Combined spliced door frame

A door frame and column technology, which is applied in the field of assembled and spliced door frames, can solve the problems of large space occupation, transportation, handling troubles, welding troubles, etc., and achieve the effect of convenient assembly and combination, convenient transportation, and stable assembly structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

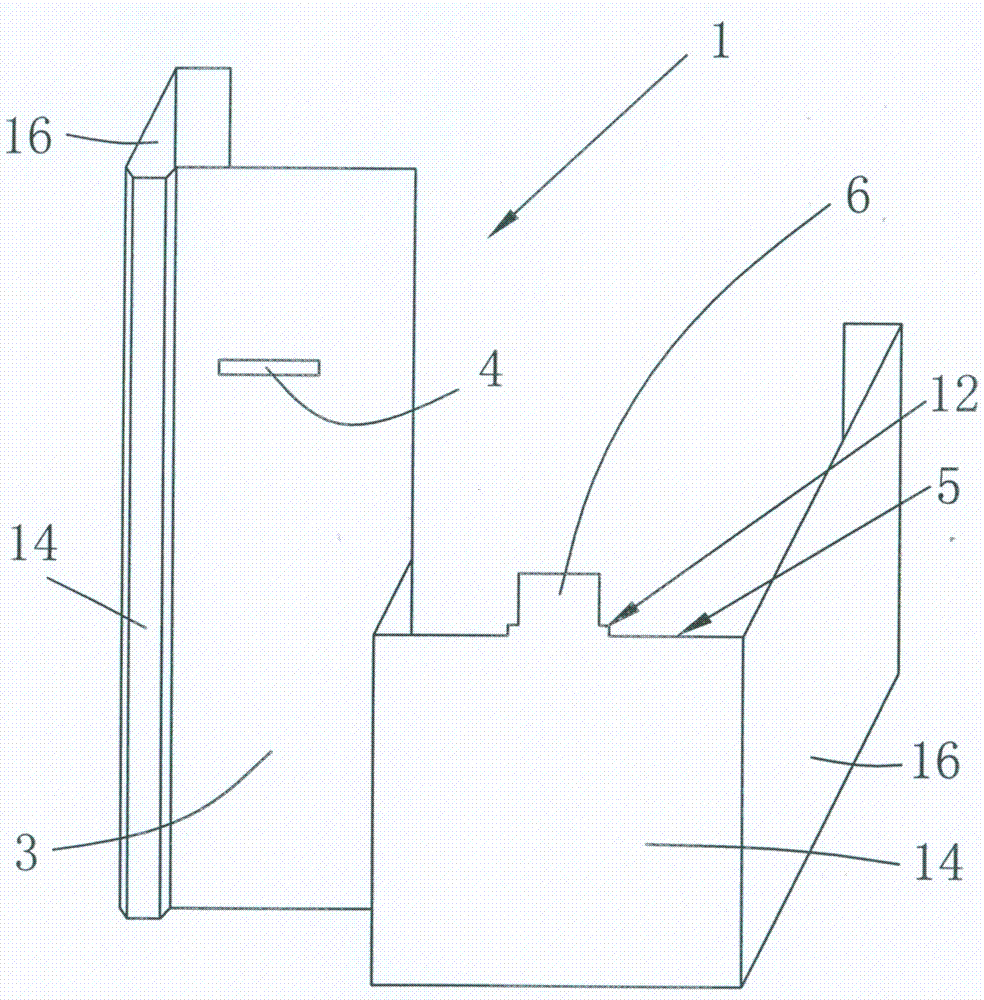

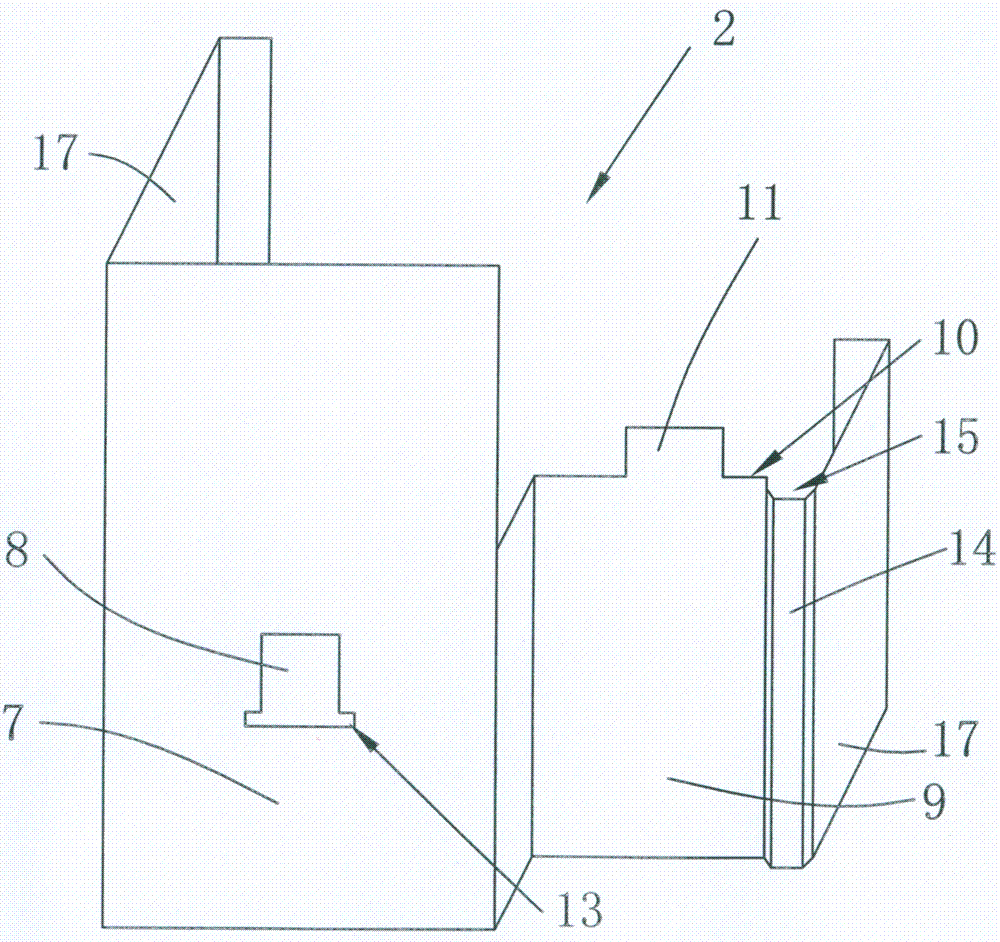

[0017] Referring to the accompanying drawings, the combined splicing door frame in this embodiment includes a column and a beam, and both the column and the beam have steps corresponding to the door. Both the upright column and the crossbeam are made of sheet metal as an integrated profile, and the metal sheet is made of iron or steel, or an alloy sheet can be used instead of the metal sheet.

[0018] The columns and beams are connected by splicing combination, that is, the columns and beams are split structures, which are connected by splicing and combination. Therefore, in the unassembled state, it is conducive to its handling, transportation, and storage, and more can be accommodated in the same space. The door frame effectively utilizes the space and reduces the cost.

[0019] During the splicing and combination, the splicing and combination is carried out through the column end 1 of the column and the beam end 2 of the beam. The low step 3 of the column end 1 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com