Rocking sieve

A technology of jacking bolts and positioning springs, which is applied in the field of swinging screens, can solve the problems of easy breakage of pins, short service life, fatigue of rubber parts, etc., and achieve the effect of reasonable jacking structure, long service life and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Embodiments are described in detail in conjunction with the accompanying drawings,

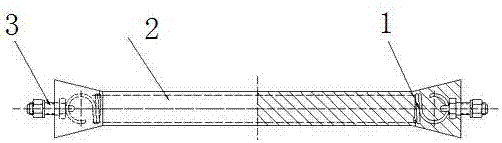

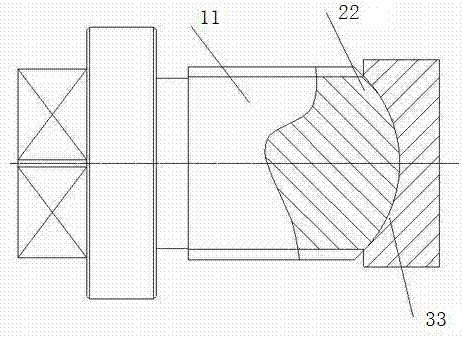

[0009] A special spring for a swing screen, which includes a positioning spring 1, which includes a tightening bolt body, a metal extension spring 2 is set in the positioning spring, and the two ends of the metal extension spring are fixed on the embedded bolt 3; the tightening bolt body 11 The end is hemispherical 22, and the shape of the concave pad 33 matched with the tightening bolt body is: a concave spherical surface with the same diameter as the hemisphere.

[0010] The positioning spring of the present invention, that is, a tension spring is set inside the rubber spring, and the two ends of the tension spring are fixed on the pre-embedded bolts, which is convenient for the installation of the whole special spring; For the pilling surface, the concave pad is a concave spherical surface with the same diameter as the convex spherical surface. Whether the bolt is tightened vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com