Adjustable three-dimensional wound core transformer winding machine

A three-dimensional wound iron core and transformer technology, which is used in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of laborious and complicated installation procedures, and achieve simplified installation procedures, easy and reliable adjustment, and simple procedures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

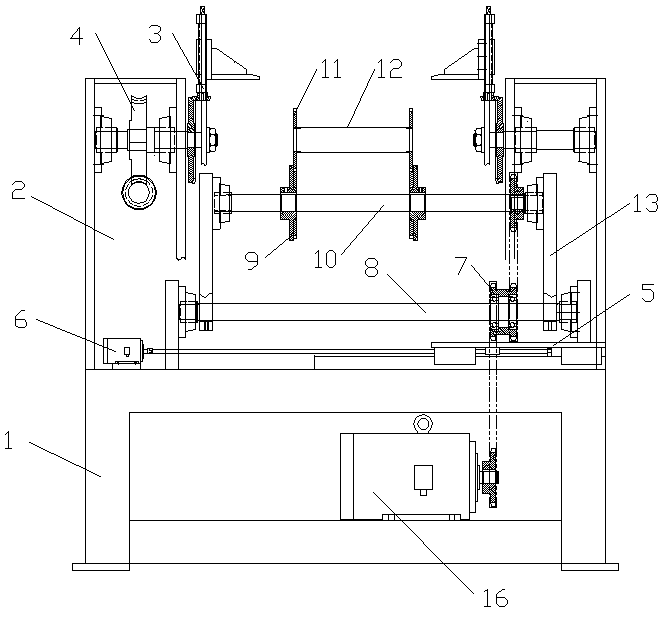

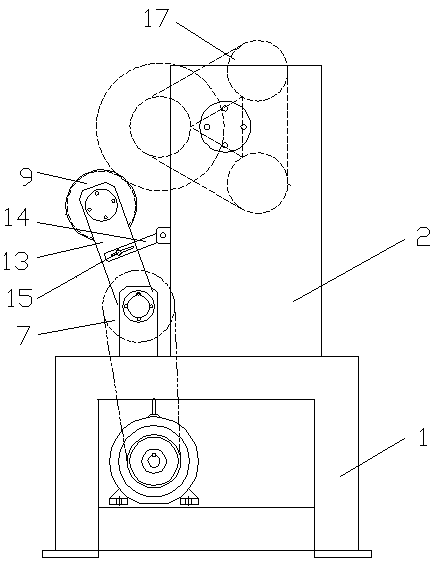

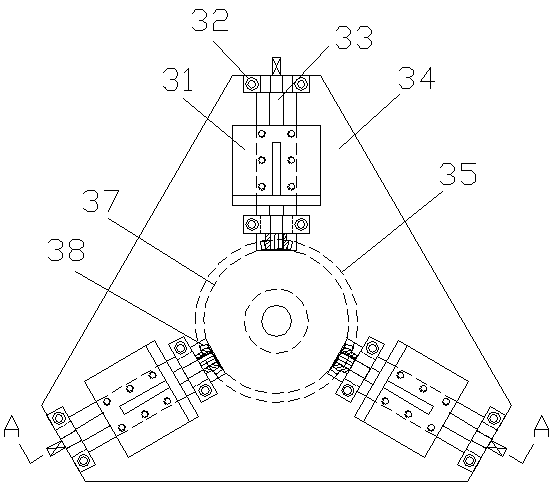

[0022] Such as Figure 1 to Figure 7 The illustrated adjustable three-dimensional wound core transformer winding machine includes a base 1, two ends above the base 1 are symmetrically provided with a bracket 2, and the opposite surfaces of the bracket 2 are respectively provided with three jaws for synchronous clamping. The chuck 3, the bracket 2 is provided with a turbine group 4 for driving the three-jaw chuck 3; the bracket 2 at the upper end of the base 1 is provided with a sliding table 5 at the lower end, and the bracket 2 at the other end above the base 1 is provided There is a motor I6 driving the sliding table 5, and a lead screw transmission device is arranged between the sliding table 5 and the motor I6; the base 1 is provided with an intermediate wheel shaft 8 at a position parallel to the two ends of the support 2 A main shaft 10 parallel to the intermediate wheel shaft 8 is respectively connected to the two ends of the main shaft through the connecting plate 13. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com