Molten aluminum two-man ladle

A technology of aluminum water ladle and aluminum water, which is used in casting molten material containers, manufacturing tools, metal processing equipment, etc., can solve the problems of low operation efficiency of manual shaking, and achieve the effect of convenient control and high operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

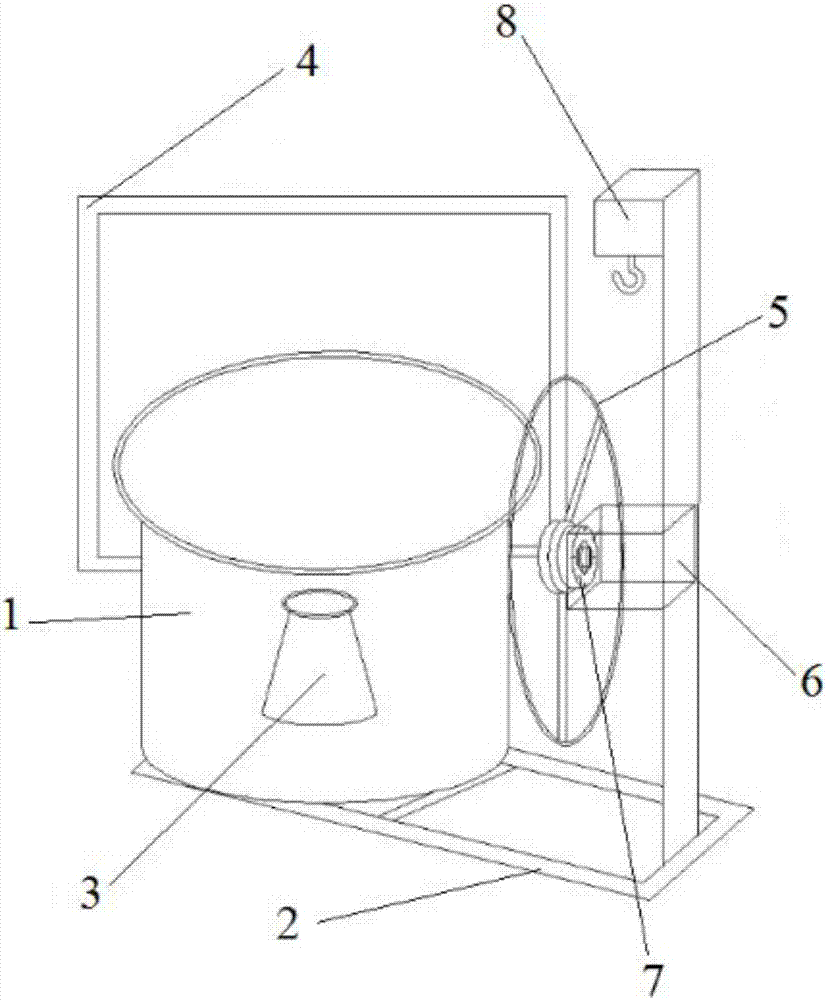

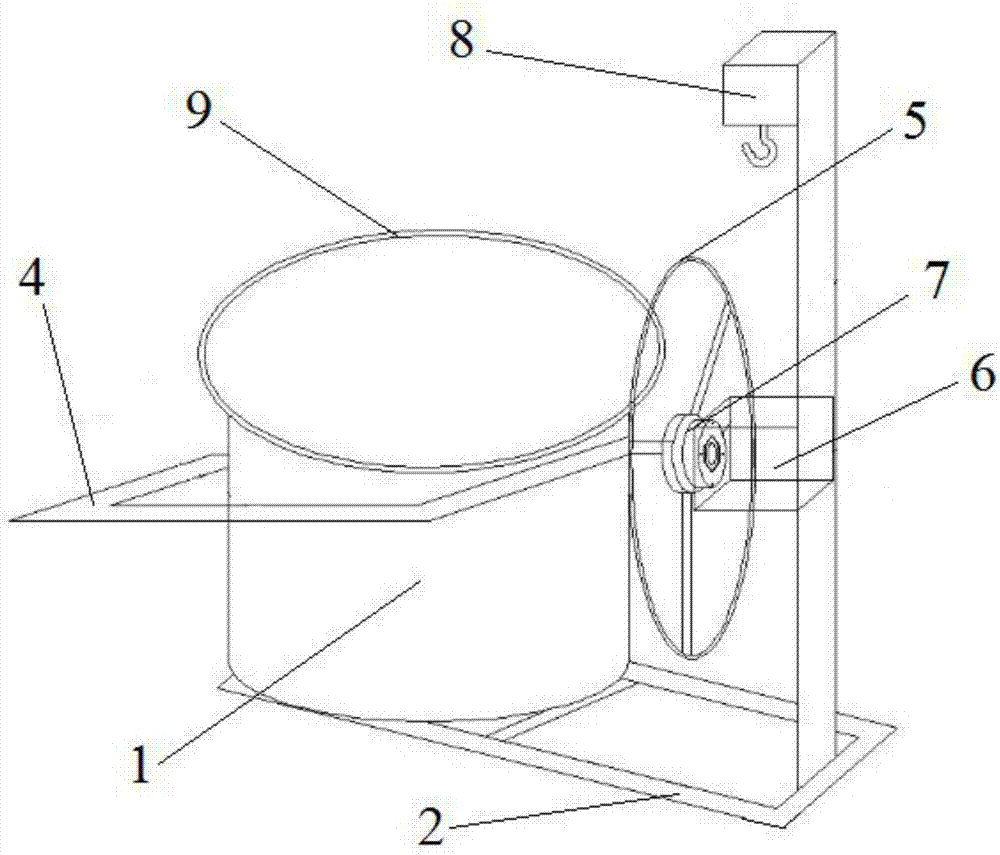

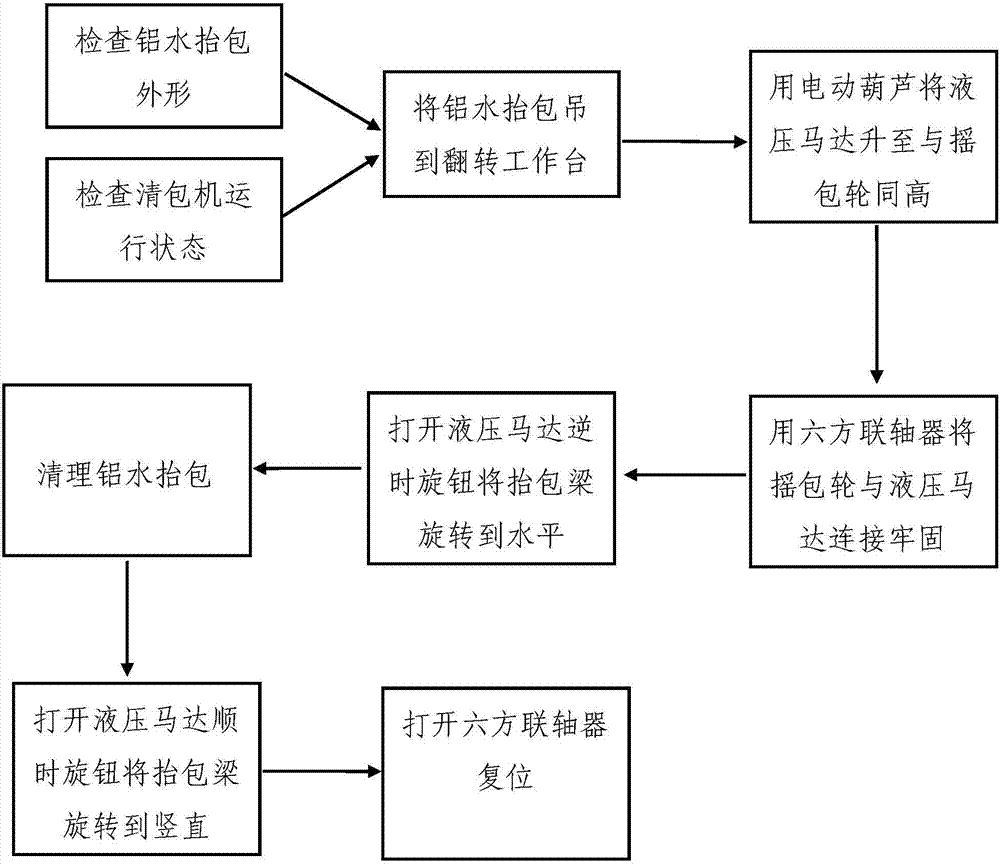

[0026] Such as Figure 1-3 As shown, this embodiment is a further detailed description of the technical principle and working process of the aluminum ladle ladle of the present invention.

[0027] Such as figure 1 As shown, this embodiment provides an aluminum ladle, which includes a ladle 1, where a ladle beam 4 is installed on both sides of the ladle 1, and a shaker wheel 5 is installed on one side of the ladle beam 4, and the aluminum ladle 1 is provided with an inverted lead port 3 on the side wall, and also includes a turning table 2. The turning table 2 includes a horizontal bracket and a vertical bracket connected to the horizontal bracket. The vertical bracket is equipped with a hydraulic motor 6 and a hydraulic motor 6 The vertical support is a sliding connection, the hydraulic motor 6 is connected to the shaker wheel 5 through a coupling, the aluminum water bag 1 is placed on a horizontal support, the top of the vertical support is provided with an electric hoist 8, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com