Prefabricated concrete column component and connecting joint

A technology of prefabricated concrete and connecting nodes, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of difficult installation of components, affecting the node area, etc., and achieve the effects of simplifying construction, speeding up construction, and significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better illustrate the intention of the present invention, the content of the present invention will be further described below in conjunction with the accompanying drawings.

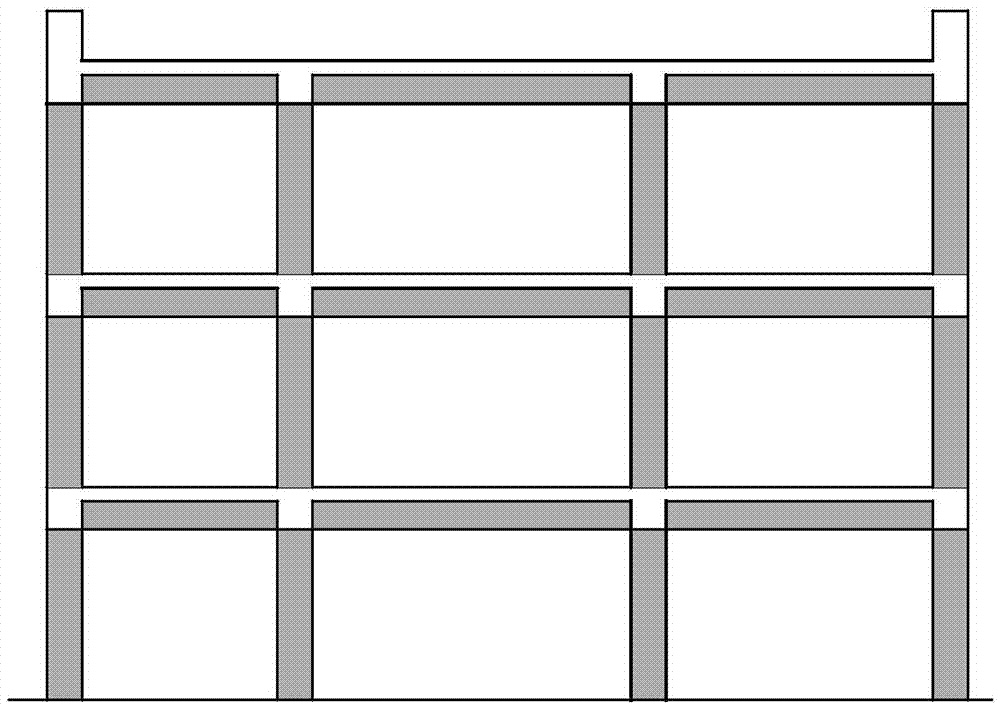

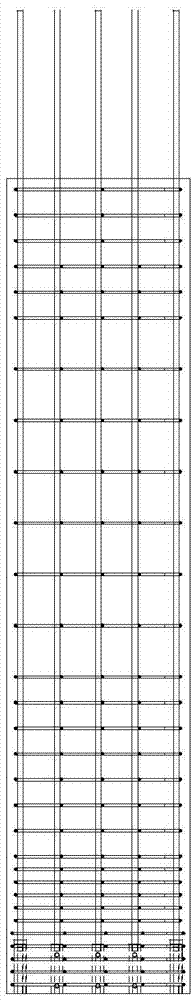

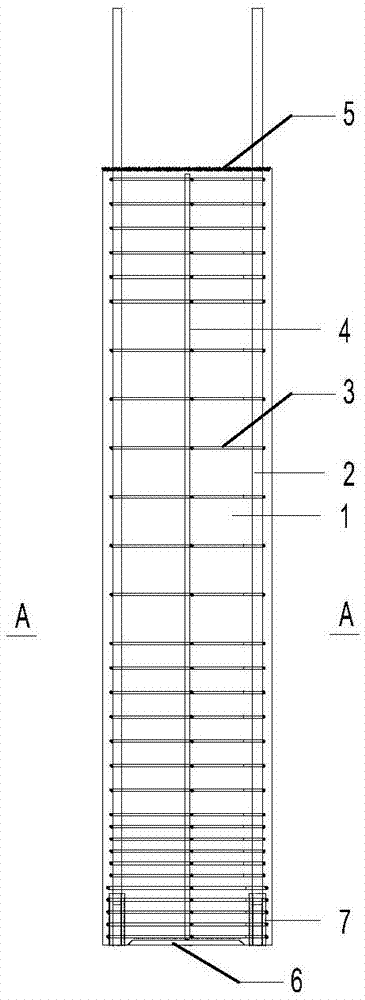

[0029] This embodiment relates to a prefabricated concrete column member, such as image 3 and Figure 4 as shown, image 3 It shows a prefabricated concrete column component, which is generally used in prefabricated concrete frame structures, and belongs to prefabricated components, which includes concrete 1 and steel skeleton, the steel skeleton is poured in concrete 1, and the steel skeleton includes longitudinal Stressed steel bars 2, transverse stirrups 3 and longitudinal structural steel bars 4, wherein the longitudinal stressed steel bars 2 and longitudinal structural steel bars 4 are attached to the inner side of the horizontal stirrups 3 and are bound and fixed with the stirrups 3, and the longitudinal stressed steel bars 2 Generally, large-diameter high-strength steel bars ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com