Blender with wheel edge reduction box

A wheel-side deceleration and mixer technology, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of difficulty in achieving rotational freedom compensation, short service life of the reducer, complex structure, etc., and achieves flexible use. , Compensation for structural wear and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

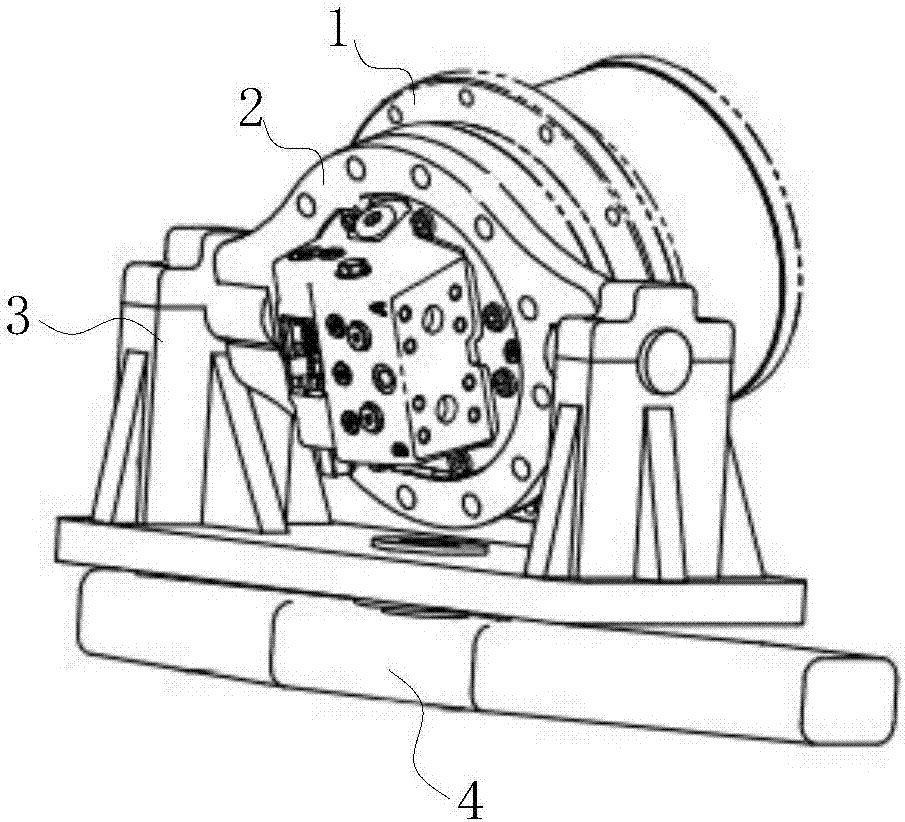

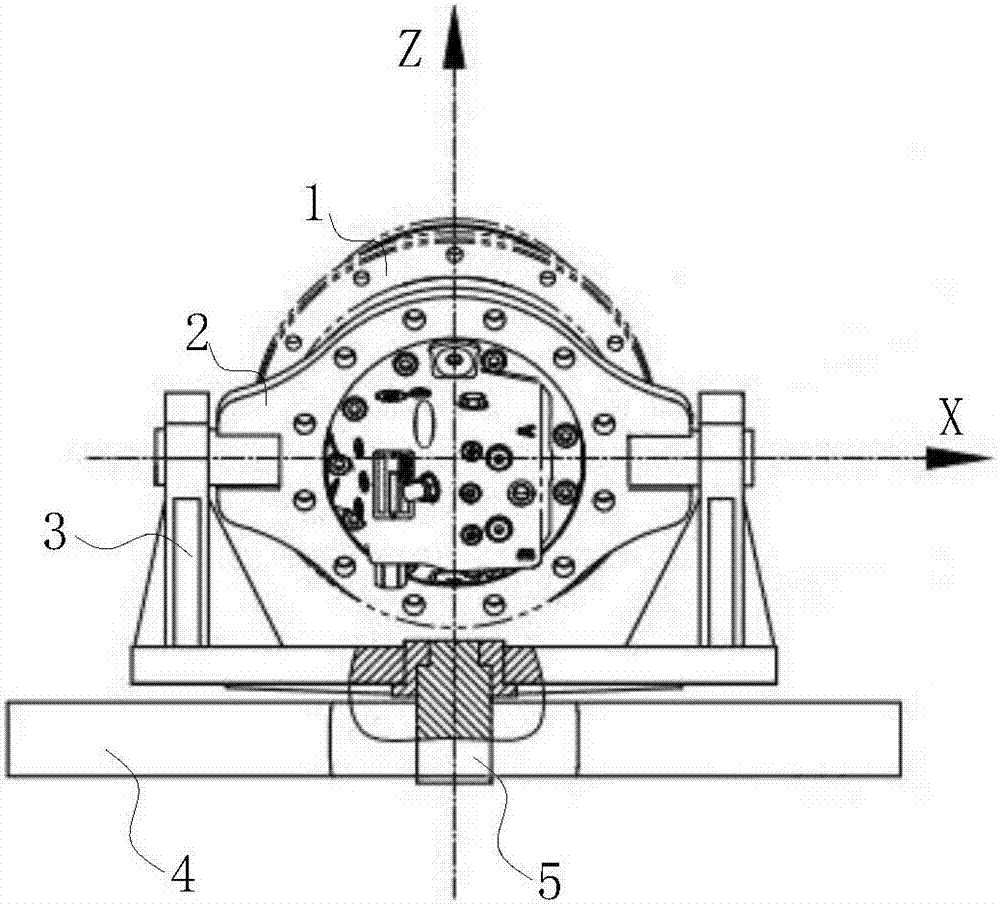

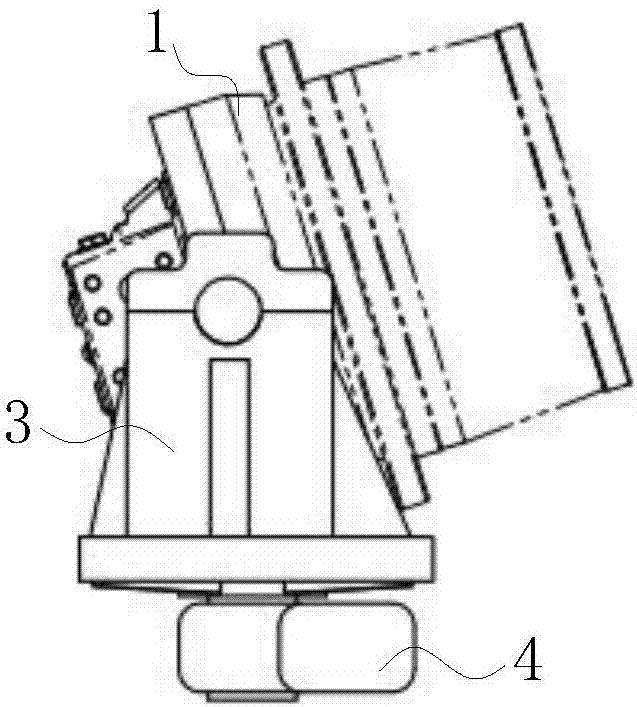

[0018] See attached figure 1 -Attached image 3 , A blender with wheel reducer 1 of the present invention includes:

[0019] Mixing tank;

[0020] The wheel-side reducer 1 is fixedly connected with a flange fixed on the outer end surface of the mixing tank through bolts, and drives the mixing tank to rotate around its own axis;

[0021] A reducer mounting device fixedly connected to the wheel-side reducer 1; the reducer mounting device includes a connecting plate 2 and a base 3. The wheel-side reducer 1 is fixedly connected to the connecting plate 2 by bolts, and the connecting plate 2 Axle pins are welded on both sides, which are connected to the base 3 by the axle pins on both sides; the rotation freedom of the tank body in the X-axis direction is ensured. The installation device not only supports the mixing tank, but also makes the tank The bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com