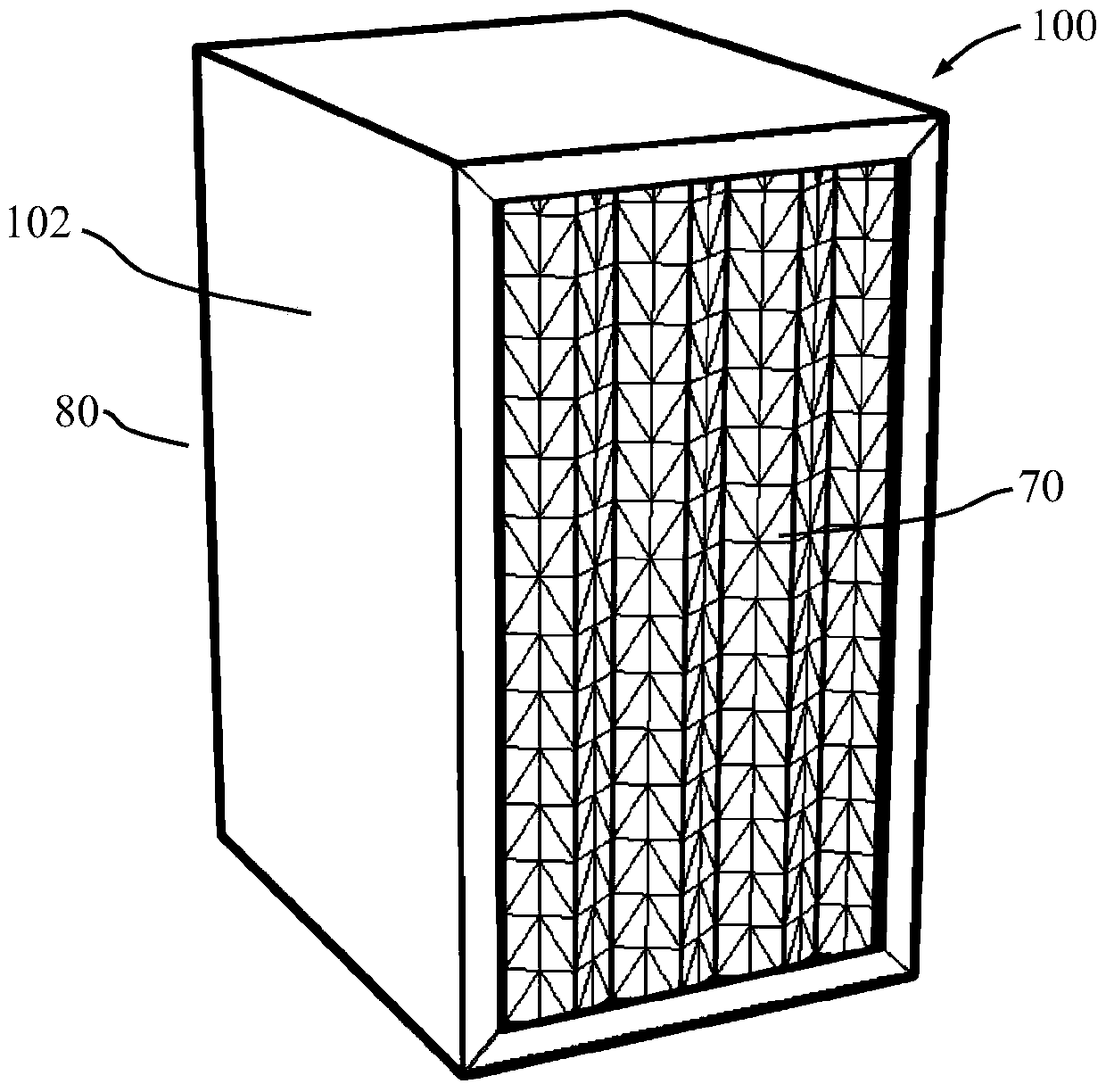

[0059] like image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, the present embodiment provides a multi-stage paint mist collection device 100, the device casing 102 is in a box structure, and the device casing 102 is made of low-value hard material, and cardboard material can be used. Each paint mist collection device is an independent unit, and the paint mist collection device sequentially includes: an air inlet 70 , a paint mist collection chamber 101 , a final filter layer 170 , and an air outlet 80 .

[0060] Because the shape of the paint mist collection device is like a box structure, painting practitioners also call it "paint mist collection box", and the name "paint mist collection box" is also used in some places in this article.

[0061] The air inlet 70 is arranged on one side of the paint mist trap, and the air outlet 80 is arranged on the opposite side. One side of the paint mist collection chamber 101 is connected to the air inlet 70, and the ...

Embodiment 2

[0088] like Figure 8 As shown, the paint mist collection unit arranged in the multi-stage paint mist collection device of this embodiment is a flat structure, and the layout and working principle of the paint mist collection unit are similar to those of Embodiment 1, and will not be described in detail here. stated. Components with the same functions use the same symbols as in Embodiment 1 in this embodiment.

[0089] like Figure 9 As shown, the dry paint spraying system provided in this embodiment mainly includes the following parts: air inlet pipe 10, dynamic pressure chamber 11, static pressure chamber 12, paint spraying room 20, spraying robot 24, conveying system 22, spray booth paint mist collection chamber 30, a multi-stage paint mist collection device 100 and an exhaust fan 50, wherein the above-mentioned multi-stage paint mist collection device 100 is arranged in the paint mist collection chamber 30 of the spray booth.

[0090] The working process of the dry spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com