Assistant melting mechanism of cylinder dyeing machine

A dyeing machine and drum technology, applied in the field of drum dyeing machines, can solve the problems of high concentration and poor dilution effect, and achieve the effect of uniform addition and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

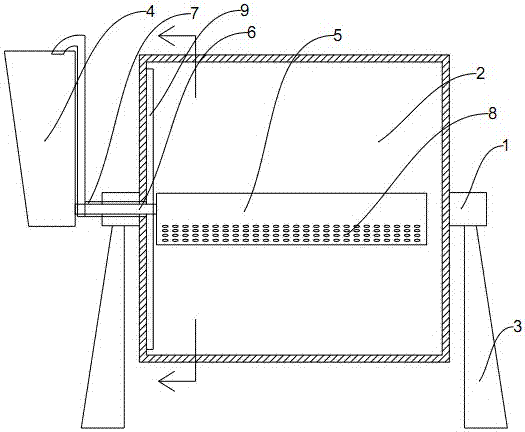

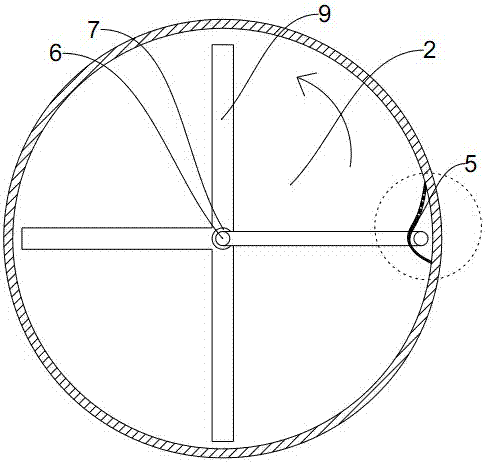

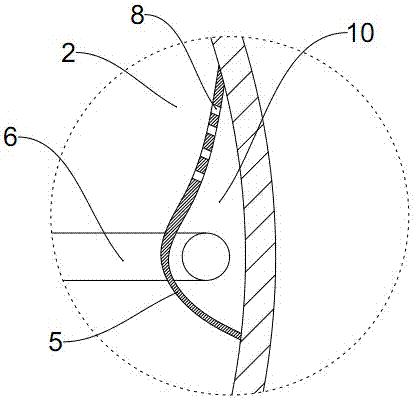

[0017] The auxiliaries and materials mechanism of a drum dyeing machine described in this embodiment includes a drum 2 and a frame 3. The drum 2 is connected to the frame 3 through a main shaft 1, and a liquid inlet is arranged axially in one of the main shafts 1. The pipe 6 and the liquid inlet pipe 6 extend from the outside of the drum 2 to the inside of the drum 2. The liquid inlet pipe 6 outside the drum 2 is connected with a chemical hopper 4, and a chemical material plate 5 is arranged on the circumferential side wall inside the drum 2. A closed cavity 10 is formed between the material plate 5 and the circumferential side wall of the drum 2, and the liquid inlet pipe 6 inside the drum 2 extends to the inside of the cavity 10. Taking the rotation direction of the drum 2 as a reference, when the drum 2 rotates The chemical material plate 5 at the front end of the direction is provided with some liquid outlet holes 8, and the nozzle of the liquid inlet pipe 6 in the cavity 1...

Embodiment 2

[0019] Such as figure 1 , figure 2 , image 3 As shown, the auxiliary material mechanism of a drum dyeing machine described in this embodiment includes a drum 2 and a frame 3, and the drum 2 is connected to the frame 3 through a main shaft 1, and is axially arranged in one of the main shafts 1 There is a liquid inlet pipe 6, and the liquid inlet pipe 6 extends from the outside of the drum 2 to the inside of the drum 2, the liquid inlet pipe 6 outside the drum 2 is connected to the chemical hopper 4, and the chemical material is arranged on the circumferential side wall inside the drum 2 A closed cavity 10 is formed between the plate 5, the material plate 5 and the axial side wall of the drum 2, and the liquid inlet pipe 6 inside the drum 2 extends to the inside of the cavity 10, taking the rotation direction of the drum 2 as a reference, in The chemical material plate 5 at the front end of the rotating direction of the drum 2 is provided with a plurality of liquid discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com