Timing device mechanism

A technology of initial position and impact bar, which is applied to the direction of time indication mechanical device, mechanically driven clock, and time indication by sound mode, which can solve the problems of height increase, acceleration, and structural space increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

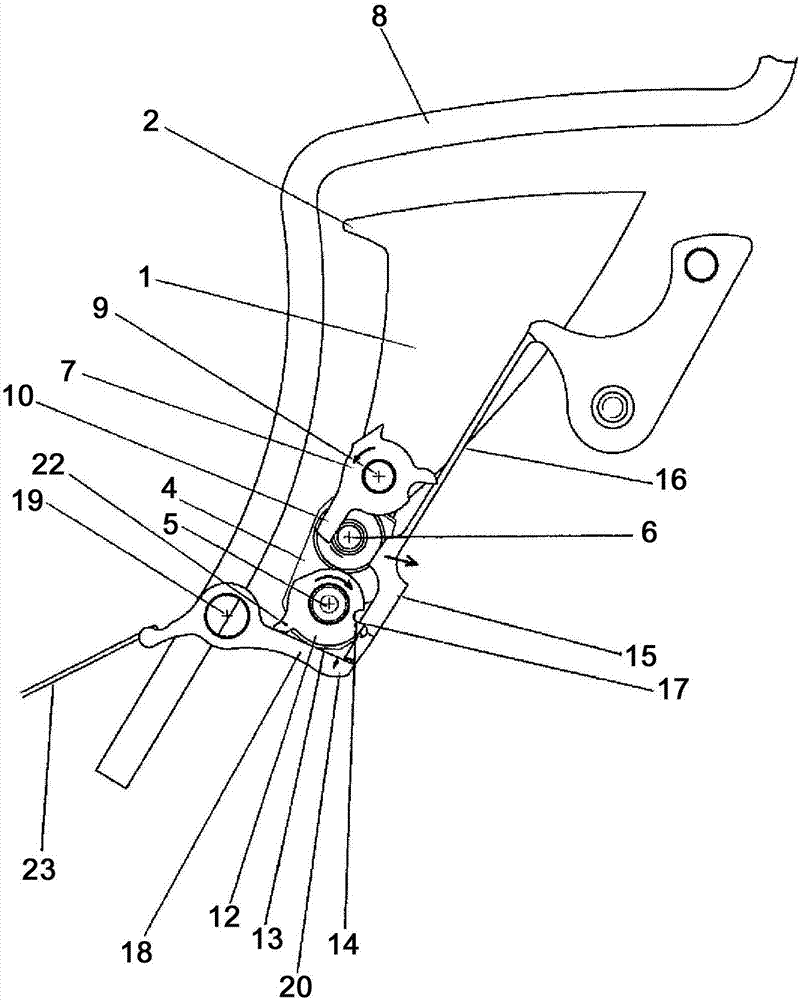

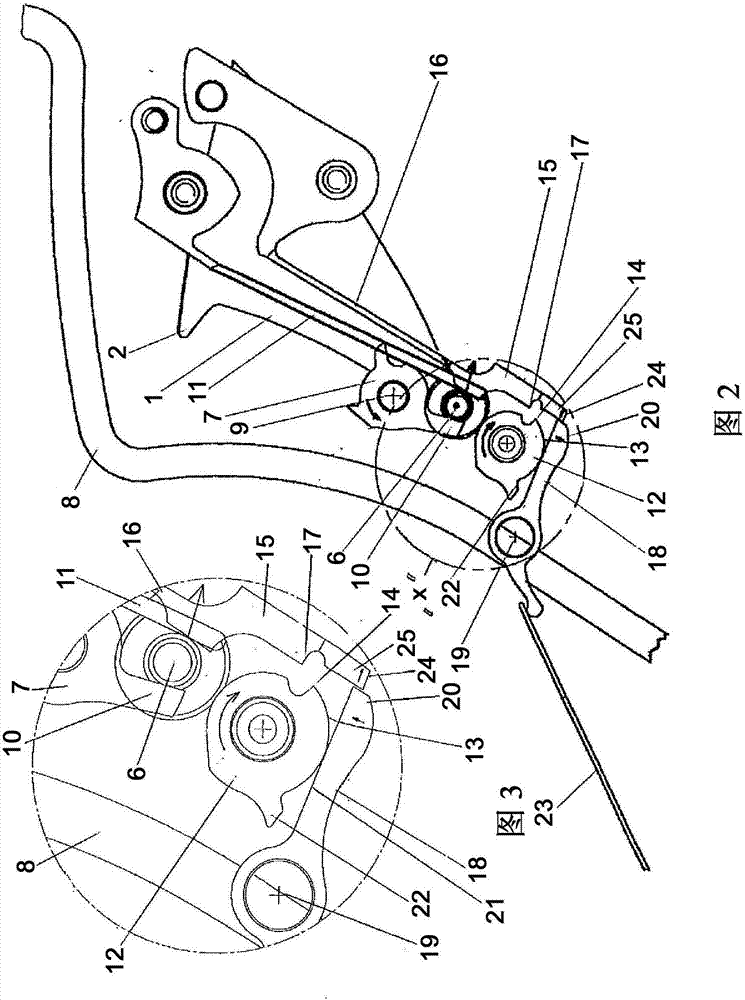

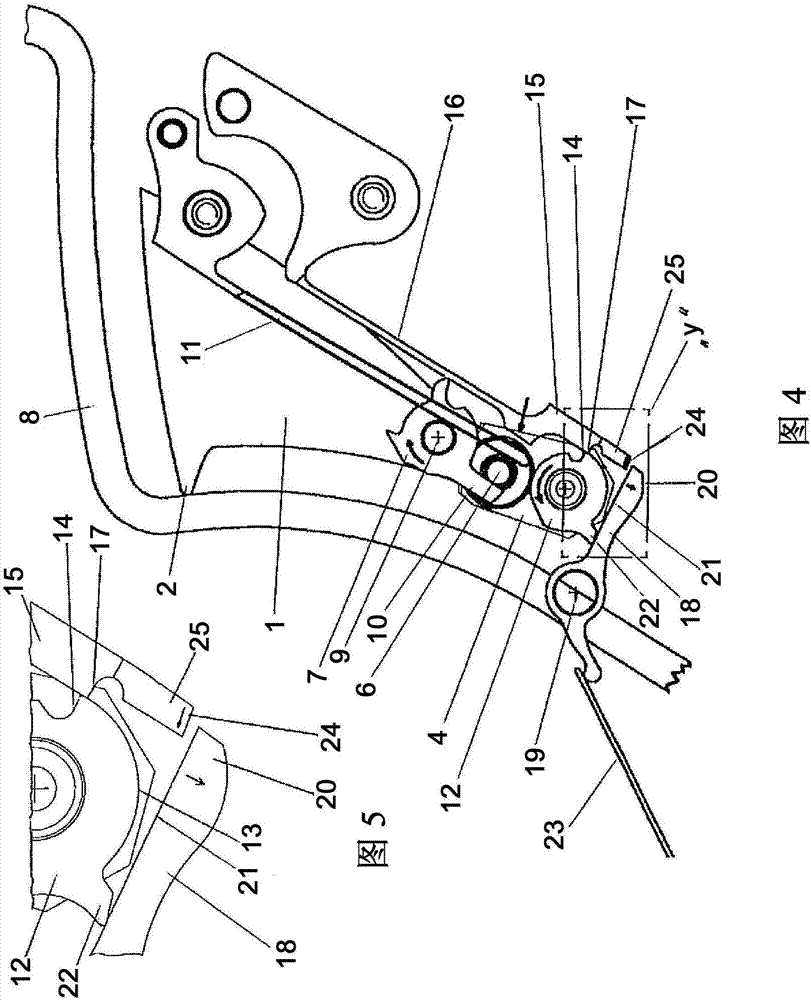

[0027] The illustrated striking mechanism for a reed watch has a striker lever 1 with a striker 2 at one end thereof. At its other end, the striker rod 1 is connected to the platform 4 at the screwed-in point 3 . At a distance parallel to the screwing point 3 , the platform 4 has a rotatably mounted hammer shaft 5 , with which the platform 4 is pivotably mounted and with which the striking rod 1 is pivotably mounted.

[0028] Coaxially with the tightening position 3, a follower pin 6 is arranged on the platform 4, and the motor 7 can drive it from the initial position ( figure 1 ) can be swiveled into the tensioned position (Figures 2 and 3). The starter 7 can be driven rotatably counterclockwise by a rake (not shown), such as a spring striking tool of a reed watch.

[0029] at the initial position ( figure 1 ) in the distance between the striking hammer 2 and the bell spring 8 is relatively small, and in the tensioned position (Fig. in the swing plane.

[0030] The actua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com