Enclasping mechanism, and pedal device of chair

A technology of chair furniture and clamping feet, which is applied in the field of office chairs and swivel chairs. It can solve the problems of uneven holding force, insufficient holding effect, and loss of tightening function, etc., and achieves uniform holding force up and down, and is convenient for manual operation. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] Embodiment: First define the orientation. The description of the orientation in the present invention is based on the fact that the clasping mechanism and the pedal device are installed on the chair and are in normal use. The inner sleeve is located at the lower end of the outer sleeve and the two are plugged together.

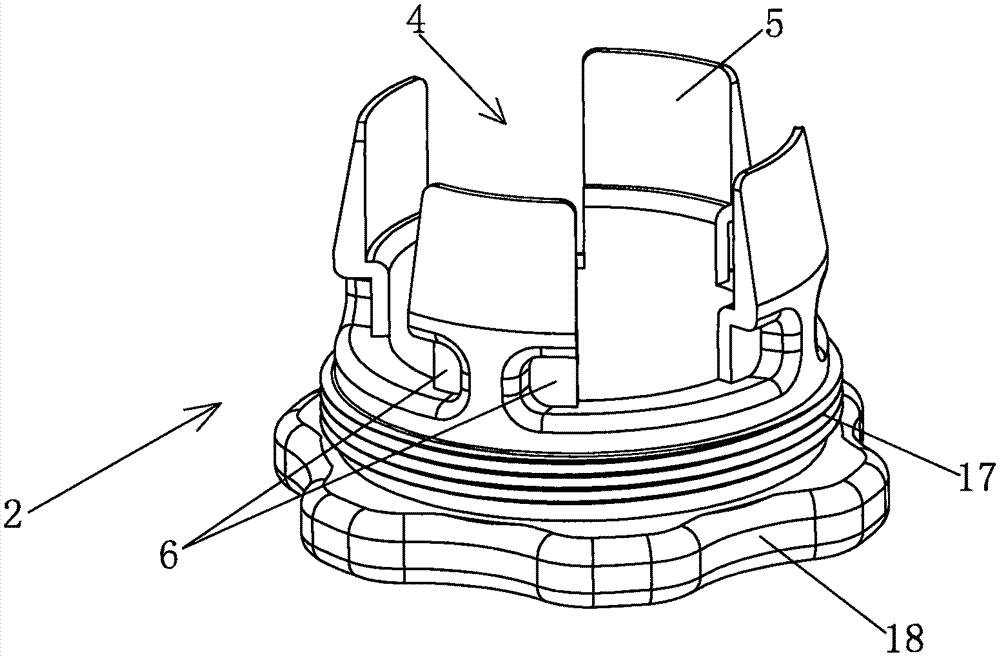

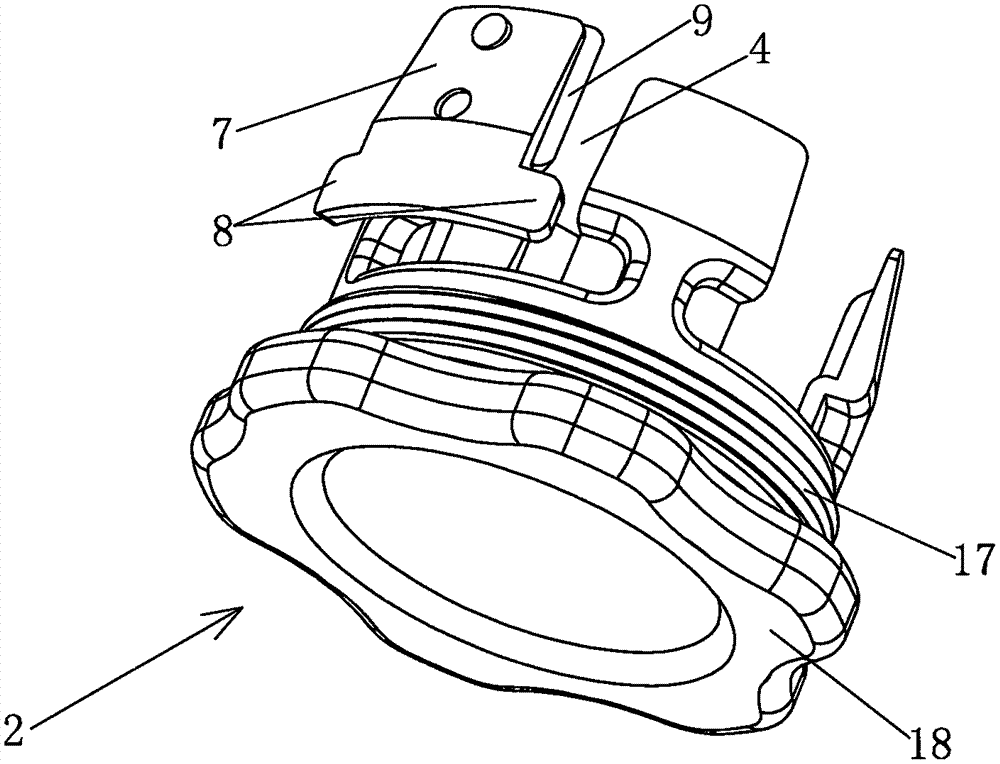

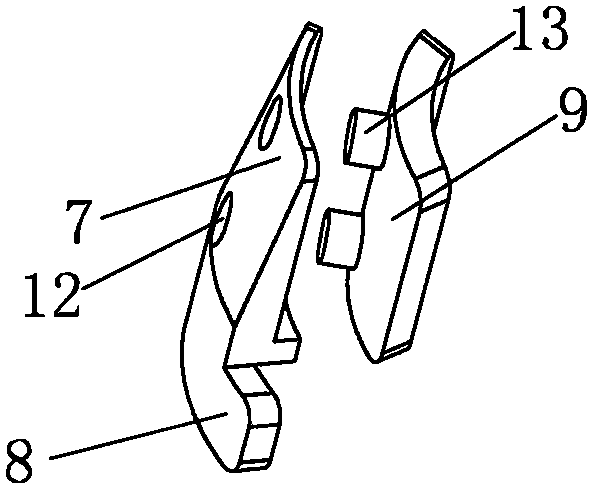

[0038] A clinging mechanism such as Figure 1~6As shown, it includes the main shaft 1, the inner sleeve 2 and the outer sleeve 3. When applied to chairs, the main shaft 1 is also called an air rod. The inner and outer are relative. In the present invention, the inner sleeve is not completely Set in the outer sleeve, only the upper end of the inner sleeve is inserted in the outer sleeve; the inner sleeve 2 and the outer sleeve 3 are made of nylon material, and the upper end of the inner sleeve 2 is provided with a plurality of axially arranged The groove 4 forms a plurality of elastically deformable fins 5 distributed in the circumferential direction, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com