Method of suppressing light-and elevated temperature-induced degradation for multicrystalline silicon PERC (Passivated Emitterand Rear Cell)

A polysilicon and auxiliary light technology, applied in the field of solar cells, can solve the problems of affecting the performance of the cell, increasing the cell preparation process, and high cost, and achieving the effects of wide popularization and application value, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

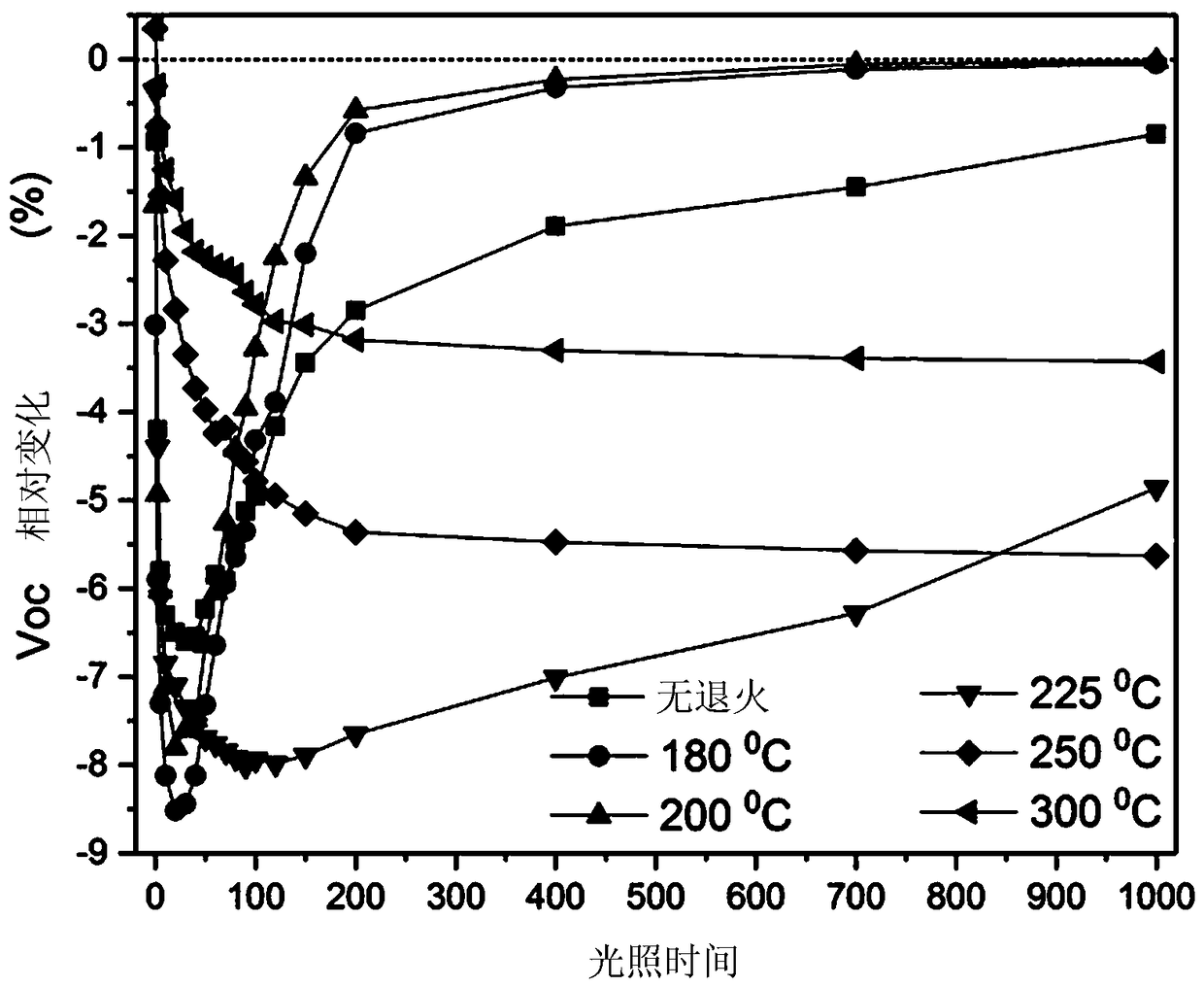

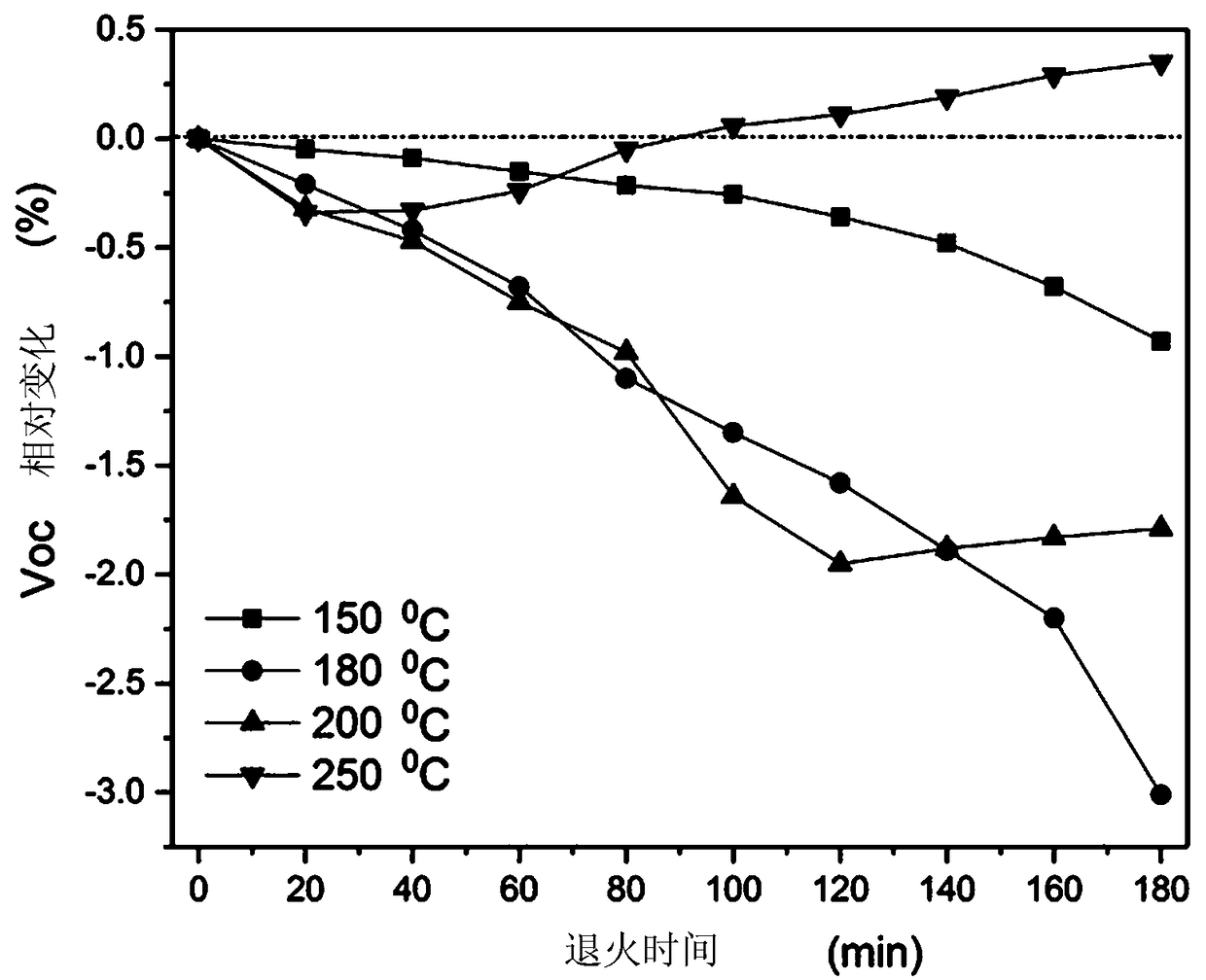

[0012] The method for suppressing thermally assisted light-induced attenuation of polysilicon PERC cells described in this embodiment includes the following specific implementation steps:

[0013] 1) Prepare polysilicon PERC cells: the cells used in the experiment are commercial products purchased from the market, and the basic parameters are: size 156×156mm 2 , conversion efficiency 19.1%, open circuit voltage 0.64V, short circuit current 36.2mA / cm 2 . Cell structure includes front electrode, silicon nitride anti-reflection layer and passivation layer, phosphorus diffusion layer, p-type polysilicon, aluminum oxide passivation layer, silicon nitride protective layer, back electrode;

[0014] 2) Low-temperature annealing treatment without light: put the cells in step 1) into an ordinary annealing furnace with no light and an air atmosphere. 300°C, the annealing time is: 20min, 40min, 60min, 80min, 100min, 120min, 140min, 160min, 180min;

[0015] 3) Heat-assisted light-induce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com