Special transposition type work head for war vehicle action system bolt tightening

A working head and tightening head technology, which is applied in the field of special indexing working heads for bolt tightening of chariot action systems, can solve the problems of flexibility, poor mobility, large space on the assembly site, etc., and achieves high work efficiency and small footprint. , the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

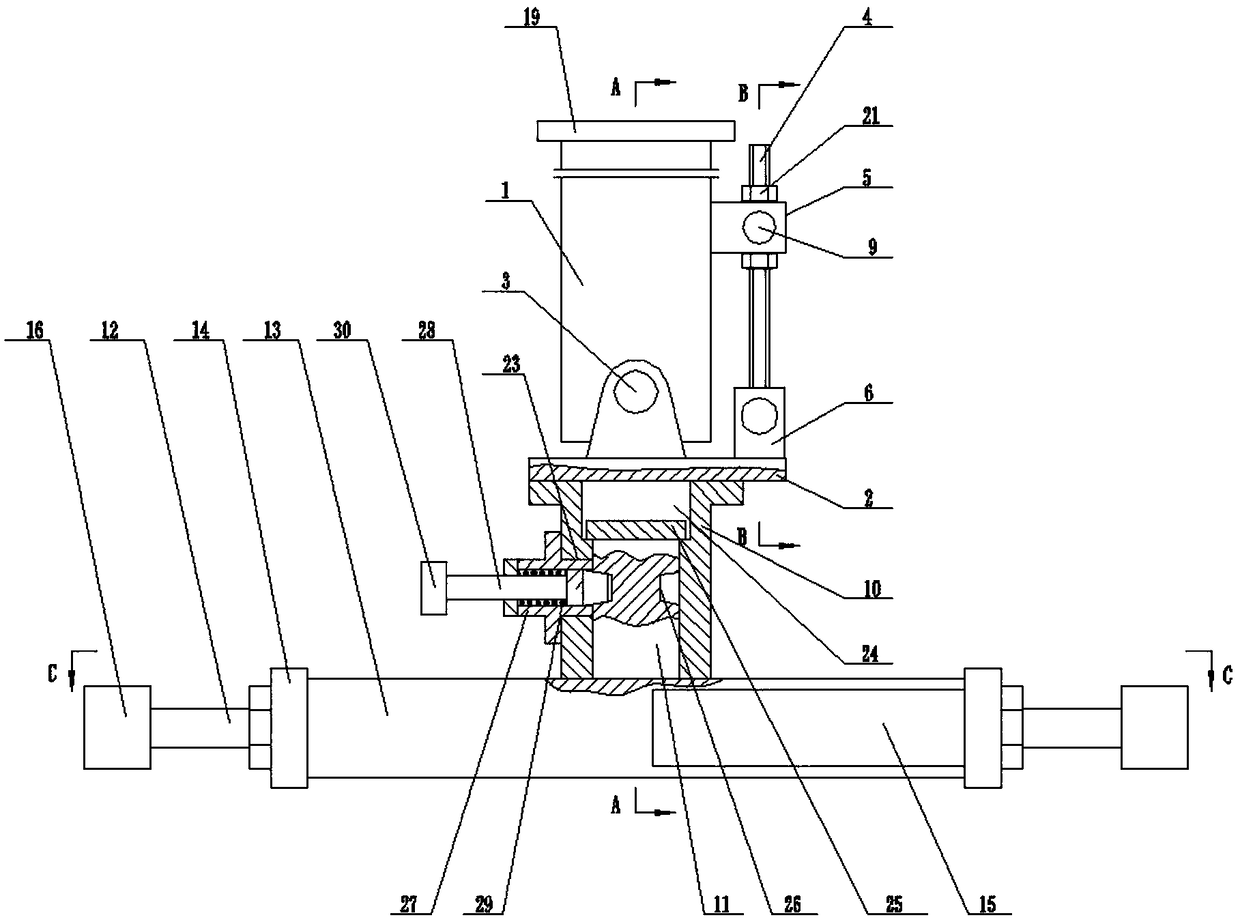

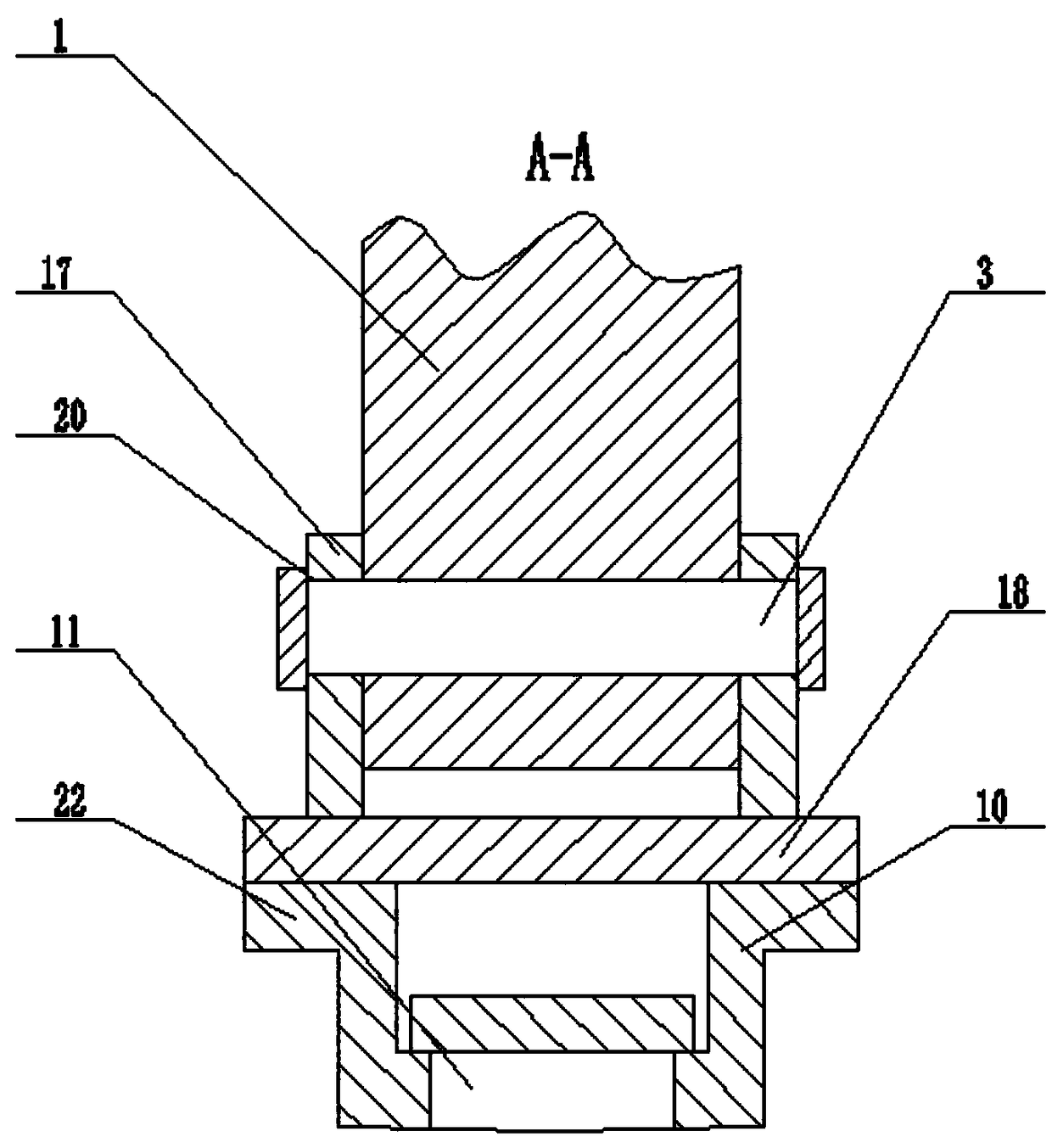

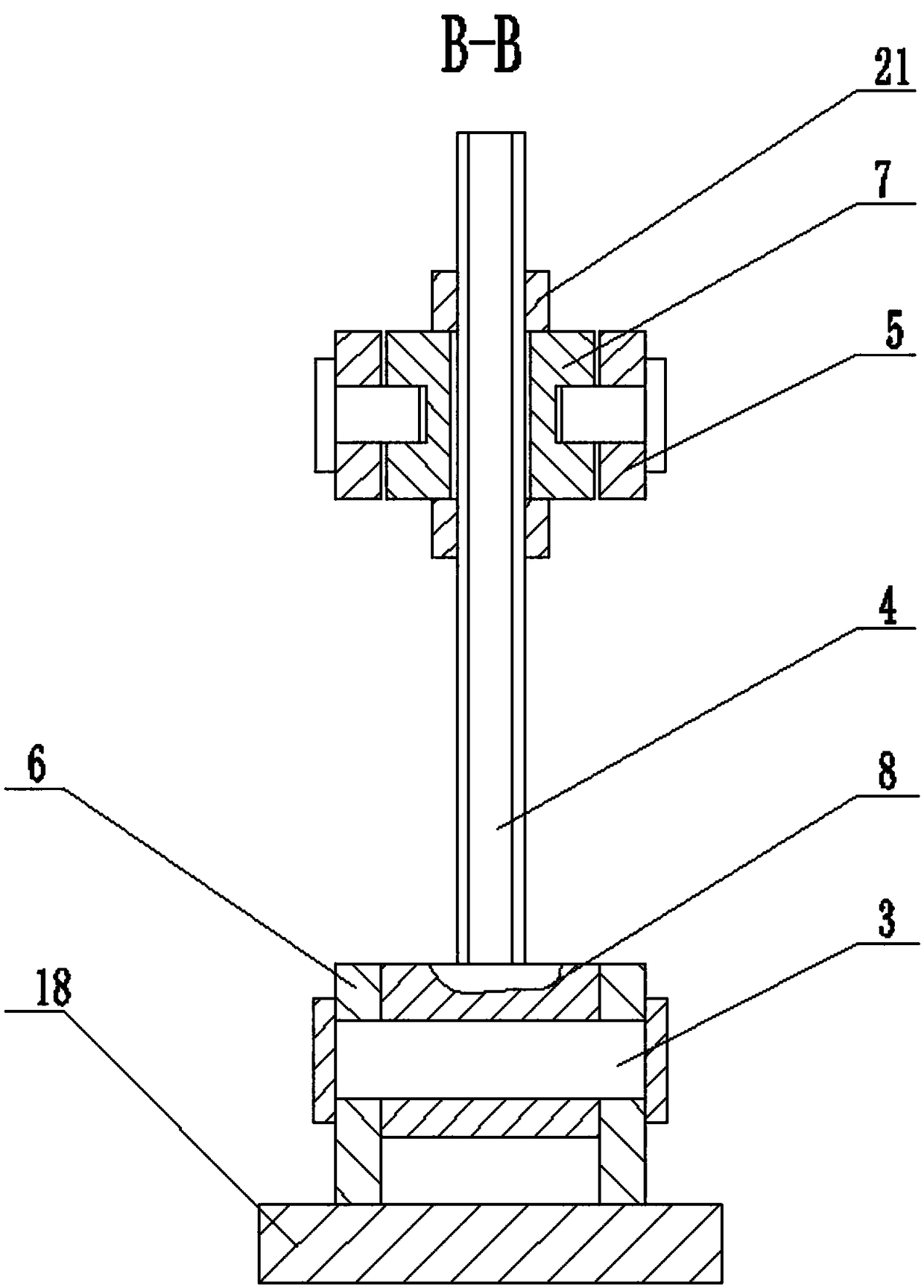

[0023] See attached Figure 1-4 Shown: the present invention provides a special indexable working head for bolt tightening of the chariot action system, which is composed of a connecting arm, an adjusting device, a rotating device and a working head. The connecting arm is connected to the working head through a rotating device, and the connecting The arm is provided with an adjustment device, including a connecting column 1, a connecting seat 2, a hinge shaft 3, a lead screw 4, an adjusting seat 5, a fixed seat 6, an adjusting nut 7, a swing connecting block 8, a mandrel 9, a connecting sleeve 10, Indexing mandrel 11, one-way tightening head 12, rectangular beam 13, wrench support 14, electric torque wrench 15, tightening head 16, connecting ear plate 17, supporting plate 18, connecting flange 19, shaft hole 20, locking Nut 21, fixed flange 22, locking device mounting hole 23, stepped hole 24, annular baffle plate 25, conical blind hole 26, sleeve cup 27, locking pin 28, retur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com