Lift cylinders for agricultural machinery

A technology for agricultural machinery and oil cylinders, applied in the direction of fluid pressure actuating devices, etc., can solve the problems of shortening the life of the oil cylinder, leakage of the piston gap, and oil cylinder failure, etc., so as to reduce the failure rate of the oil cylinder, avoid early damage, and improve the life of the oil cylinder. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further illustrated in a non-limiting manner below in conjunction with the accompanying drawings and examples.

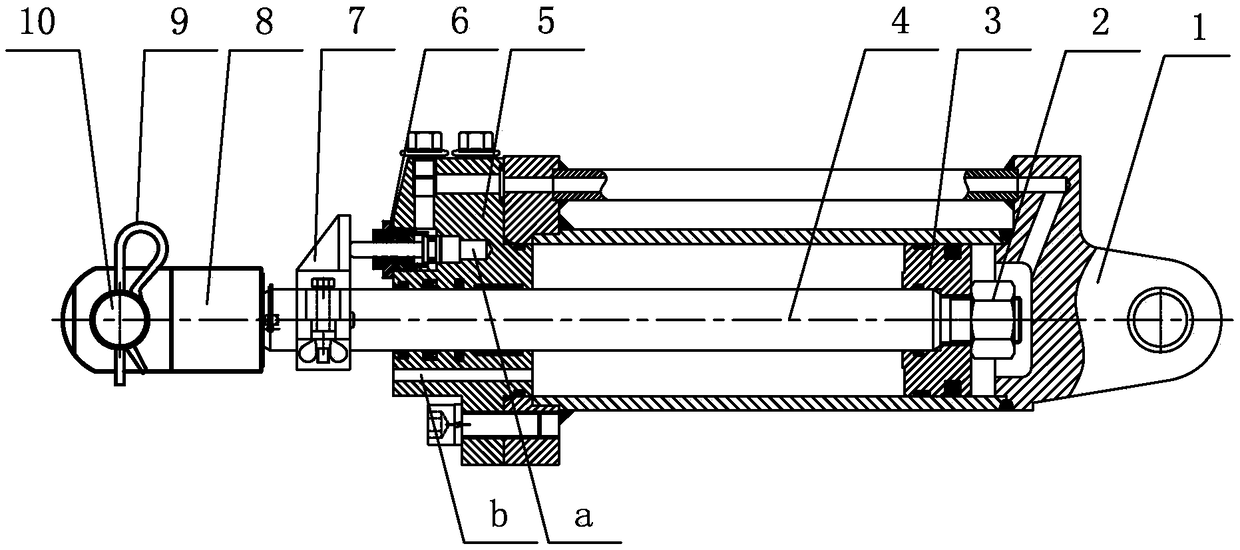

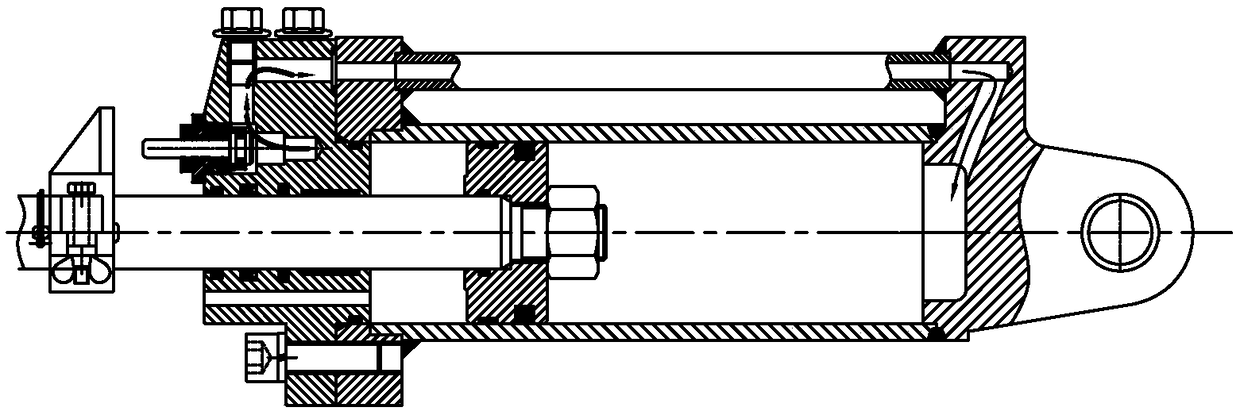

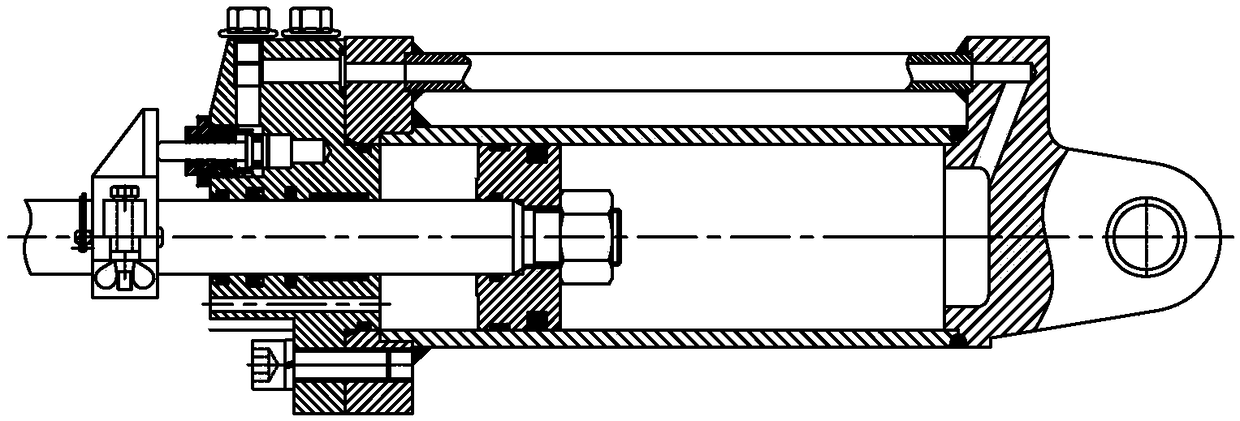

[0021] Such as figure 2 As shown, the lift cylinder for agricultural machinery of the present invention comprises: cylinder barrel 1, cylinder head 5, piston 3, piston rod 4, and piston 3 is positioned at the oil cylinder inner cavity that cylinder head 5 and cylinder barrel 1 surround, and piston 3 will oil cylinder The inner cavity is divided into a rod cavity and a rodless cavity. The piston rod 4 passes through the cylinder head 5 and is connected to the piston 3, and is locked by the lock nut 2. A limit stopper 7 is provided on the outer rod section of the piston rod 4, and the cylinder The cover 5 is provided with a rod chamber oil port b and a rodless chamber oil port a, the rod chamber oil port b communicates with the rod chamber, and the rodless chamber oil port a communicates with the rodless chamber through the rodles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com