Method for dismantling concrete of dustpan feeding inlet of constructional column

A technology for structural columns and material inlets, which is applied to building structures, on-site preparation of building components, formwork/formwork/work frames, etc., can solve problems that affect construction progress, consume labor, and are not environmentally friendly. The effect of construction quality, improvement of construction efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

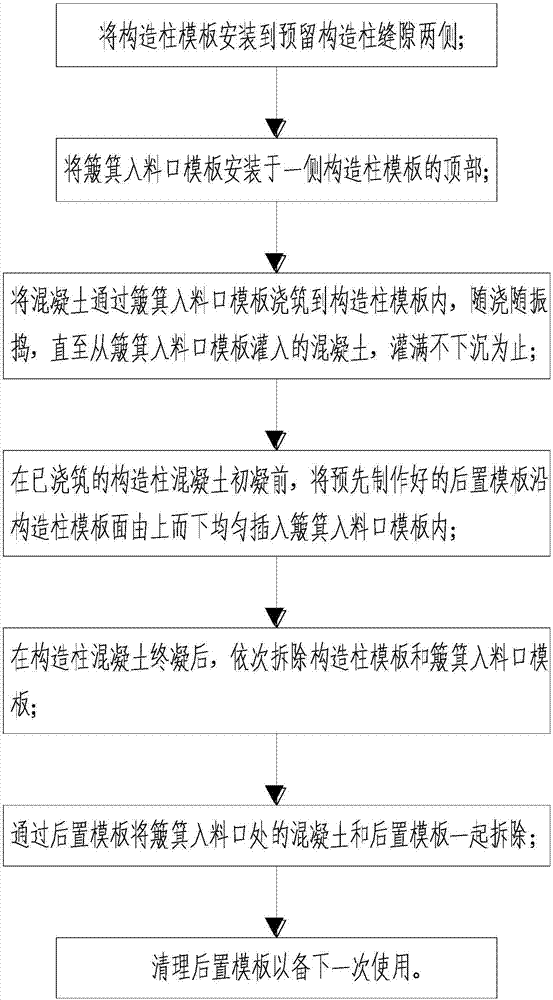

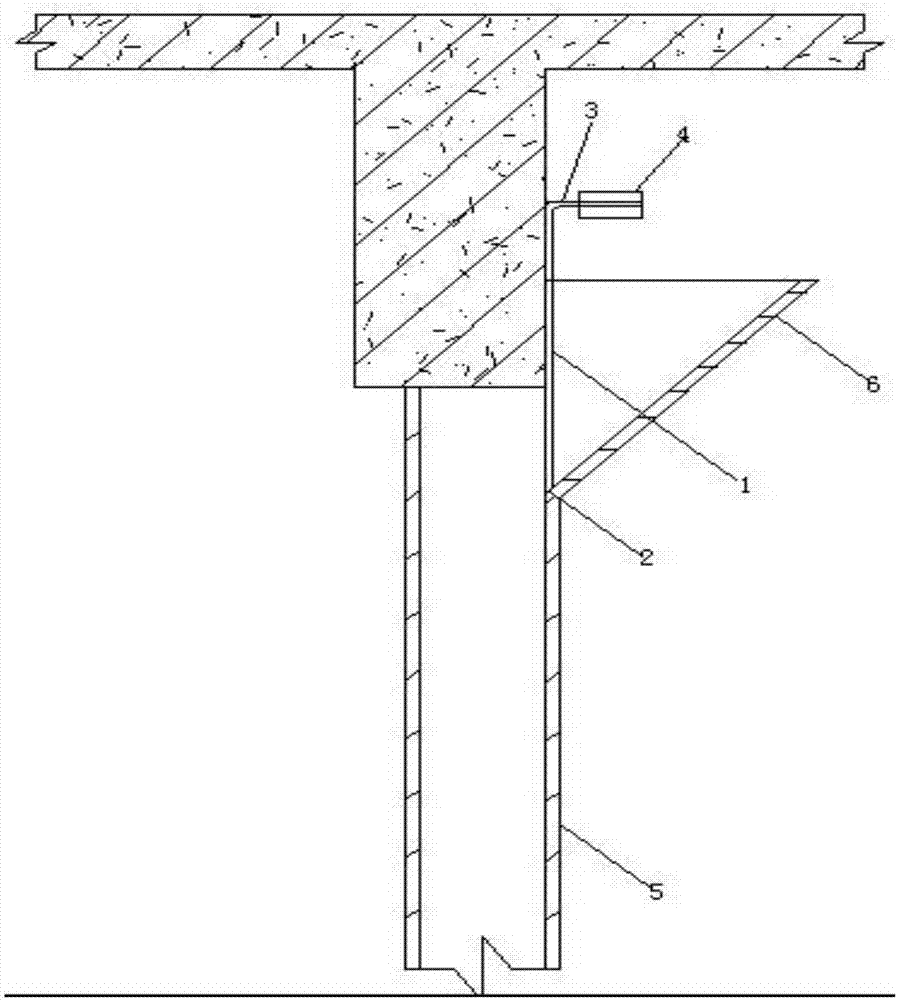

[0032] refer to Figure 1 to Figure 4 As shown, the construction column dustpan feed port concrete removal method in one embodiment provided by the invention comprises the following steps:

[0033] 1) Install the structural column template 5 on both sides of the reserved structural column gap;

[0034] 2) Install the dustpan material inlet formwork 6 on the top of the structural column formwork 5 on one side;

[0035] 3) Concrete is poured into the structural column formwork 5 through the dustpan feeder formwork 6, and vibrated as it is poured until the concrete poured from the dustpan feeder formwork 6 is filled and does not sink;

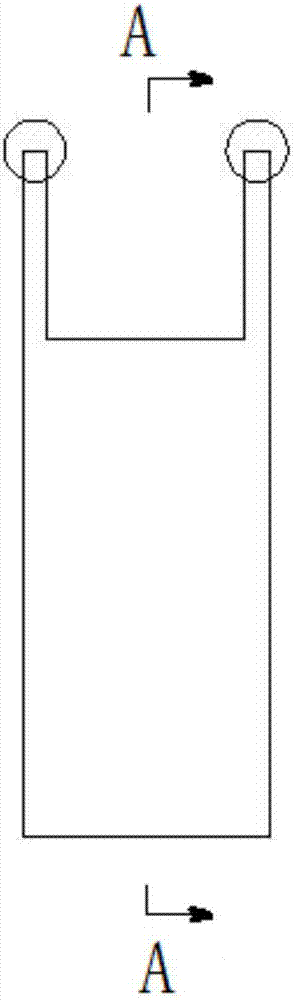

[0036] 4) Before the initial setting of the poured structural column concrete, the prefabricated rear formwork 1 is evenly inserted into the dustpan inlet formwork 6 along the structural column formwork 5 from top to bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com