Method and device for fixing a plastic component to a carrying component

A technology for plastic components, fixtures, applied in the direction of connecting components, transportation and packaging, superstructure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

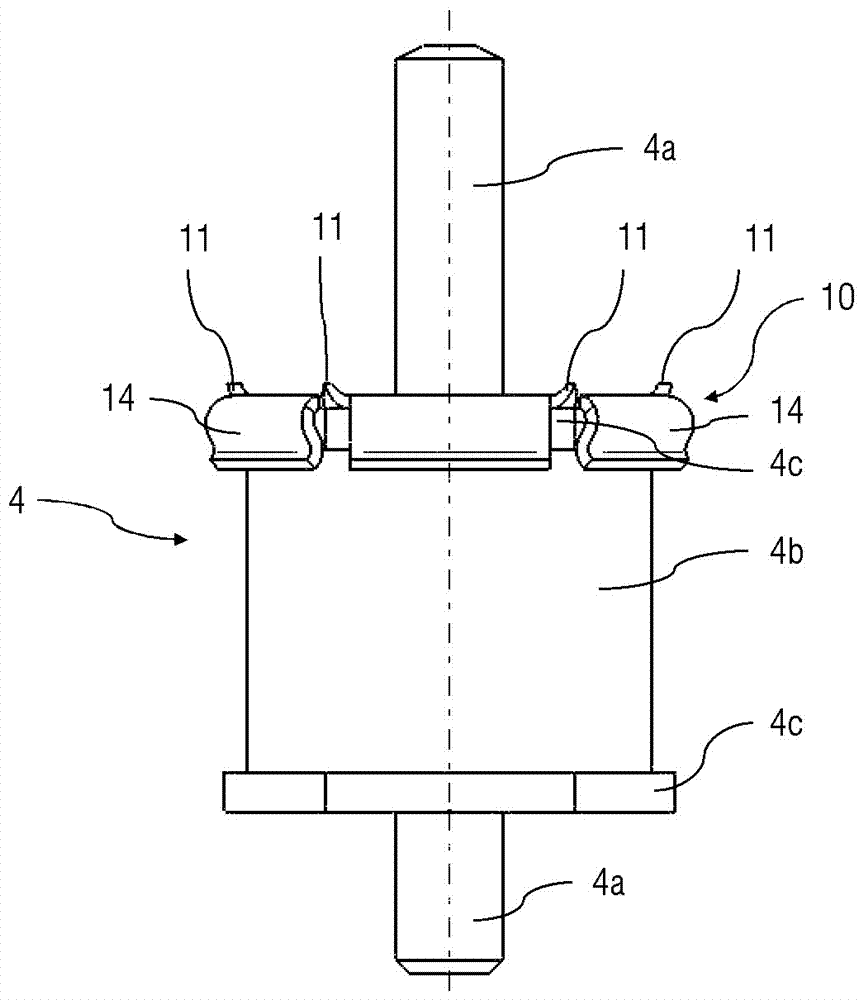

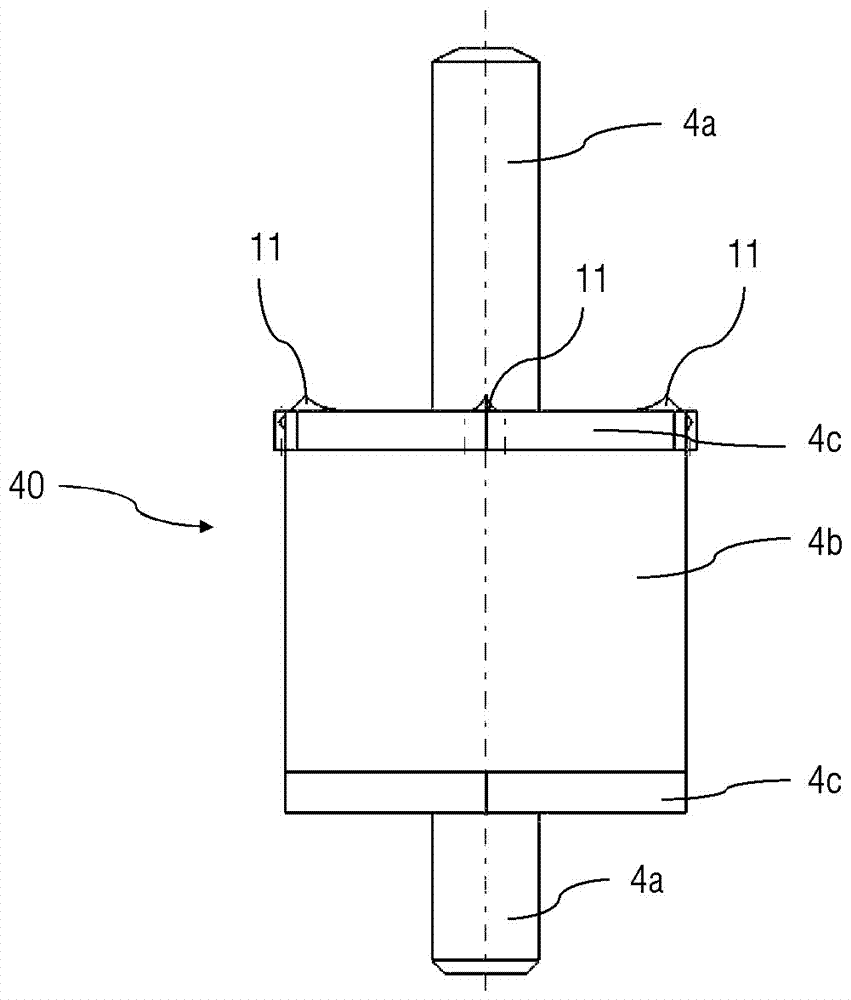

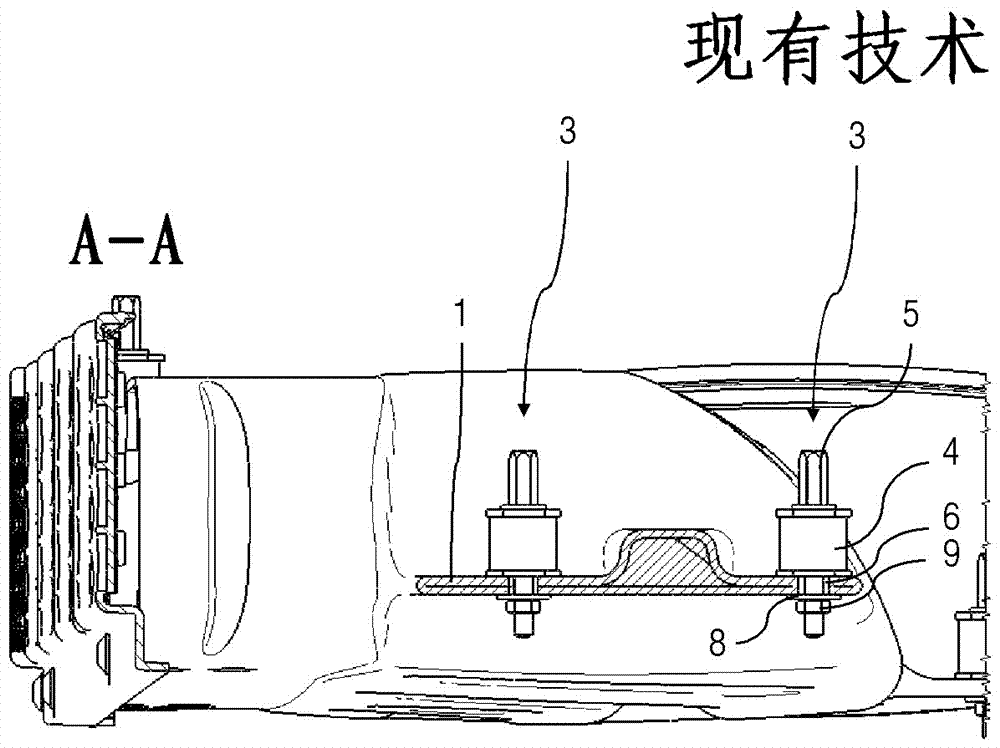

[0029] image 3 A perspective exploded view of a fastening device 15 according to an exemplary embodiment of the invention is shown. The fastening device 15 serves to fasten the plastic component 1 , here the plastic air intake shaft 1 , on the supporting component 2 . In the example shown, the supporting component is the rear cab wall of a commercial vehicle. To this end, the air intake shaft 1 has a tapered section 1 a at its upper end, which has two through-holes 7 . A metal bushing 6 is pressed into each through hole 7 .

[0030] In order to decouple the air intake shaft 1 from the driver's cab in terms of vibration, the air inlet shaft 1 is fastened together with the rubber-metal damper 4 to the rear wall 2 of the driver's cab. The rubber-metal buffers 4 used here are respectively composed of two metal discs 4c and a cylindrical rubber part or rubber body 4b arranged between the two metal discs 4c. The two metal disks 4c are fixedly connected with the rubber piece 4b ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com