Vibration absorbing mechanism for converting complex vibration into triaxial reciprocating vibration

A shock-absorbing mechanism, three-axis technology, applied in non-rotational vibration suppression, spring/shock absorber, vibration suppression adjustment, etc., can solve the problems of reduced navigation accuracy of inertial navigation system, damage to inertial navigation devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

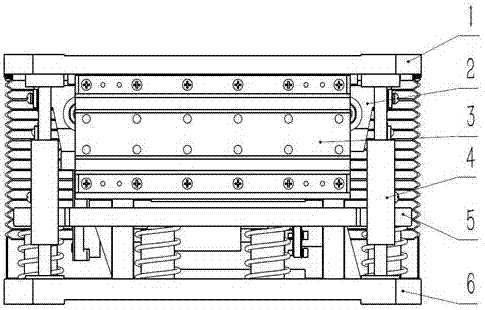

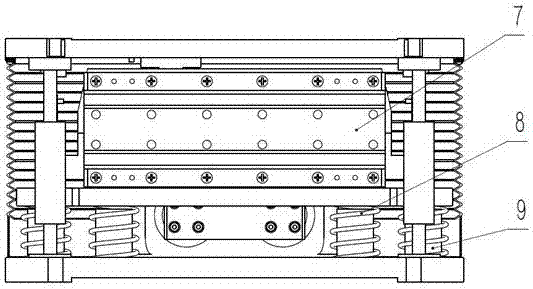

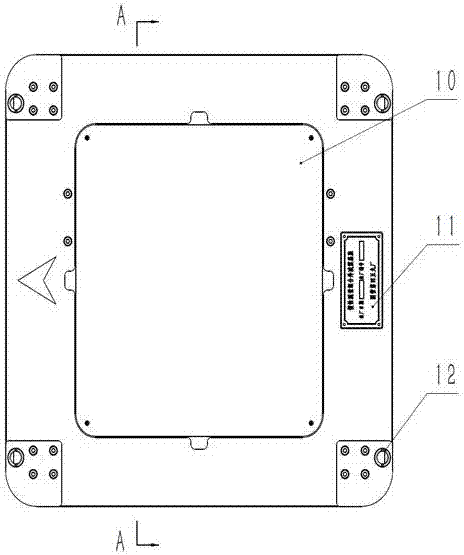

[0023] A damping mechanism that converts complex vibrations into triaxial reciprocating vibrations is mainly composed of an upper panel 1, an upper frame 2, a lower frame 5, a lower panel 6, an elastic system and a damping system, wherein the elastic system consists of a transverse reed group 3. The longitudinal reed group 7, the spring 8 and the vertical reed group 15 are formed, and the damping system is composed of the vertical damping rod 4, the transverse damping rod 13 and the longitudinal damping rod 16. The shock absorbing mechanism adopts a stepped staggered structure layout, and the lower panel 6, the lower frame 5, the upper frame 2, and the upper panel 1 are used as four staggered steps from bottom to top to form the main frame of the shock absorbing mechanism; 3, longitudinal reed group 7, spring 8, vertical reed group 15 etc. are installed and connected as elastic elements between each step to form the elastic system of damping mechanism; Vertical damping rod 4, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com