Lining plate structure of ore grinding machine and assembling method of lining plate structure

A technology of ore grinding machine and liner, which is applied in the field of structure and assembly of the liner of the ore mill, which can solve the problems of increasing the cost of grinding, delaying production, affecting the grinding efficiency of the ball mill, etc., and achieves protection from damage and stability Sex, the effect of reducing the relative misalignment phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

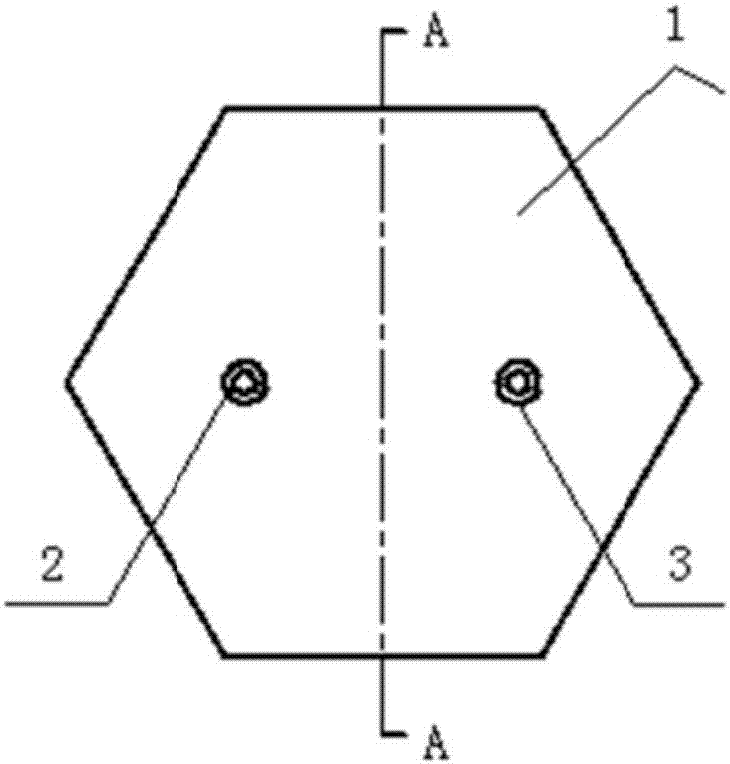

[0025] A mill liner structure (see figure 1 ), it includes a liner main body 1, the shape of the liner main body 1 is a regular hexagon, the liner main body 1 is provided with a first screw hole 2 and a second screw hole 3, the first screw hole 2 and the second screw hole 3 have the same size, the first screw hole 2 and the second screw hole 3 are on the diagonal of the regular hexagon, and the first screw hole 2 and the second screw hole 3 are arranged symmetrically along the center of the regular hexagon.

[0026] In order to ensure the close contact between the liner main body 1 and the cylinder body, the liner main body 1 adopts an arc surface structure.

[0027] In order to facilitate the installation of the liner main body 1 and protect the connecting bolts of the cylinder of the liner, the first screw hole 2 and the second screw hole 3 are countersunk screw holes.

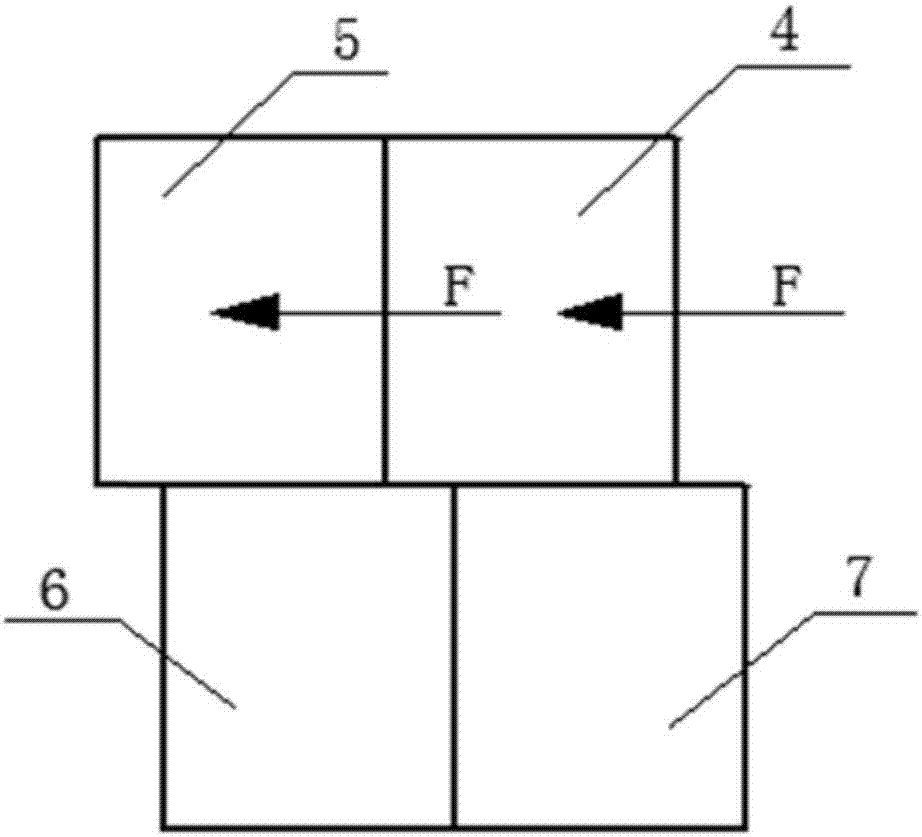

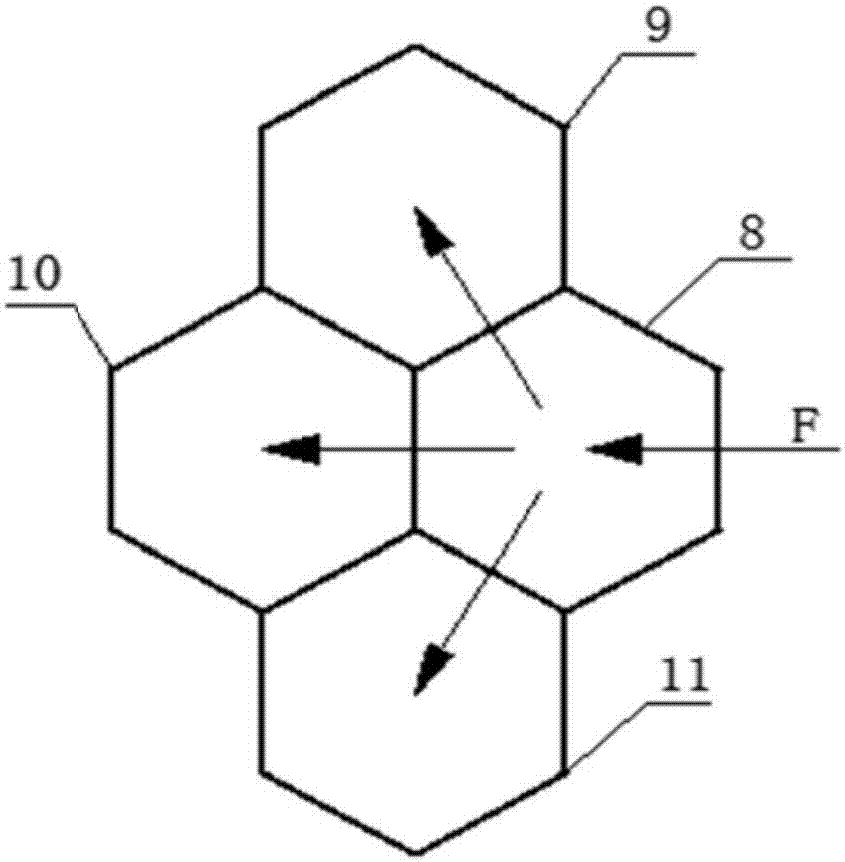

[0028] Such as figure 2 As shown, the force schematic diagram of the rectangular liner in the prior ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com