Manufacturing method of intraocular lens

A technology of intraocular lens and manufacturing method, which is applied in the directions of intraocular lens, prosthesis, additive processing, etc., can solve the problem that the intraocular lens cannot be used individually, and achieve the effect of individualized use and improve the visual quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0044] Due to the current mass production of intraocular lenses, it is difficult to adapt to individualized eye problems of patients, and patients have poor experience in use. The invention provides a method for manufacturing intraocular lenses.

[0045] The method and corresponding equipment will be described in detail below through basic design, extended design and replacement design.

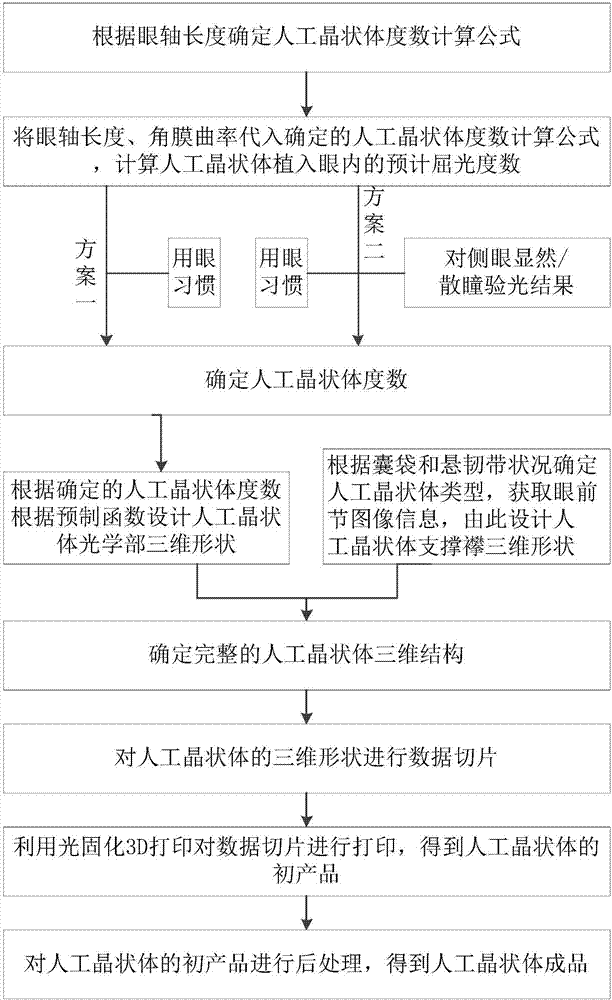

[0046] A method of making an intraocular lens, such as figure 1 As shown, the steps include:

[0047] Step 110, determine (select) the degree of intraocular lens according to the obtained eye examination data;

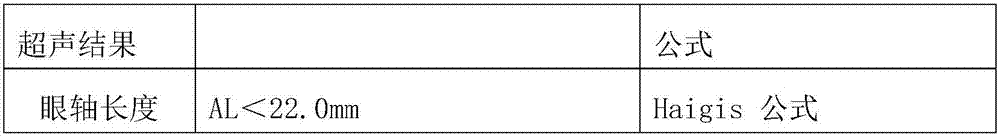

[0048] The eye examination data may include: axial length of the eye, corn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Light wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com