Processing technology of motor core

A processing technology and iron core technology, applied in the field of motor stator and rotor iron core processing technology, can solve the problems of insufficient bonding of punching sheets, failure to meet customers, high temperature requirements, etc., to ensure the lamination coefficient and reduce eddy current loss , Guarantee the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

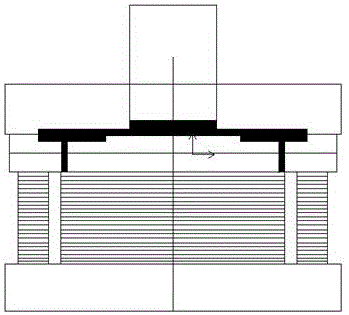

[0015] The present invention is described in further detail now in conjunction with accompanying drawing, and these accompanying drawings all are simplified schematic diagrams, only illustrate the basic structure of the present invention in a schematic manner, therefore, it only shows the composition relevant to the present invention, a kind of motor iron core Processing technology includes:

[0016] Step 1: Check the flatness of the self-adhesive punching sheet, ensure that the flatness is ≤ 1.5 mm, ensure the lamination coefficient of the punching sheet, ensure the flatness of the punching sheet, and ensure the quality of the punching sheet;

[0017] The second step: before bonding, carefully check the surface of the punching film, there should be no oil and dust, and wipe the surface with a clean rag, and the rag should not be stained with alcohol and acetone, so as to avoid uneven outer circles during the bonding process, which will affect the appearance quality of the prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com