Maintenance-liable elastic cushion damping ballast bed

An elastic pad, easy maintenance technology, applied in the direction of roads, tracks, buildings, etc., can solve the problems of promotion and application, many impurities in water, discount of vibration reduction effect, etc., to achieve the effect of broad market application prospects, high cost performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

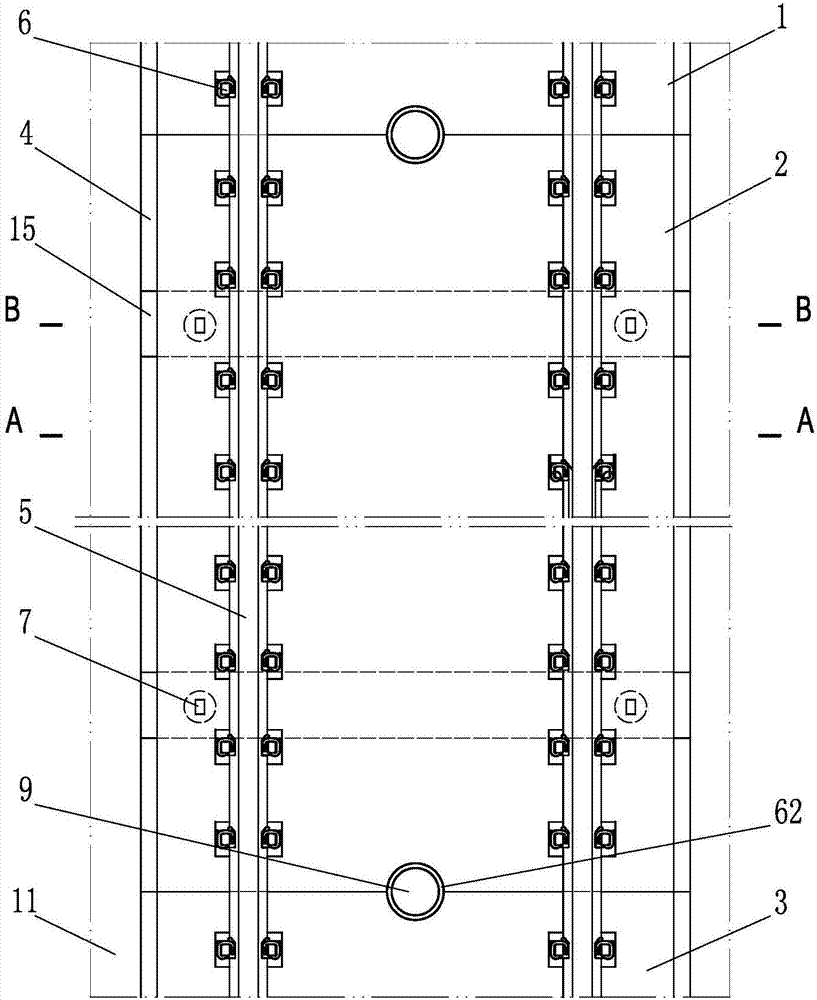

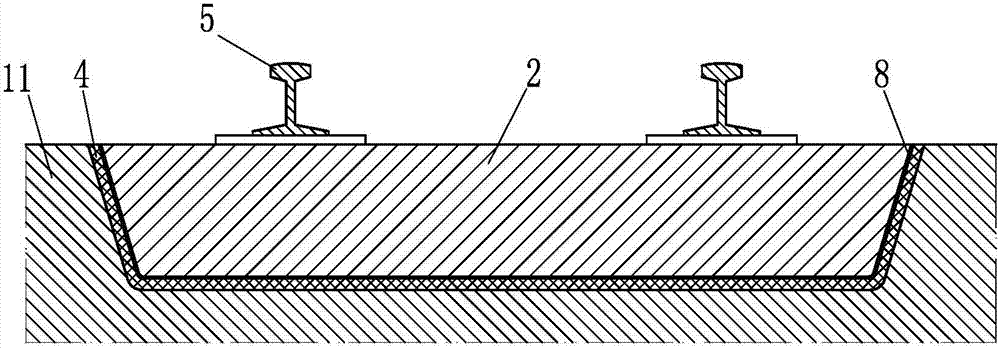

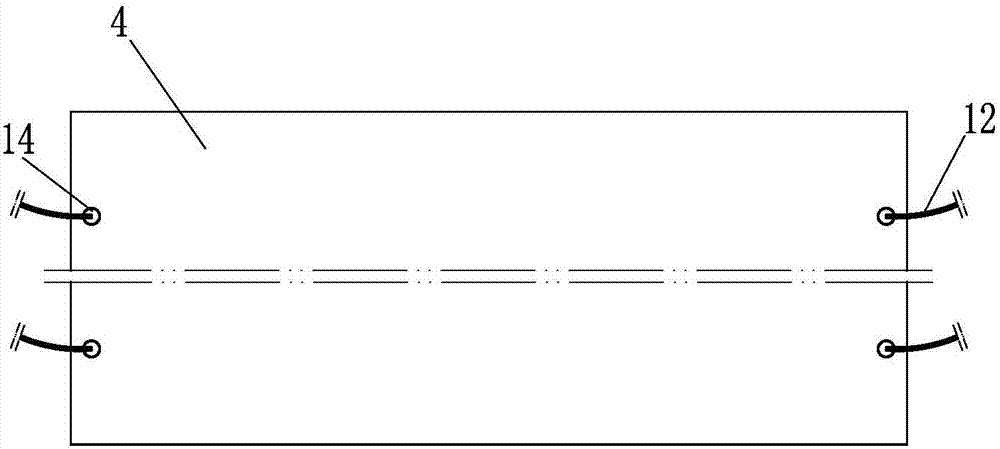

[0035] Such as figure 1 , figure 2 , image 3 and Figure 4 The easy-to-maintain elastic pad vibration damping track bed of the present invention includes elastic pad 4 and track plate. Due to the limited picture width, figure 1 The figure only shows the track slab 1 , the track slab 2 and the track slab 3 arranged successively in sequence, and each track slab is provided with a plate lifting structure 7 respectively. The structure of the easy-to-maintain elastic cushion damping track bed of the present invention is illustrated below by taking the track plate 2 as an example, as figure 1 and figure 2 As shown, the cross-section of the track plate 2 is an inverted trapezoid, and the contour of the foundation 11 matched with it corresponds to it. The elastic pad 4 is placed on the foundation 11, the track plate 2 is placed above the elastic pad 4, and between the track plate 2 and the elastic pad 4 An isolation layer 8 is also provided, and the isolation layer 8 is specif...

Embodiment 2

[0040] Such as Figure 5 , Figure 6 The difference between the easy-to-maintain elastic pad vibration-damping trackbed of the present invention and the first embodiment is that a limiting member 16 is set in the plate body lifting structure 7 set on the track plate. Still take the track plate 2 as an example, such as Figure 5 As shown in , the limiting member 16 is specifically a shear pin, the lower part of the shear pin is embedded in the foundation 11 , and the upper part of the shear pin is embedded in the plate lifting structure 7 . In this example, since the limit piece 16 is set in the plate body lifting structure 7, it can effectively prevent the relative movement between the track plate and the foundation during use, so basically there is no need to set a limit boss, and the track plate There is also no need to set a limit groove, so the structure of the track plate and the foundation is simpler, and the structure of the entire ballast bed is also simpler, which i...

Embodiment 3

[0043] Such as Figure 7 , Figure 8 The difference between the easy-to-maintain elastic pad vibration-reducing track bed of the present invention and Embodiment 1 is that the cross-sectional shape of the track plate is basin-shaped, and the structure of the easy-maintain elastic pad vibration-damping track bed of the present invention will be described below using the track plate 2 as an example. description, such as Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, the track plate 2 is provided with a plate body lifting structure, and the plate body lifting structure includes the lifting relief holes 50 respectively arranged at the two ends of the track plate 2 along the transverse direction of the rail, and the lower two sides of the lifting relief holes are respectively provided with Jacking groove 10 is arranged. In addition, the pad traction structure provided on the elastic pad 4 is specifically the traction rings 20 respectively provided at both ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com