Edge safety device for entry and exit pits of cold rolling mill and method of use thereof

A technology of safety devices and potholes, applied in safety devices, roll safety equipment, metal rolling, etc., can solve the problems of high risk of safety accidents, heavy cover plates, frequent operations, etc., to ensure the safety of personnel and the volume of equipment Small, well-controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

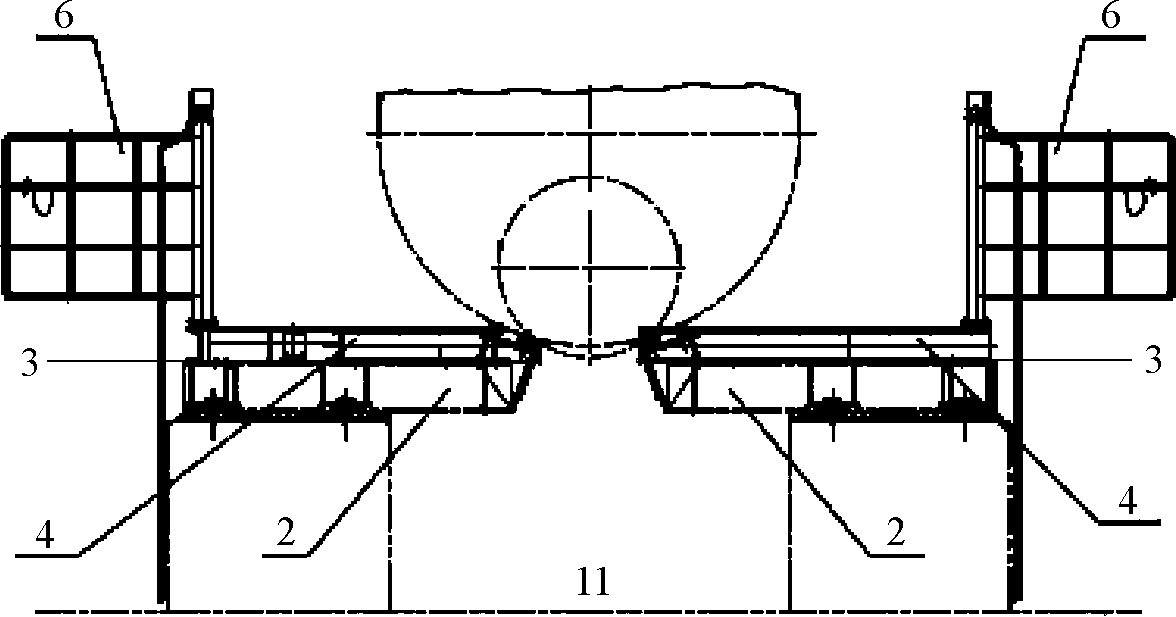

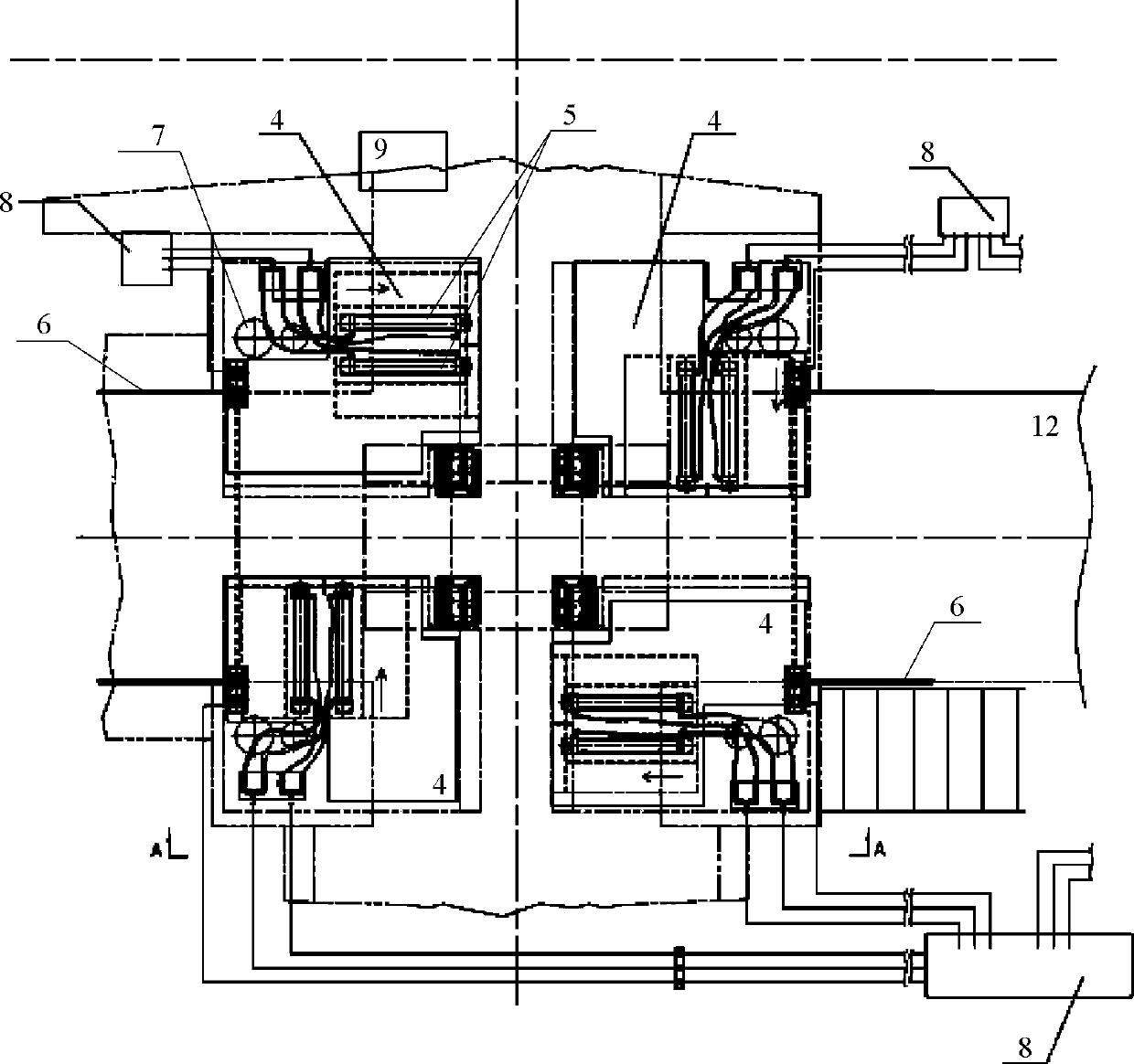

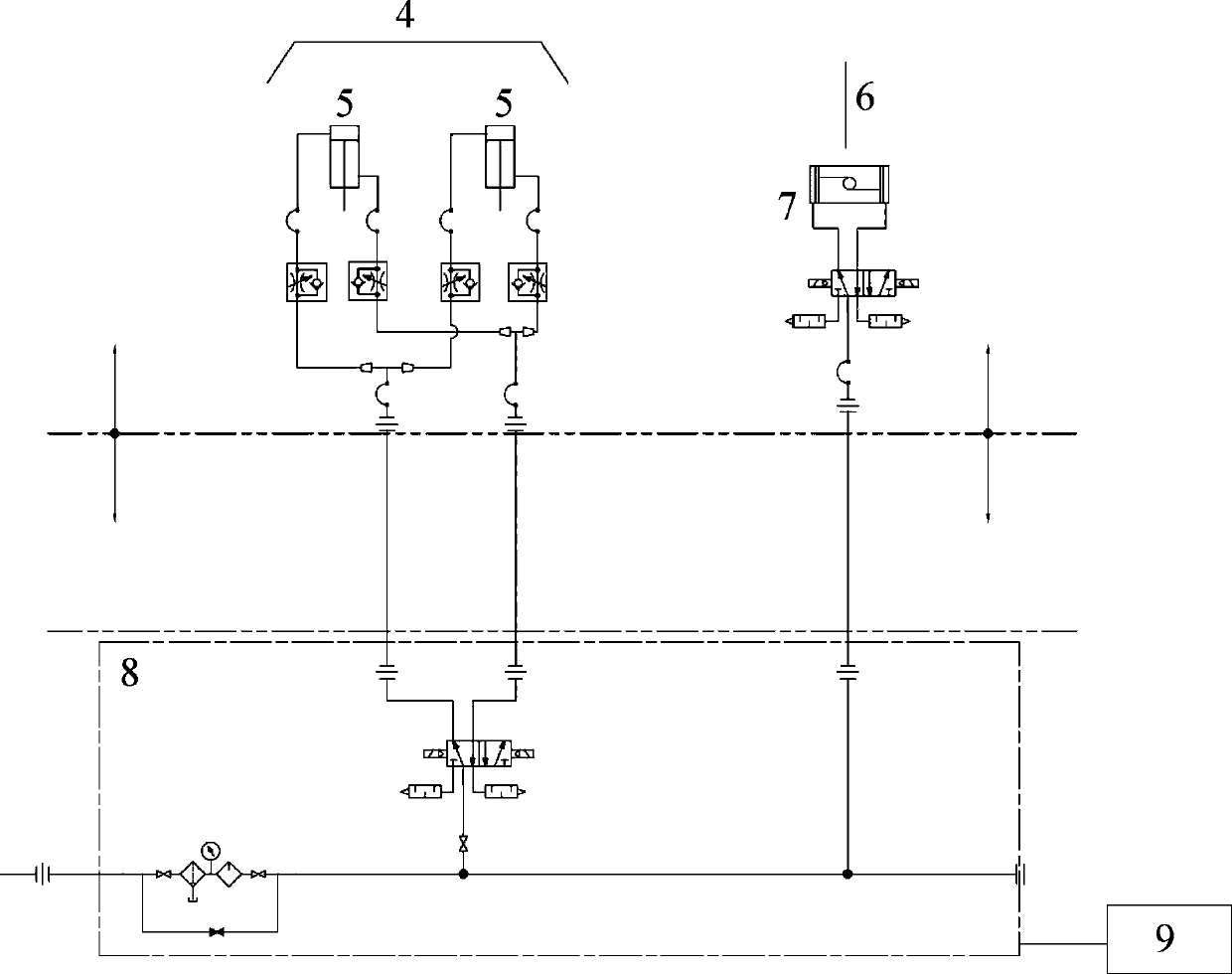

[0024] A side safety device for pits at the entrance and exit of cold rolling mills, including potholes 11, steel coil trolleys 12, saddles 2, guide rails 3, slide plates 4, telescopic cylinders 5, fences 6, rotary cylinders 7, and pneumatic valves station 8 and controller 9, such as Figure 1 ~ Figure 3 As shown, the specific structure is:

[0025] The steel coil trolley 12 is arranged in the pothole 11 and runs along the axis direction of the pothole 11;

[0026] The quantity of saddle 2 is an even number, and saddle 2 is respectively arranged on the both sides of pothole 11 edge, and guide rail 3 is fixed on the saddle 2, and slide plate 4 is arranged on guide rail 3, and each slide plate 4 is connected at least two telescopic cylinders 5 The piston rod and telescopic cylinder 5 drive the slide plate 4 to slide along the guide rail 3;

[0027] The number of fences 6 is an even number, and fences 6 are rotatably arranged on both sides of the edge of pothole 11 respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com