Crushing type winnowing machine

A winnowing machine and crushing technology, applied in the field of metallurgy, can solve the problems of low total process yield, many types of process equipment, and large space occupation, so as to achieve less equipment types, low process loss rate, and large space occupation little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

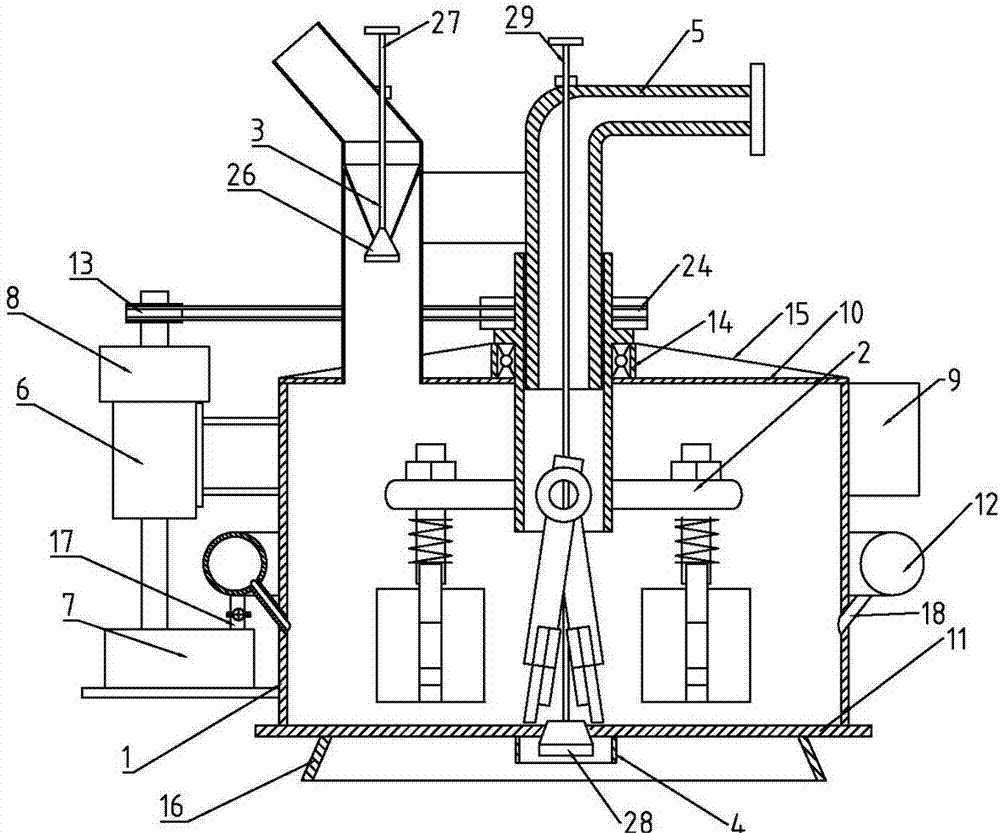

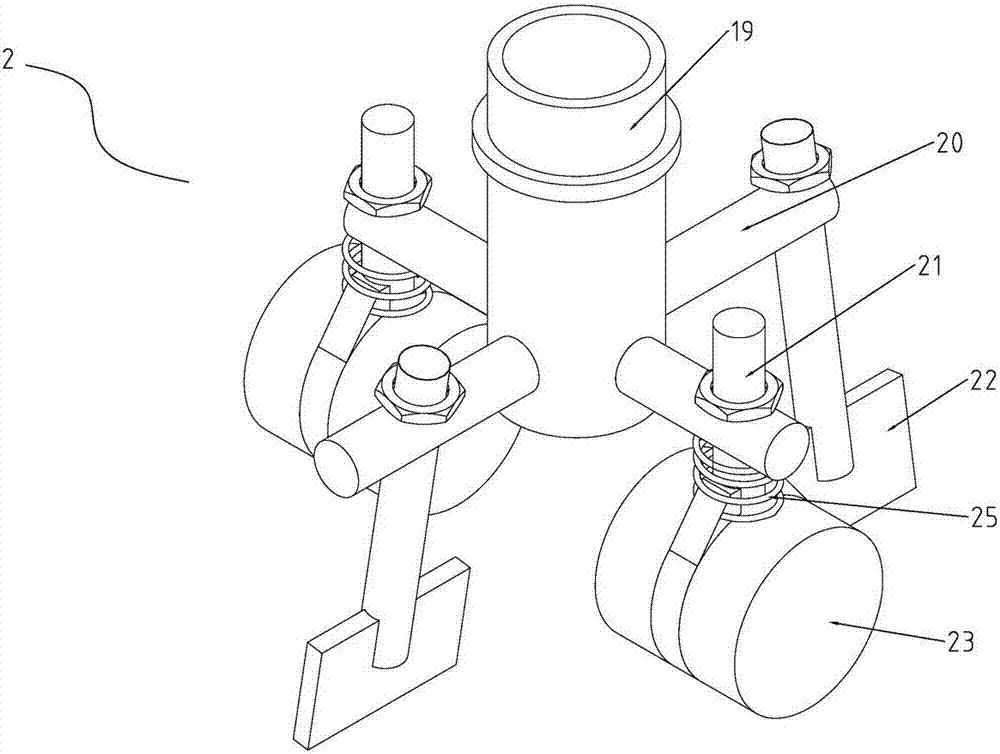

[0016] Embodiment 1: The inner diameter of the box body cylinder 1 of the present invention is 1.5 meters, the inner width height of the box body 1 is 0.78 meters, the power of the drive motor 6 is 4.5kW, the air volume of the centrifugal blower 7 is 50 cubic meters per minute, and the large pulley is 25 meters. The rotating speed is 50 revolutions per minute, and the inner diameter of the outlet discharge pipe 5 is 100 mm. When in use, first connect the external bag filter to the outlet discharge pipe 5, and connect the external receiving tank or bag to the lower discharge part. 4 Connect well, connect the external feeding facility with the receiving part 3 of the receiving assembly fixed on the box body, then close the lower receiving cone valve 26 and discharge cone valve 28, open the air inlet control valve, and then start Drive motor 6, at this moment, drive motor 6 drives centrifugal blower 7 to surround pipe air supply and blows air in casing 1 through air inlet connecti...

Embodiment 2

[0017]Embodiment 2: When the present invention is in use, first connect the external box-type bag filter with the outlet discharge pipe 5, connect the external receiving tank or bag with the lower discharge part 4, and connect the external After the feeding facility is connected to the material receiving port of the material receiving component 3 fixed on the box body 1, the gas discharge port of the box-type bag filter is connected to the suction port of the centrifugal blower 7 of the equipment through the circulating air duct (In this way, the wind of the centrifugal blower can be formed through the air inlet assembly, the box body 1, the air outlet discharge pipe 5, the bag dust collector of the box type 1, and the circulating air duct and then enter the suction port of the centrifugal blower 7 airtight cycle, which can avoid gas leakage), close the lower receiving cone valve 26 and discharge cone valve 28, open the air inlet control valve, and then start the drive motor 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com