Clamping equipment special for large crankshaft turning eccentric machining

A technology of clamping equipment and car eccentricity, which is applied in metal processing equipment, clamping, clamping devices, etc., can solve the problems that the processing accuracy cannot meet the requirements, increase the production cost of the enterprise, and the workpiece has indentation, etc., to improve the processing accuracy. quality, faster production, and improved precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

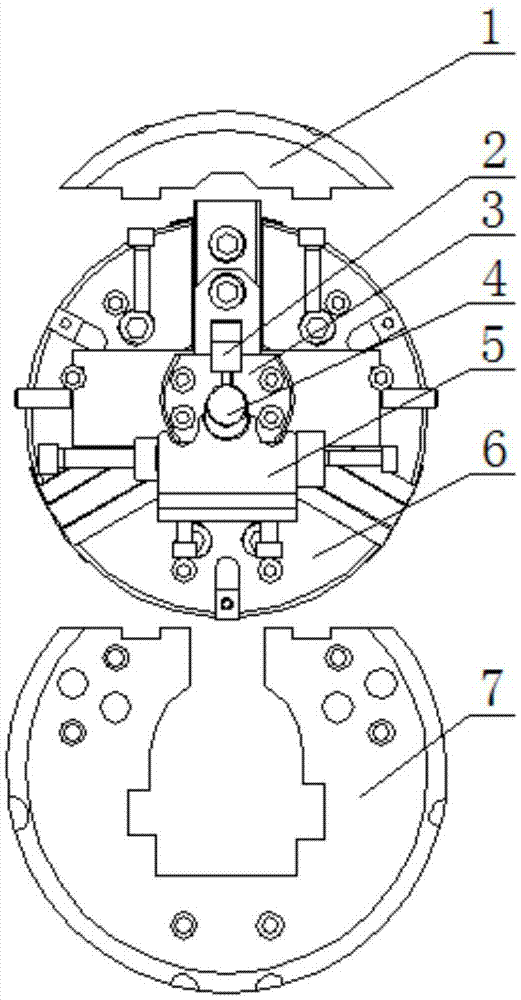

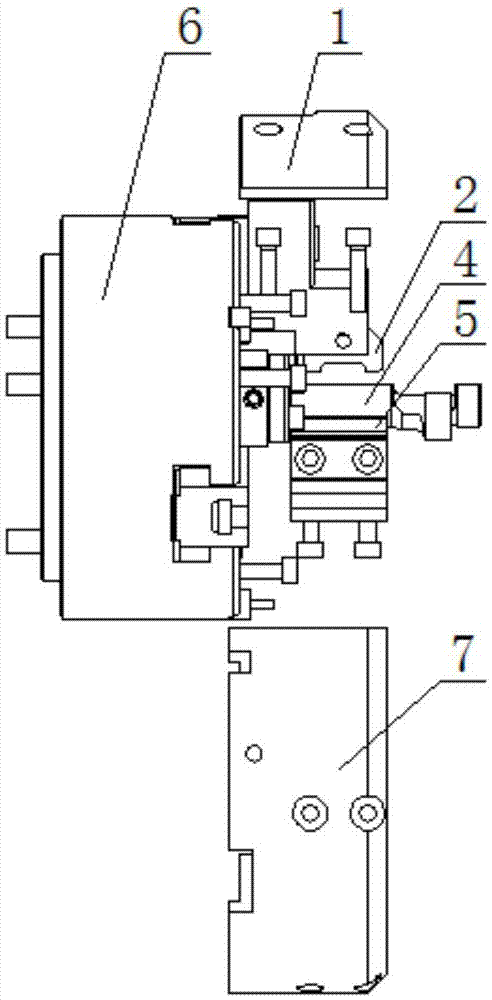

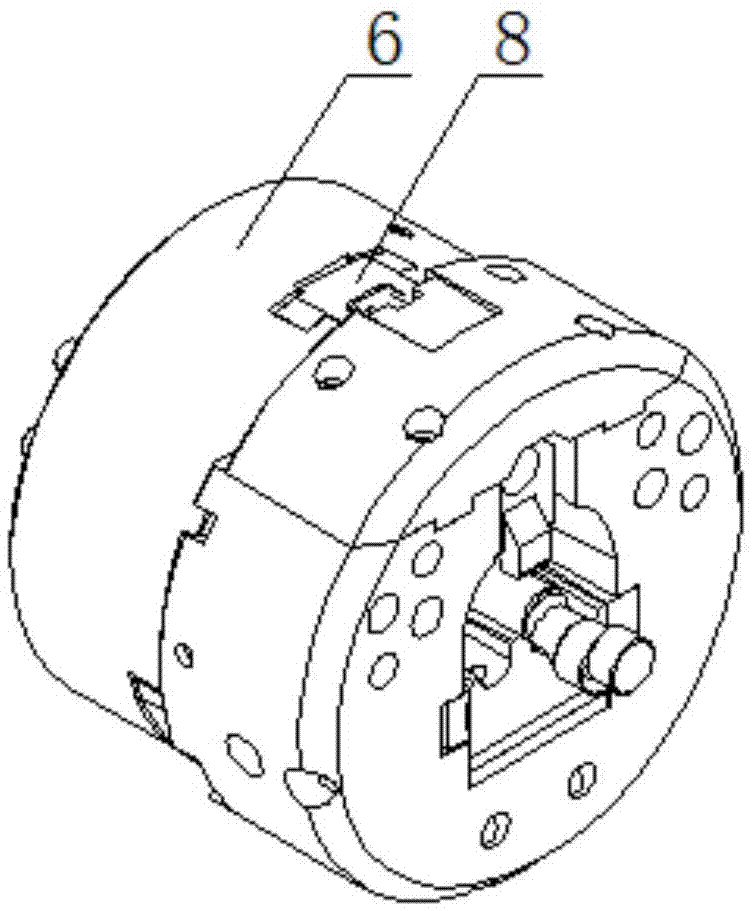

[0019] A special clamping device for large crankshaft vehicle eccentricity, including a clamp body 6, a clamp body connecting plate 1, a clamp body cover 7, a pressure plate 2, a positioning plate 3 and a positioning block 5, the upper part of the front of the clamp body is installed with the clamp body connecting plate, and the clamp The lower part of the front of the main body mounts the clamp main body sleeve.

[0020] Make a slot on the fixture main body cover, a positioning block is installed in this slot, and one or more lower backing plates 9 are installed on the lower bottom surface of this positioning block, so the installation height of the positioning block can be adjusted up and down. One or more sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com