Concrete pavement structure and its design method based on pva and pan materials

A technology of concrete pavement and design method, which is applied to cohesive pavement paved on site, roads, roads, etc., which can solve the problems of low structural strength, fracture, water seepage, and low waterproof performance, and achieve good finish and increase flexibility , the effect of not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

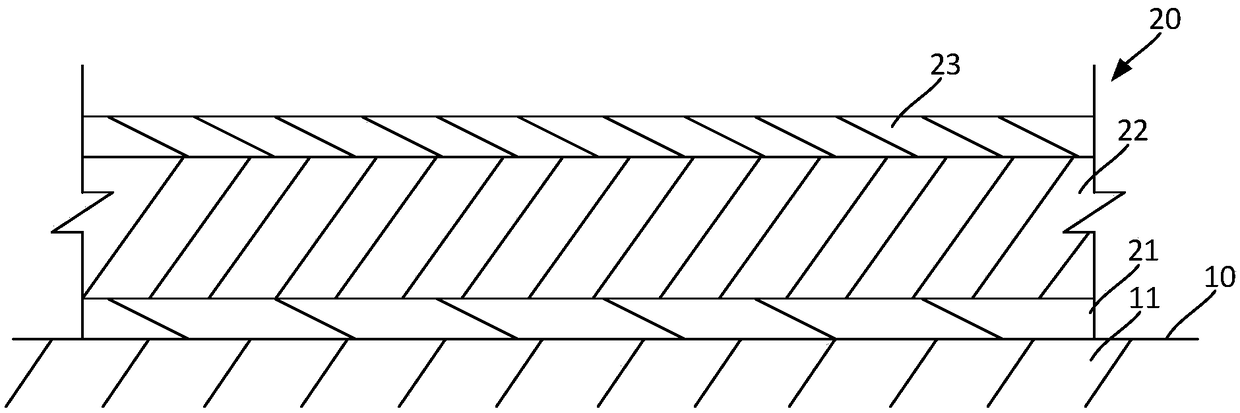

[0052] As another preferred embodiment of the present invention, the design method also includes: the design value δ of the thickness of the intermediate layer 22 obtained according to the design 2 Design the spacing of the double-layer bamboo reinforcement structure:

[0053] In the double-layer bamboo-reinforced structure, the distance between the bamboo-reinforced structure at the top and the distance between the upper surface of the middle layer 22 and the distance between the bamboo-reinforced structure at the bottom and the lower surface of the intermediate layer 22 are designed as the minimum thickness of the concrete cover, so that the double-layer bamboo-reinforced structure The spacing is the thickness design value of the middle layer δ 2 The difference from twice the minimum thickness of the concrete cover. If the bamboo reinforcement structure positioned at the top is designed to be 10cm from the distance of the middle layer 22 upper surface, the bamboo reinforcem...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap