Method for obtaining surface normal vector of automobile workpiece based on point cloud model

A workpiece surface and point cloud model technology, which is applied in the field of calculating the normal vector of the surface of the automobile workpiece, can solve the problems of large calculation amount, slow calculation speed, and low accuracy of the normal vector of the surface, and achieve the effect of reducing the calculation amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Specific implementation mode one: the specific steps of a method for obtaining the surface normal vector of an automobile workpiece based on a point cloud model in this embodiment are as follows:

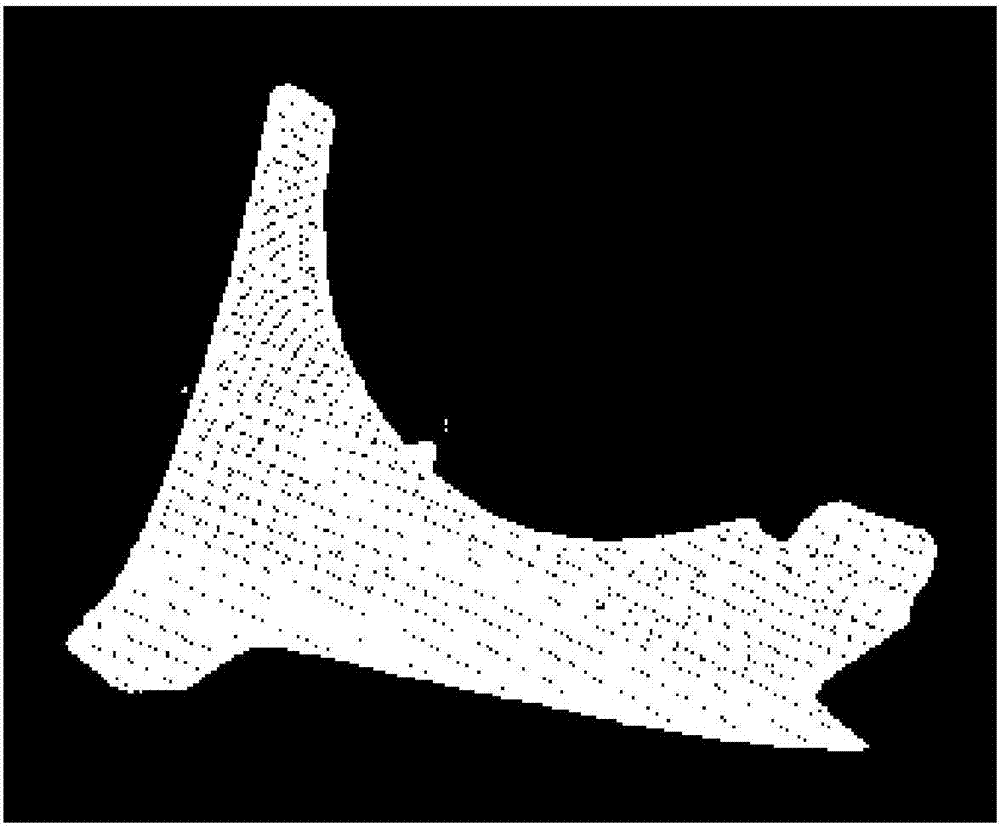

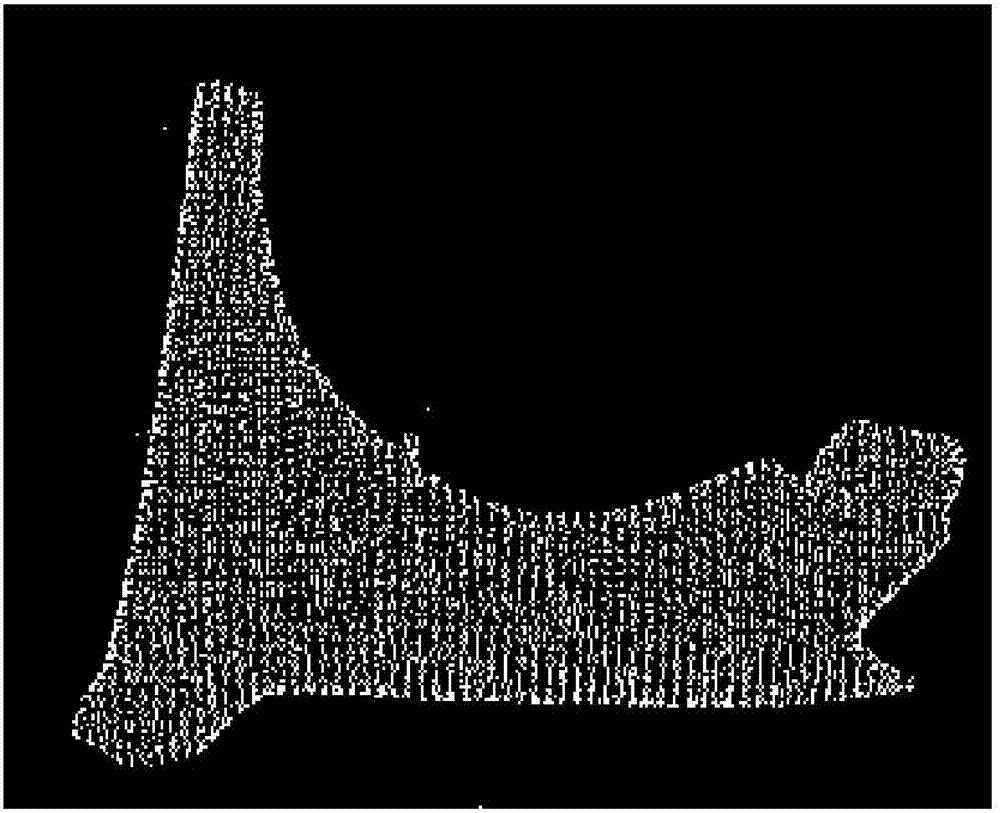

[0018] Step 1. Scan the automobile workpiece to obtain the point cloud image, and use the octree method to compress the point cloud image to obtain the compressed point cloud image; where the automobile workpiece is sprayed is there; figure 1 ;

[0019] Step 2, performing spatial position encoding on the compressed point cloud image obtained in step 1, to obtain the spatial neighbor relationship between points;

[0020] Step 3, using the spatial neighbor relationship between points to obtain the normal vector according to the least square method.

specific Embodiment approach 2

[0021] Specific embodiment two: the difference between this embodiment and specific embodiment one is: scan the automobile workpiece in the step one, obtain the point cloud map, adopt the method of octree to compress the point cloud map, obtain the compressed point cloud map; specifically The process is:

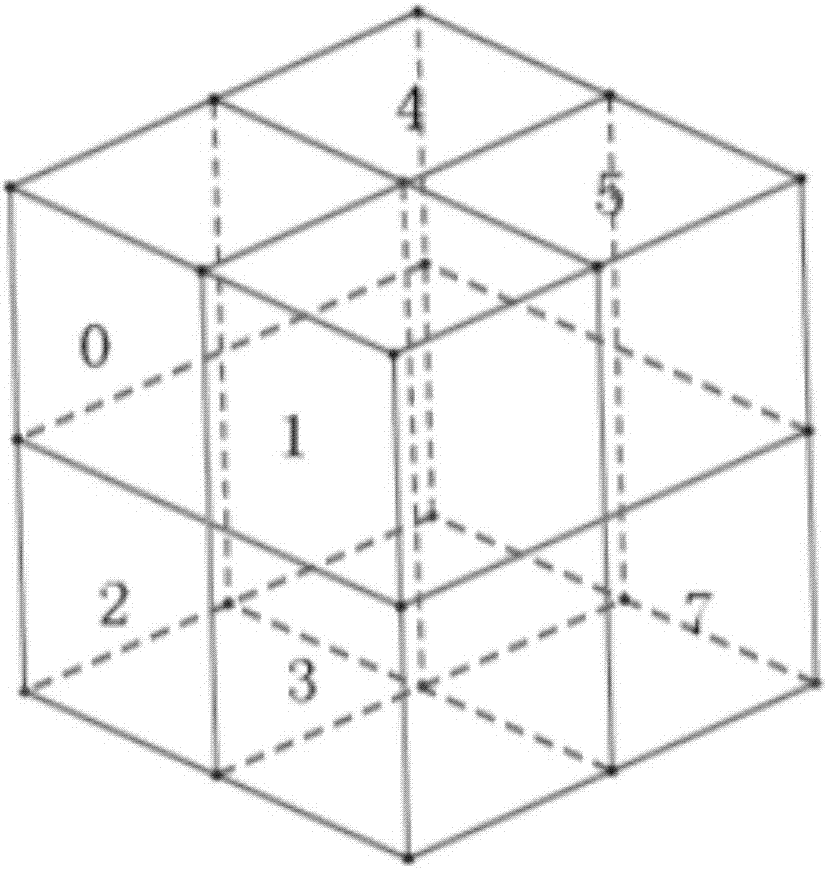

[0022] Step 11, traversing the point cloud data, using the octree algorithm to divide the point cloud data; the specific process is:

[0023] Use a recursive method to divide the obtained point cloud image data. Before dividing, first determine the maximum number of point clouds in each subspace m; the value of m is a positive integer;

[0024] Divide the space where the parent node is located into eight subspaces, and determine the scope of each subspace; assuming that the minimum point coordinates of the space where the parent node is located are (x, y, z) (consistent with the right-hand rule), in the three The lengths on the axis are l x , l y , l z ;

[0025] Then, ...

specific Embodiment approach 3

[0031] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in the step two, the compressed point cloud image obtained in step one is encoded for the spatial position, and the spatial neighbor relationship between points is obtained; The specific process is:

[0032] In order to facilitate the query of K-nearest neighbors, according to the characteristics of the octree structure, the nodes can be encoded in octal, and any node can be associated with octal data; that is:

[0033] Q=q n-1 8 n-1 +q n-2 8 n-2 +…+q 2 8 2 +q 1 8 1 +q 0 8 0

[0034] In the formula, Q is the node number, n is the node depth, that is, the number of space divisions, and q j It is octal data, the value range of j is 0≤j≤n-1; the value of n is a positive integer; in this way, the position information of each subspace in the space is encoded. The access path from the root node to the corresponding leaf node can be obtained from the code. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com