A scanning tunneling microscope structure using motor-scanning head separation technology

A separation technology and scanning tunneling technology, applied in the field of scanning tunneling microscope structure, to achieve the effect of clear imaging and preventing thermal drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

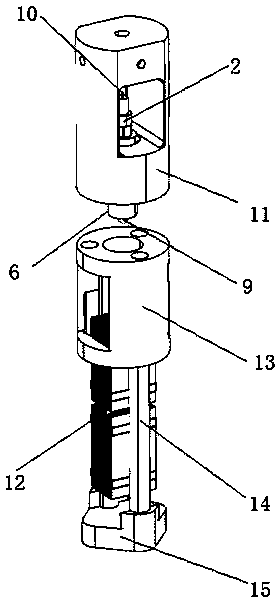

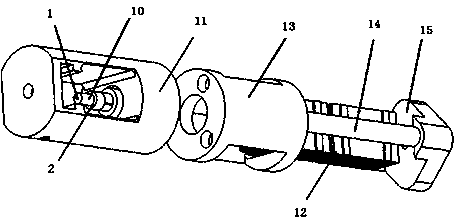

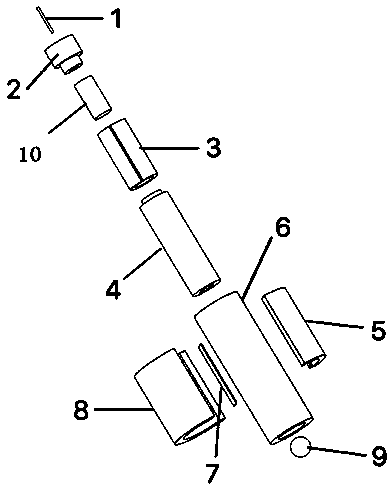

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0019] The invention provides a scanning tunneling microscope structure using motor-scanning head separation technology. The invention improves the existing scanning tunneling microscope to solve the technical problem that the impact of the stepping motor on the scanning head in the existing scanning tunneling microscope leads to the decline in imaging quality. , so that it can effectively prevent thermal drift, electrical fluctuations and other interference factors generated by the motor from affecting the imaging of the scanning head, making the imaging clearer.

[0020] As an embodiment of the present invention, the present invention provides a scanning tunneling microscope structure using motor-scanning head separation technology, including a probe 1, a scanning head, a titanium top seat 11, a piezoelectric stack motor 12, and a scanning tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com