Stamping die slanted blanking device capable of being replaced rapidly

A stamping die and oblique punching technology, which is applied in the field of oblique punching devices, can solve the problems of labor-intensive replacement, labor-intensive time-consuming, punch wear and other problems, and achieve the effect of improving efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

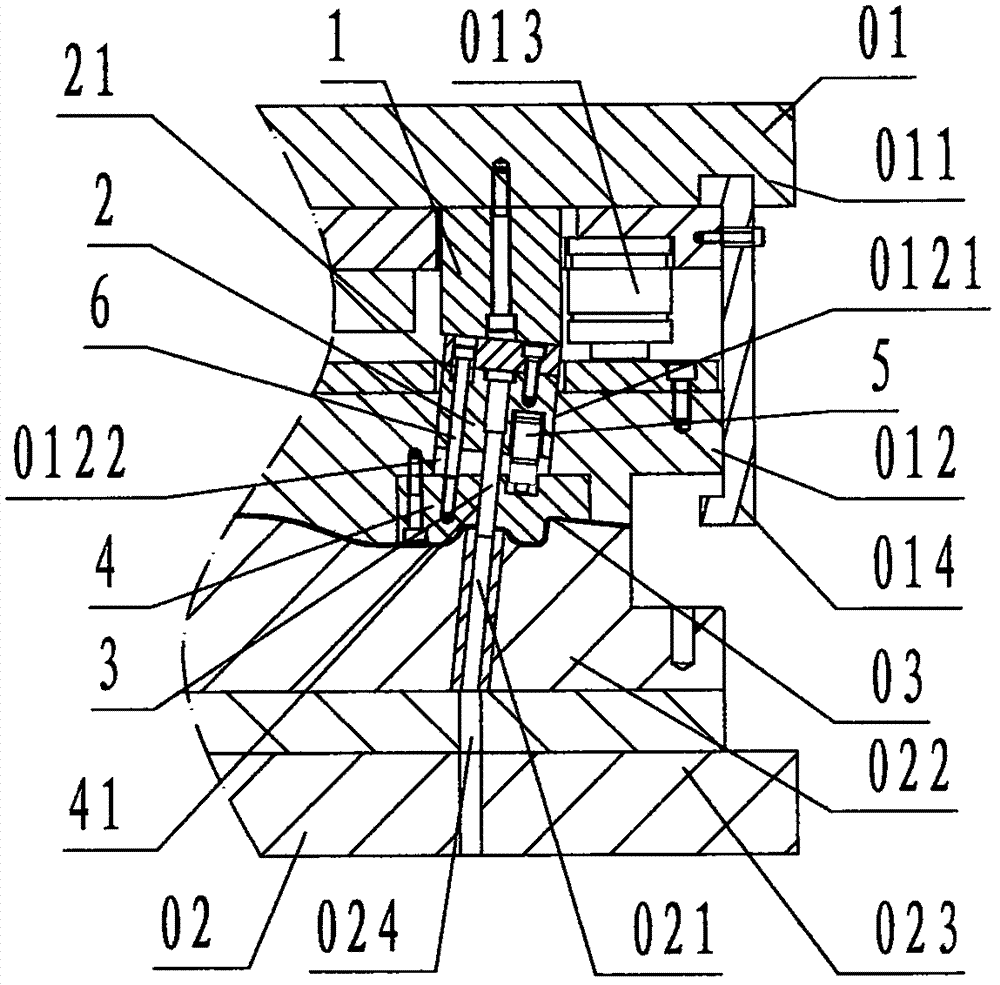

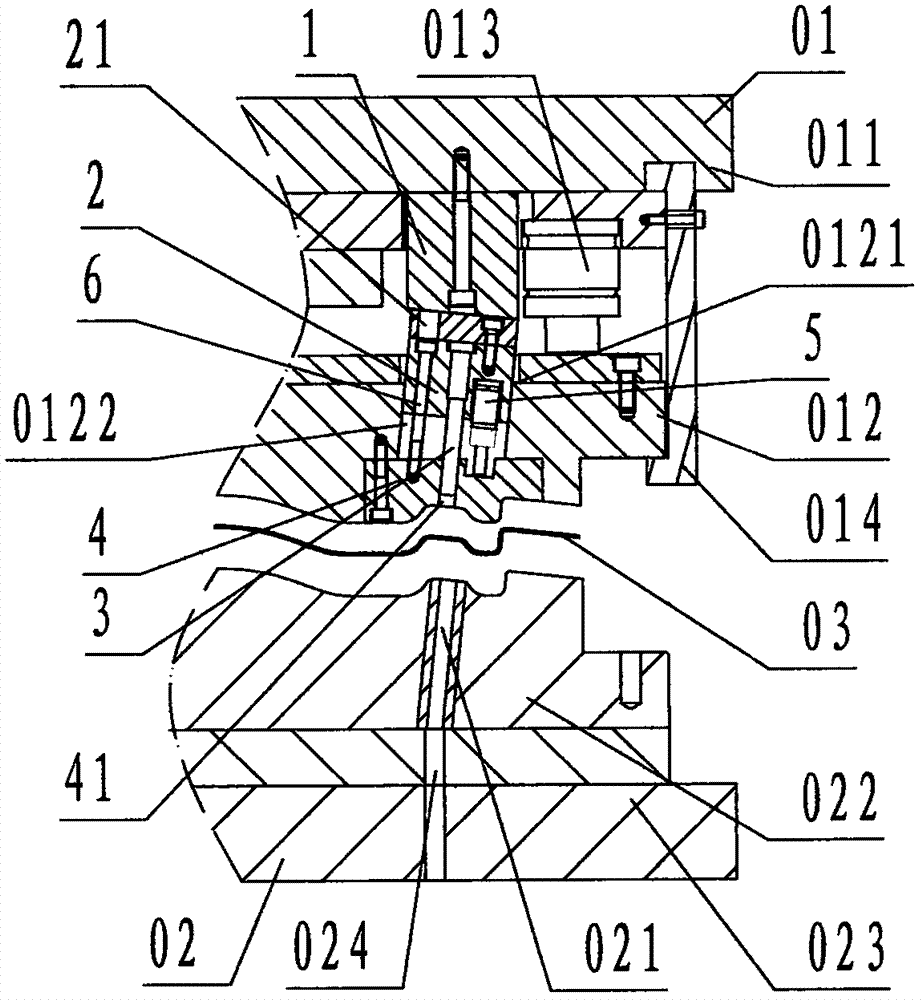

[0023] refer to Figure 1 ~ Figure 2 , a rapidly replaceable stamping die oblique punching device of the present invention, comprising a stamping block 1, a punch carrier block 2, a punch 3, a punch guide block 4, a punch spring 5, a limit bolt 6 and a binder plate 012, wherein: the stamping block 1 is a rectangular block-shaped steel member in a top view, the bottom of the stamping block 1 is provided with a slope inclined from left to right, which is called a stamping slope, and the center of the bottom of the stamping block 1 is provided with The circular step through hole in the up and down direction, small up and big down is called the counterbore of the pressing block;

[0024] The punch 3 is a cylindrical rod-shaped steel component;

[0025] The punch block 2 is a rectangular block-shaped steel member, and the punch 3 is coincidently connected with the central axis of the punch block 2 along the up and down direction, wherein the upper part of the punch 3 is fixed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com