Motor rotor and motor

A motor rotor and rotor technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problem of high cost of wind power generators, achieve sufficient demagnetization resistance, cost reduction, and high air gap magnetic flux density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

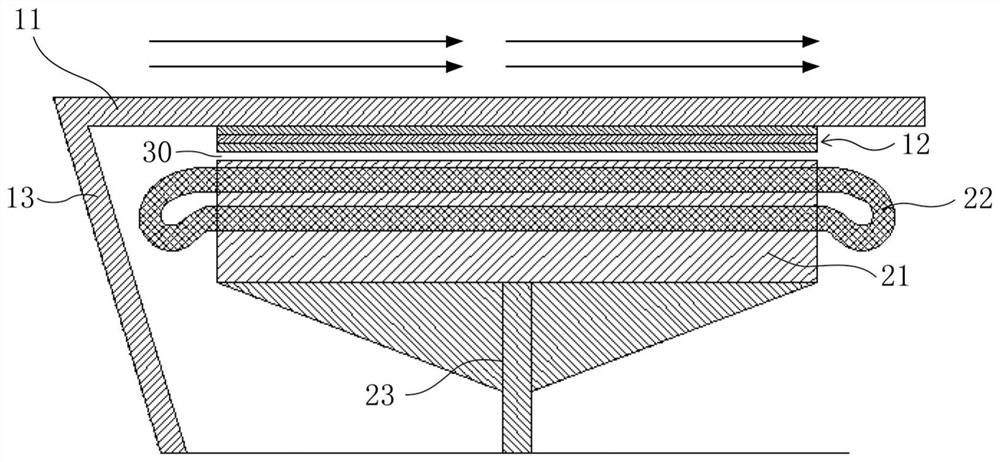

[0026] Embodiments according to the present invention will now be described in detail with reference to the accompanying drawings, examples of which are shown, in which like reference numerals refer to like components throughout. In the following embodiments, a motor with an inner stator and an outer rotor is used as an example to describe the motor rotor and the motor of the present invention, and this description is also applicable to a motor with an outer stator and an inner rotor.

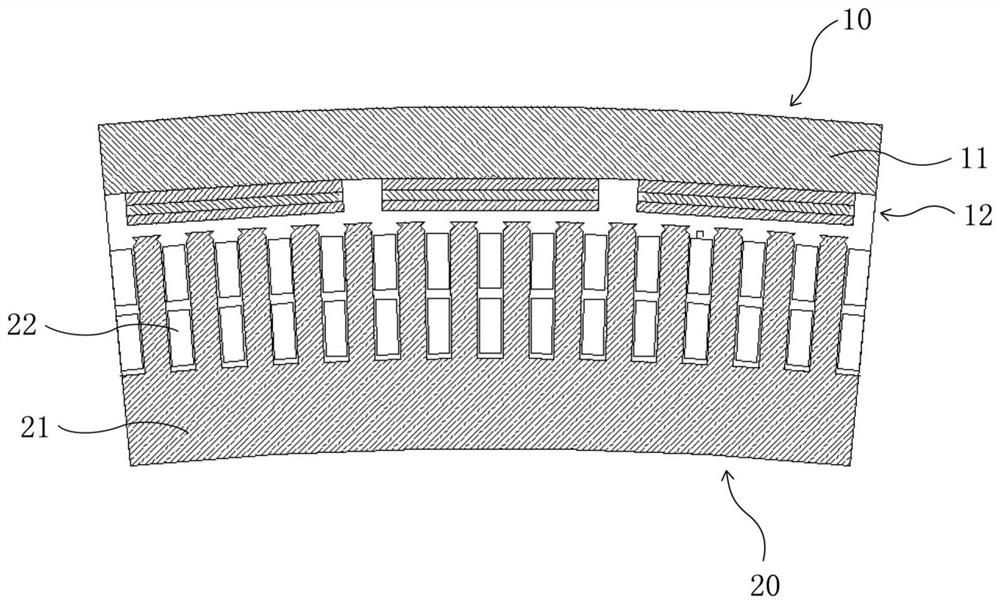

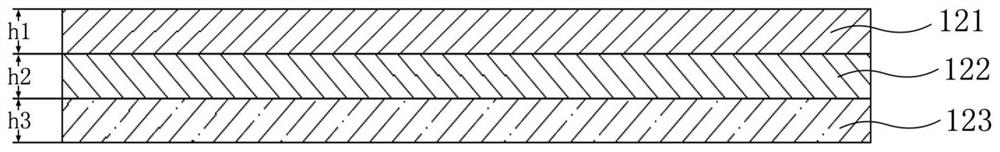

[0027] Such as figure 1 and figure 2 As shown, the motor includes a motor rotor 10 and a motor stator 20. An air gap 30 is formed between the motor rotor 10 and the motor stator 20. The motor can be in the form of an outer rotor with an inner stator, or with an inner rotor with an outer stator. In this application, the outer rotor motor is taken as an example to illustrate the specific implementation of the solution of the application, but it is not limited to the outer rotor motor. Through c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com