Semiconductor defrosting heater and refrigeration equipment

A frost heater and semiconductor technology, applied in the field of semiconductor defrosting heaters and a refrigeration equipment, can solve the problems of temperature rise, low heat utilization rate of heating pipes, affecting user experience, etc., and achieve the improvement of energy utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

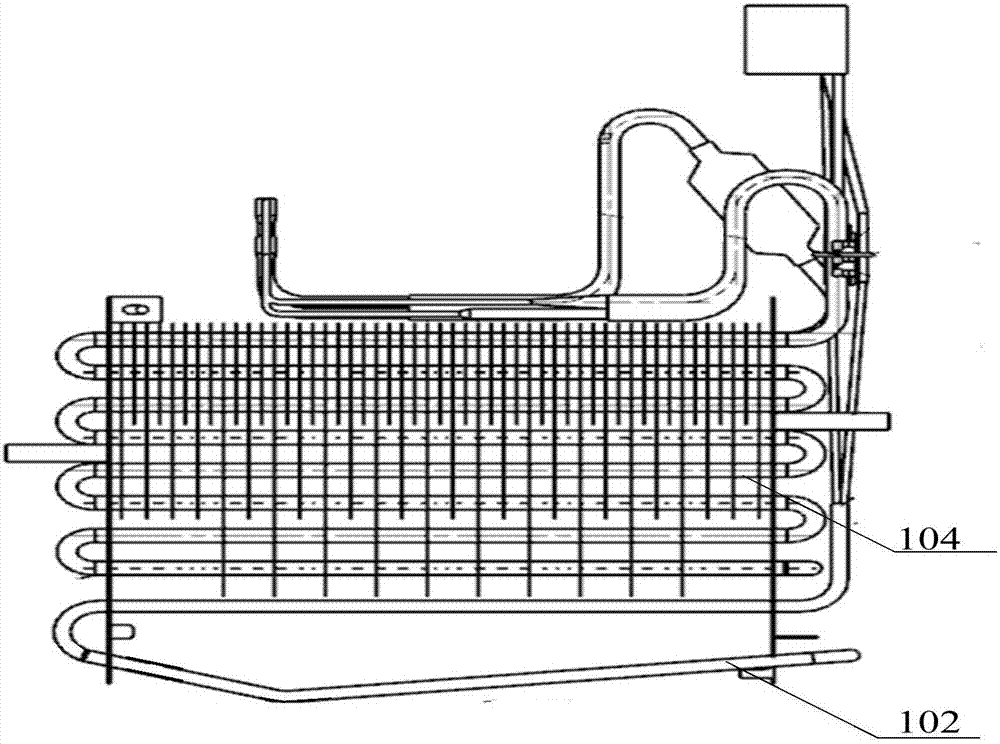

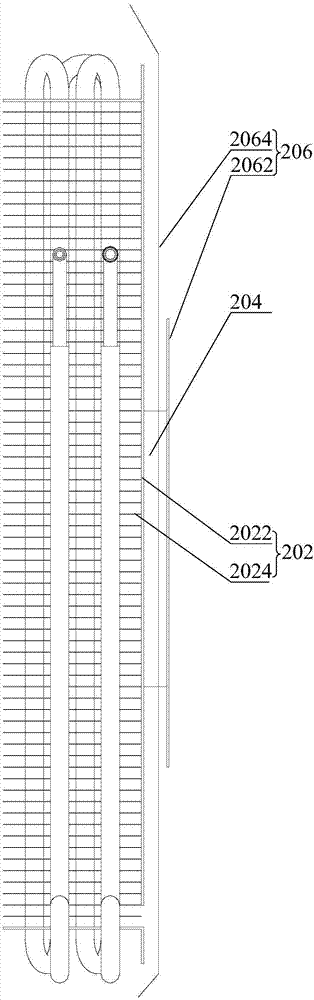

[0050] like figure 2 and Figure 4 As shown, in any of the above embodiments, preferably, the heat dissipation part 202 includes: a heat dissipation plate 2022, arranged side by side with the evaporator, and connected to the semiconductor cooling assembly 204; a plurality of heat dissipation fins 2024, along the air outlet direction of the evaporator One end of the cooling fin 2024 is connected to the cooling plate 2022, and the other end of the cooling fin 2024 is extended to be in contact with the evaporator.

[0051] In this embodiment, by contacting the heat dissipation plate 2022 with the semiconductor refrigeration assembly 204, the heat conduction efficiency of the semiconductor refrigeration assembly 204 to the outside is improved, and the heat dissipation area of the semiconductor refrigeration assembly 204 is increased. 2024, a plurality of cooling fins 2024 are in contact with the evaporator, and transfer the heat on the cooling plate 2022 to the evaporator thro...

Embodiment 2

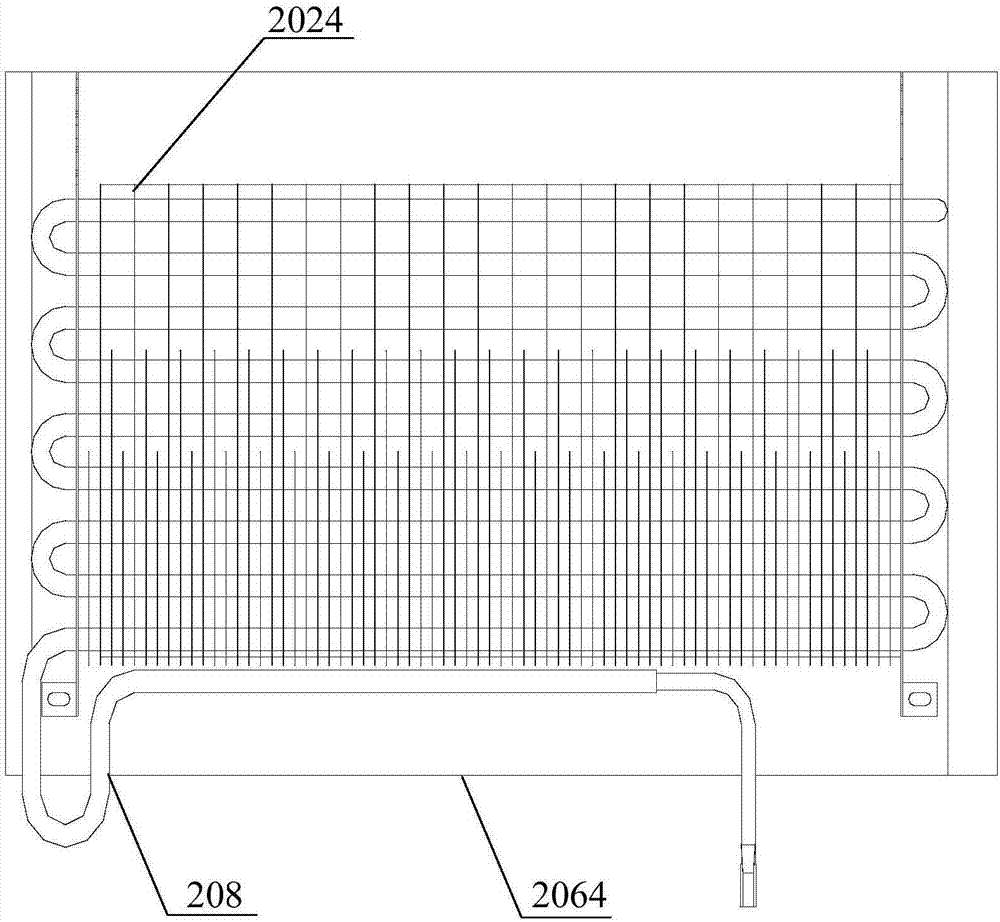

[0056] like image 3 As shown, in any of the above embodiments, preferably, the cooling fin 2024 is provided with a plurality of through holes in a direction perpendicular to the cooling plate 2022, and the cooling fin 2024 can be sleeved on the evaporator through the plurality of through holes.

[0057] In this embodiment, the radiating fins 2024 are evaporator fins on the evaporator. By providing a plurality of through holes on the radiating fins 2024, the evaporating tubes 208 of the evaporator can be distributed in various ways on the plurality of radiating fins 2024. Ways, for example, the evaporating tubes 208 can be distributed in multiple rows and columns on multiple cooling fins 2024 to improve space utilization and heat utilization of the cooling fins 2024 .

[0058] Preferably, the heat sink 2024 is sleeved on the evaporator through a plurality of through holes, periodically heating and defrosting the evaporator, and usually used as an evaporating fin of the evapora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com