A kind of molybdenum dioxide nano-photothermal conversion material and its preparation method and application

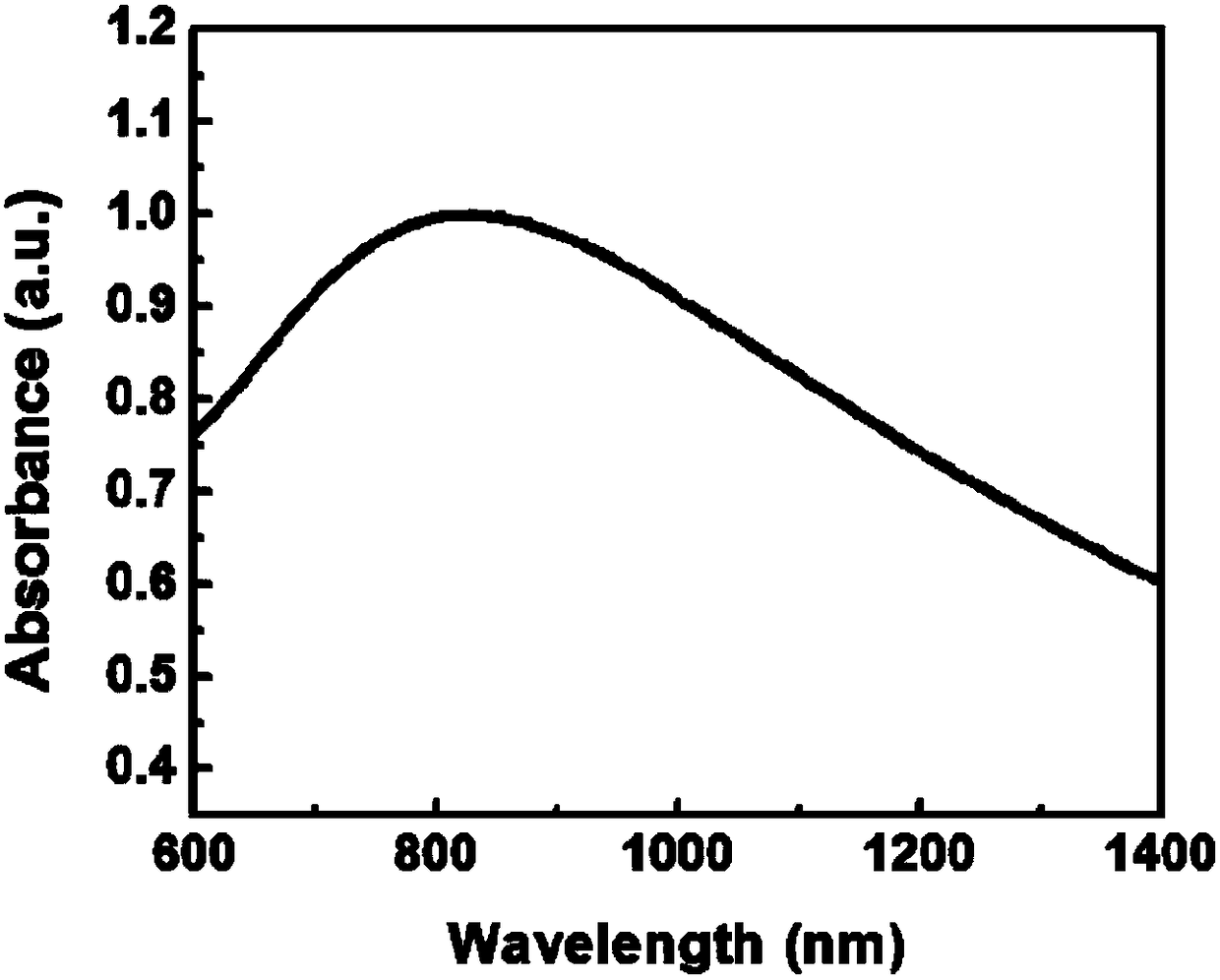

A technology of molybdenum dioxide and nano-materials, applied in the field of molybdenum dioxide nano-photothermal conversion materials and its preparation, can solve the problems of affecting light absorption effect, poor biodegradability, weak near-infrared absorption, etc., and achieve excellent photothermal Stability and biocompatibility, simple and rapid preparation method, effect of tumor size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

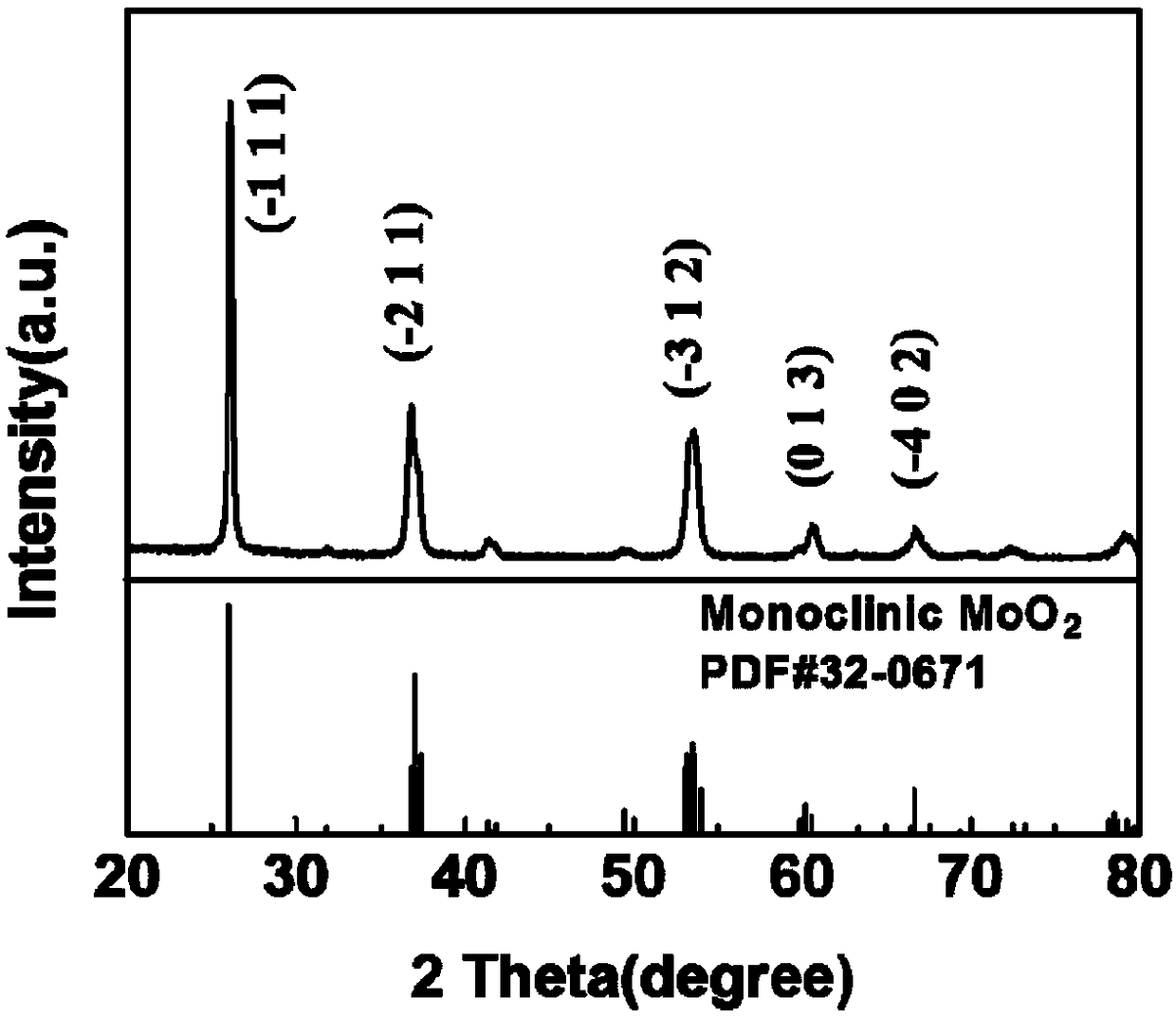

[0040] The combination of liquid phase laser ablation and solvothermal method is used to prepare molybdenum dioxide nano-photothermal conversion materials, which specifically includes the following steps:

[0041] Step 1, preparation of ethanol and H at a volume ratio of 2:1 2 o 2 The mixed solution, the high-purity molybdenum target (99.99%) is immersed in the mixed solution, stirred and mixed evenly;

[0042]Step 2, focusing a laser beam with a wavelength of 1064nm on the surface of simple molybdenum, with a laser pulse frequency of 10Hz, and ablating the molybdenum target for 20min under 250mJ laser energy to obtain a colloid containing molybdenum oxide nanoparticles;

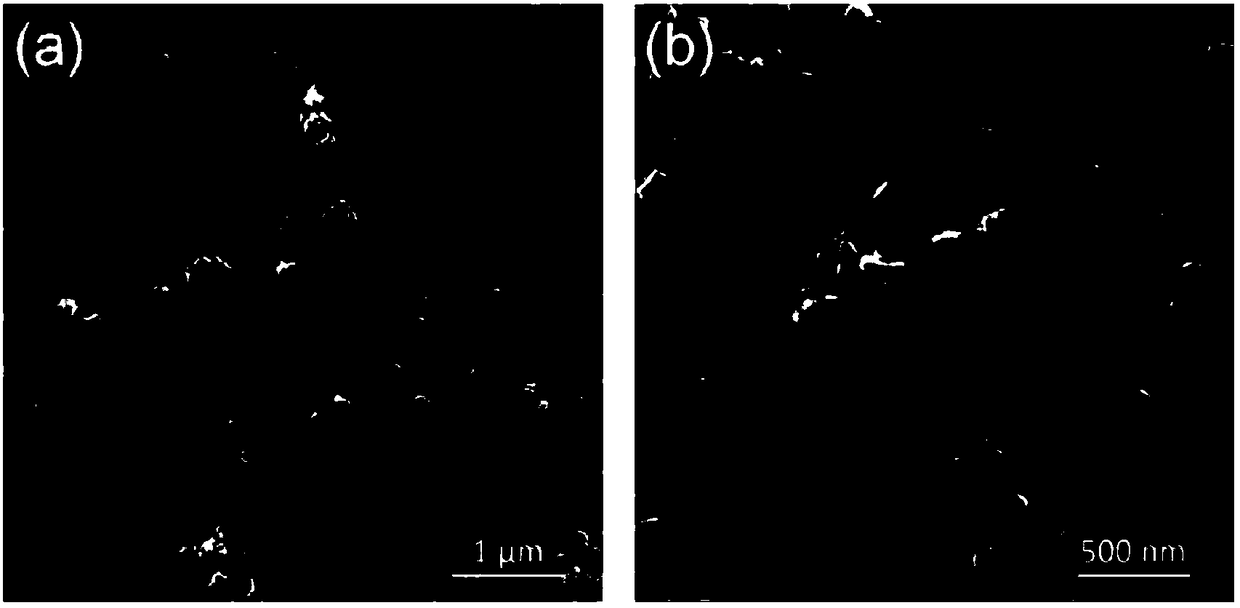

[0043] Step 3. Insulate the colloid containing molybdenum oxide nanoparticles at 180°C for 2 hours, and perform solvothermal synthesis. After the reaction, cool to room temperature, remove the supernatant, and wash and centrifuge the bottom product of the reaction kettle with ethanol for 6 times. 8000r / min...

Embodiment 2

[0049] The combination of liquid phase laser ablation and solvothermal method is used to prepare molybdenum dioxide nano-photothermal conversion materials, which specifically includes the following steps:

[0050] Step 1, preparing ethanol and H at a volume ratio of 1:1 2 o 2 The mixed solution, the high-purity molybdenum target (99.99%) is immersed in the mixed solution, stirred and mixed evenly;

[0051] Step 2, focusing a laser beam with a wavelength of 1064nm on the surface of simple molybdenum, with a laser pulse frequency of 10Hz, and ablating the molybdenum target for 20min under 250mJ laser energy to obtain a colloid containing molybdenum oxide nanoparticles;

[0052] Step 3. Insulate the colloid containing molybdenum oxide nanoparticles at 160°C for 5 hours, and perform solvothermal synthesis. After the reaction, cool to room temperature, remove the supernatant, and wash and centrifuge the bottom product of the reaction kettle with ethanol for 6 times. 8000r / min, ce...

Embodiment 3

[0055] The combination of liquid phase laser ablation and solvothermal method is used to prepare molybdenum dioxide nano-photothermal conversion materials, which specifically includes the following steps:

[0056] Step 1, preparation of ethanol and H at a volume ratio of 2:1 2 o 2 The mixed solution, the high-purity molybdenum target (99.99%) is immersed in the mixed solution, stirred and mixed evenly;

[0057] Step 2, focusing a laser beam with a wavelength of 1064nm on the surface of simple molybdenum, with a laser pulse frequency of 10Hz, and ablating the molybdenum target for 45min under 100mJ laser energy to obtain a colloid containing molybdenum oxide nanoparticles;

[0058] Step 3. Insulate the colloid containing molybdenum oxide nanoparticles at 220°C for 2 hours, and perform solvothermal synthesis. After the reaction, cool to room temperature, remove the supernatant, and wash and centrifuge the bottom product of the reaction kettle with ethanol for 6 times. 8000r / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com