Hot-pressing conversion rigid flat pipe and battery thermal management device

A thermal management and flat tube technology, which is applied in the field of thermal pressure conversion rigid flat tubes and battery thermal management devices, can solve the problems of battery heat transfer lag, low heat dissipation capacity of air-cooled battery cooling system, and high cost, and achieve rapid temperature control effect. , the effect of improving temperature uniformity and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

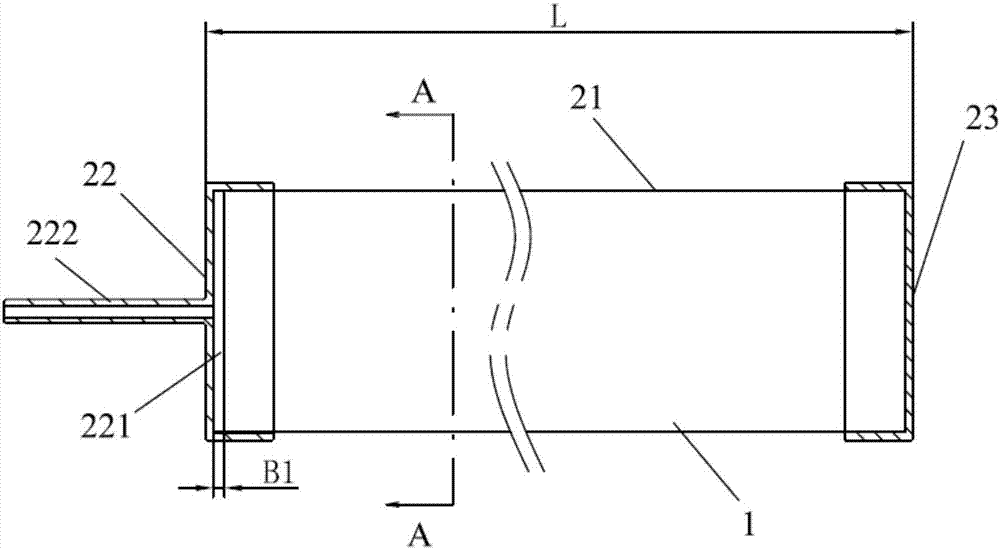

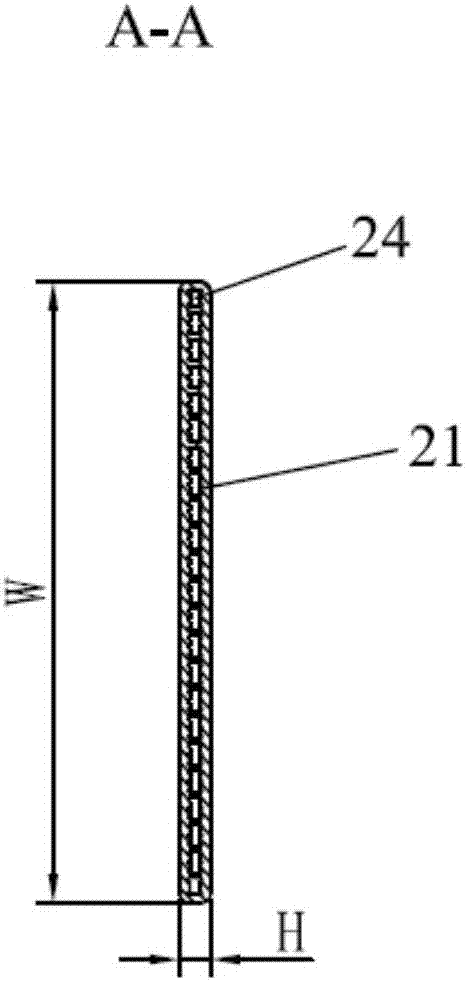

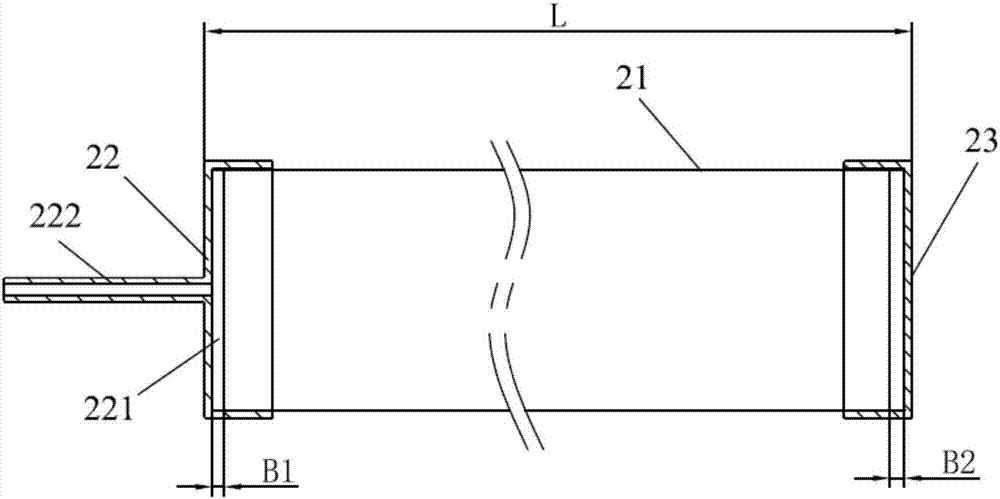

[0036] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0037] The hot-press conversion rigid flat tube 2 adopts the heat transfer effect of hot-press conversion heat transfer, and the utilization principle is as follows:

[0038] Compressible fluid energy transfer equation:

[0039]

[0040] According to the thermodynamic relation, it can be transformed into the following form

[0041]

[0042] where α v is the thermal expansion coefficient, and λ is the thermal conductivity. when α v When it is large, a large pressure change will be generated due to temperature change in the medium, and this pressure change can be u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com