A kind of preparation method of high electron emission rate composite cathode material

A composite cathode, emissivity technology, applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc. The effect of solving high threshold and improving the uniformity of electron emission source density distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

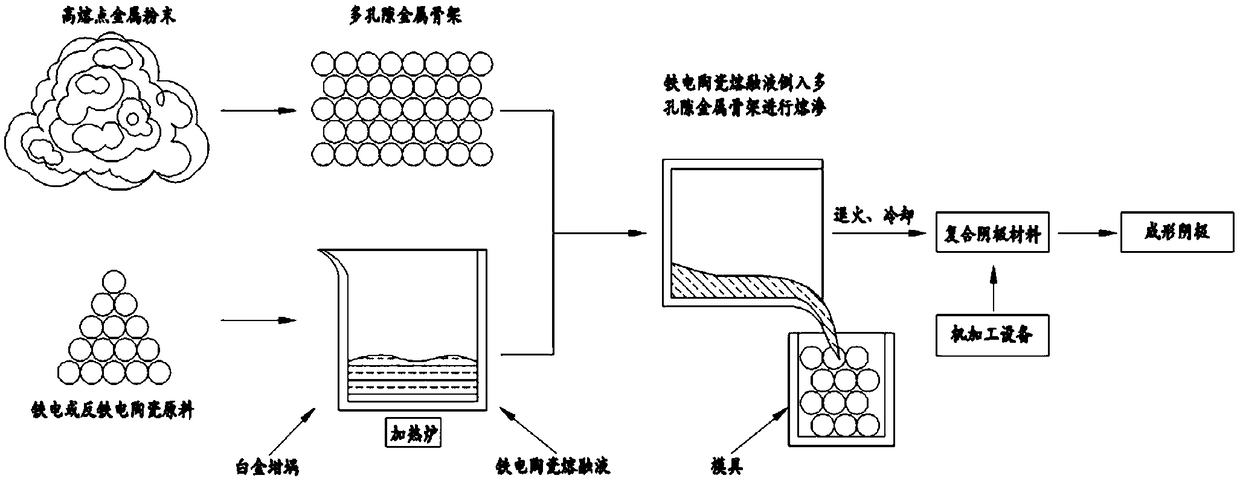

[0024] Such as figure 1 As shown, according to an exemplary embodiment of the present invention, the preparation method of the high electron emission composite cathode material includes the following steps.

[0025] Step A:

[0026] Making a high melting point metal or alloy powder into a porous metal or alloy skeleton with a predetermined shape, grinding ferroelectric or antiferroelectric ceramic materials into powder or mixing raw material powders of said ferroelectric or antiferroelectric ceramic materials uniform.

[0027] Wherein, the refractory metal or alloy powder used in this step can have a melting point or softening temperature higher than the melting point of the ferroelectric or antiferroelectric ceramic material and does not mix with the ferroelectric or antiferroelectric ceramic material melt A metal or alloy that undergoes a chemical reaction. Preferably, it can be tungsten, molybdenum, tantalum, hafnium, chromium, zirconium, titanium, niobium, palladium-iri...

example 1

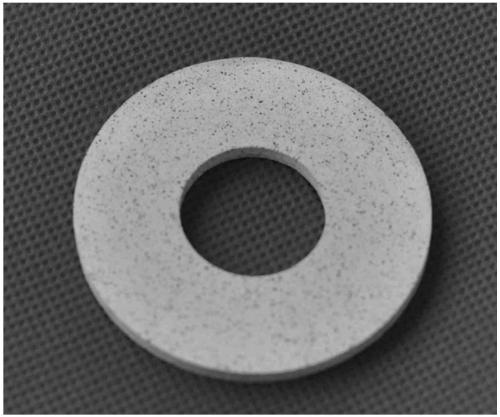

[0040] Example 1: Barium strontium titanate-tungsten composite cathode material

[0041] According to BaCO 3 Powder 40mol%, TiO 2 Powder 27mol%, SrCO 3 Powder 33mol% molar ratio preparation mixture (requires BaCO 3 、TiO 2 , SrCO 3 The purity of the raw materials should be greater than or equal to 99%), ball milled in an alcohol medium for 4 hours, and dried for later use.

[0042] Mix 5% (mass percentage) of tungsten powder, 93% of sodium bicarbonate powder, and 2% polyethylene glycol and press it into a round cake. Microns. Clamp the tungsten-sodium bicarbonate mixture disc between two disk electrodes, apply a high-intensity pulse current to the tungsten-sodium bicarbonate mixture disc, use the electric field activation sintering method to sinter the tungsten particles, and control the current peak at 100A Between ~200A, the pulse width is 5-10 microseconds. During the sintering process, the tungsten-sodium bicarbonate mixture cake should be well cooled so that the te...

example 2

[0046] Example 2: Barium Strontium Niobate-Molybdenum Composite Cathode Material

[0047] According to BaCO 3 Powder, SrCO 3 Powder, Nb 2 o 5 Powder according to Sr 0.5 Ba 0.5 Nb 2 o 6 The molar ratio of the chemical formula is used to prepare the mixture (requires BaCO 3 , SrCO 3 , Nb 2 o 5 The purity of the raw materials should be greater than or equal to 99%), ball milled in alcohol medium for 4 hours, after drying, add a binder with a mass ratio of no more than 2%, mix evenly, put it into a pre-fired mold for compression molding, and the recommended molding pressure is greater than or equal to 50MPa. Then it is sent to a pre-fired furnace and heated to 1500°C for 1 hour, and then naturally cooled to normal temperature.

[0048] Send the pre-fired strontium barium niobate block into the crusher and crush it into a coarse powder with a particle size of no more than 0.1mm. After sieving, add a binder with a mass ratio of no more than 2%, mix evenly, and then put i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com