A device for magnetic nanoparticle self-assembled photonic crystal fiber

A magnetic nanoparticle and photonic crystal fiber technology, applied in cladding fiber, optical waveguide light guide, microstructure fiber, etc., can solve the problems of complex production process, expensive special equipment and high cost, and achieve simple equipment and fast preparation speed. , the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The essential features and remarkable progress of the present invention will be clarified below through specific embodiments.

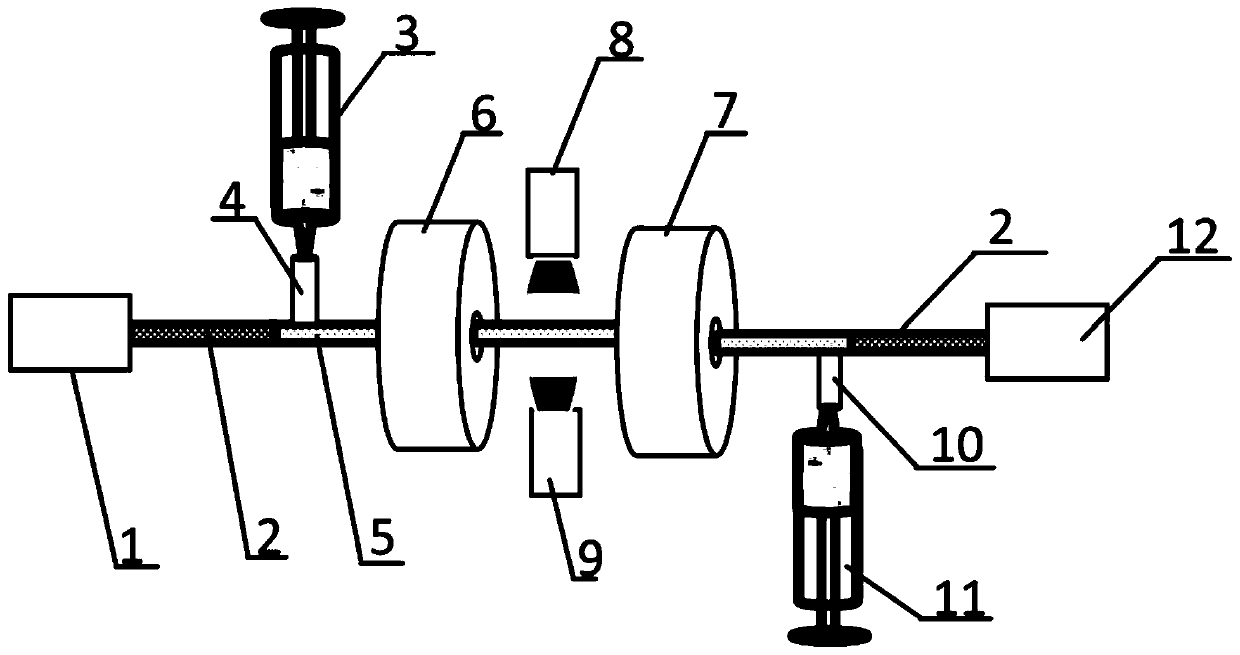

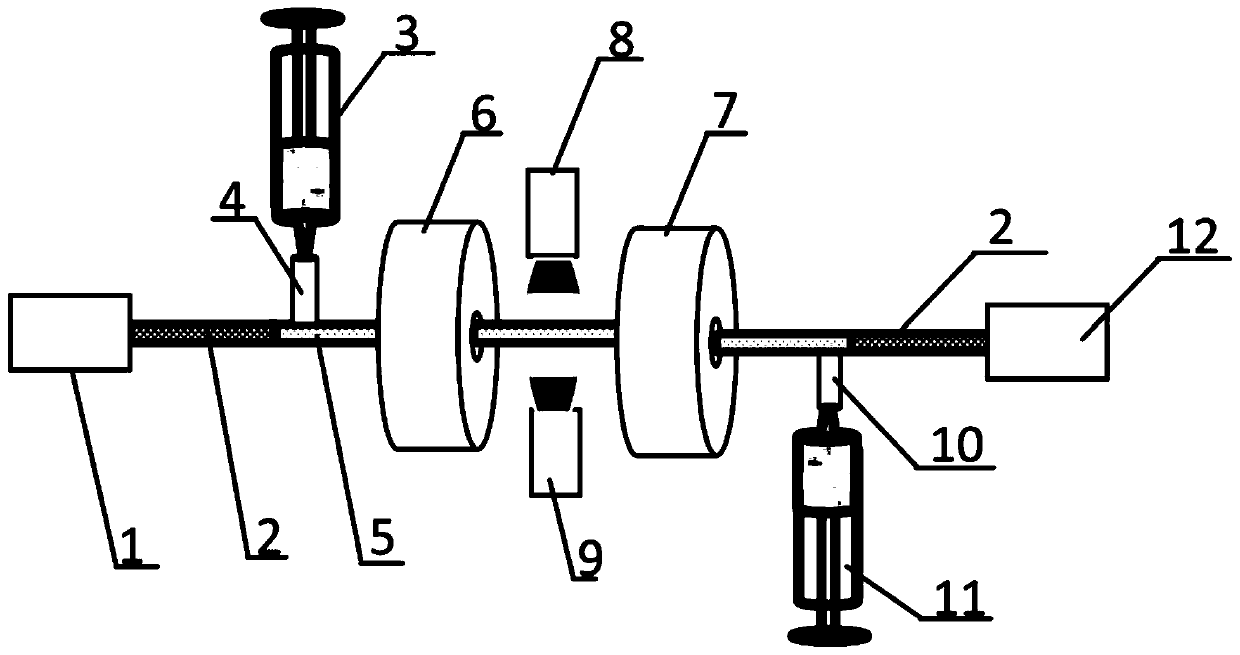

[0015] A device for magnetic nanoparticle self-assembly photonic crystal fiber. Compared with the traditional photonic crystal fiber manufacturing process, it uses the electromagnetic modulation characteristics of the magnetic nanoparticle structure to realize the preparation of photonic crystal fiber. The specific implementation method is to use a microbiological injector 3. Inject the UV glue liquid containing magnetic nanoparticles into the quartz capillary 5, generate a parallel high-frequency magnetic field with the help of the left high-voltage electromagnetic coil 6 and the right high-voltage electromagnetic coil 7, and make the magnetic nanoparticles complete periodic arrangement to build a photonic crystal structure. The micro-observer 8 monitors the formation process of the nanoparticle self-assembled photonic crystal structure in real...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com