Motor stator core laminating tool

A technology of motor stator and lamination tooling, which is applied in electromechanical devices, manufacturing motor generators, manufacturing stator/rotor bodies, etc., can solve the problems of difficult mold taking, difficult disassembly, poor safety, etc., to avoid personnel injury and facilitate disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

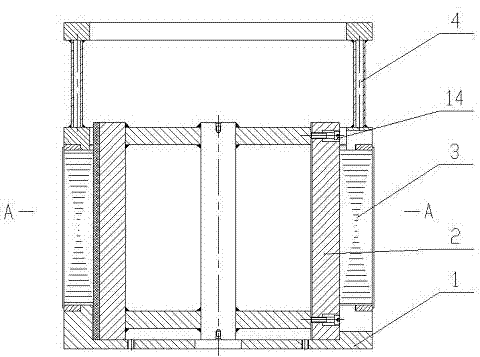

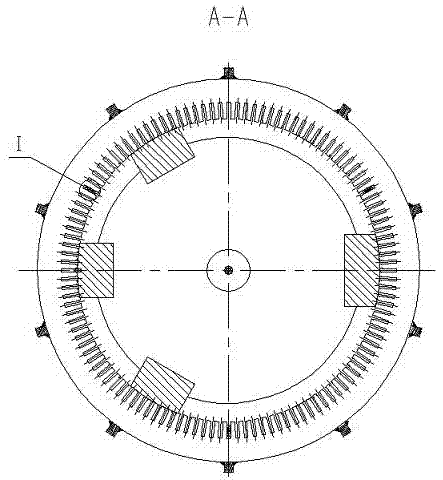

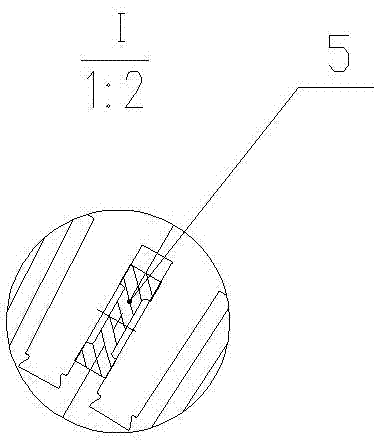

[0016] Such as figure 1 , 2 , 3, 4, 5, and 6, the motor stator core lamination tooling of the present invention mainly includes a base 1, a pressure tire 2, a die 4 and a groove sample block 5; the base 1 is a circular plate with an inner circular hole Seat, on the outer circumference of the base 1, evenly distributed notches are arranged, such as Figure 4 As shown, in order to facilitate positioning welding of the tie bars after the stator core is stacked; the inner diameter of the base 1 matches the outer diameter of the bead 2, and one end of the bead 2 is set in the inner hole of the base 1; the bead 2 It is a cylinder with upper and lower pressure plates 10, and the upper and lower pressure plates 10 are fixed on the cylinder by welding, and a support column 9 is arranged in the center of the press tire 2 along the axial direction, and the upper and lower ends of the support column 9 are fixed on the upper and lower ends. On the pressing plate 10, the upper and lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com