A microwave frequency measurement method and device based on an optical frequency comb

A technology of microwave frequency measurement and optical frequency comb, which is applied in the direction of frequency measurement devices, measurement devices, and measurement of electrical variables, can solve the problems of poor real-time performance, measurement accuracy only in the order of GHz, and uneven measurement accuracy, and achieve measurement resolution The effect of high rate and small frequency measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

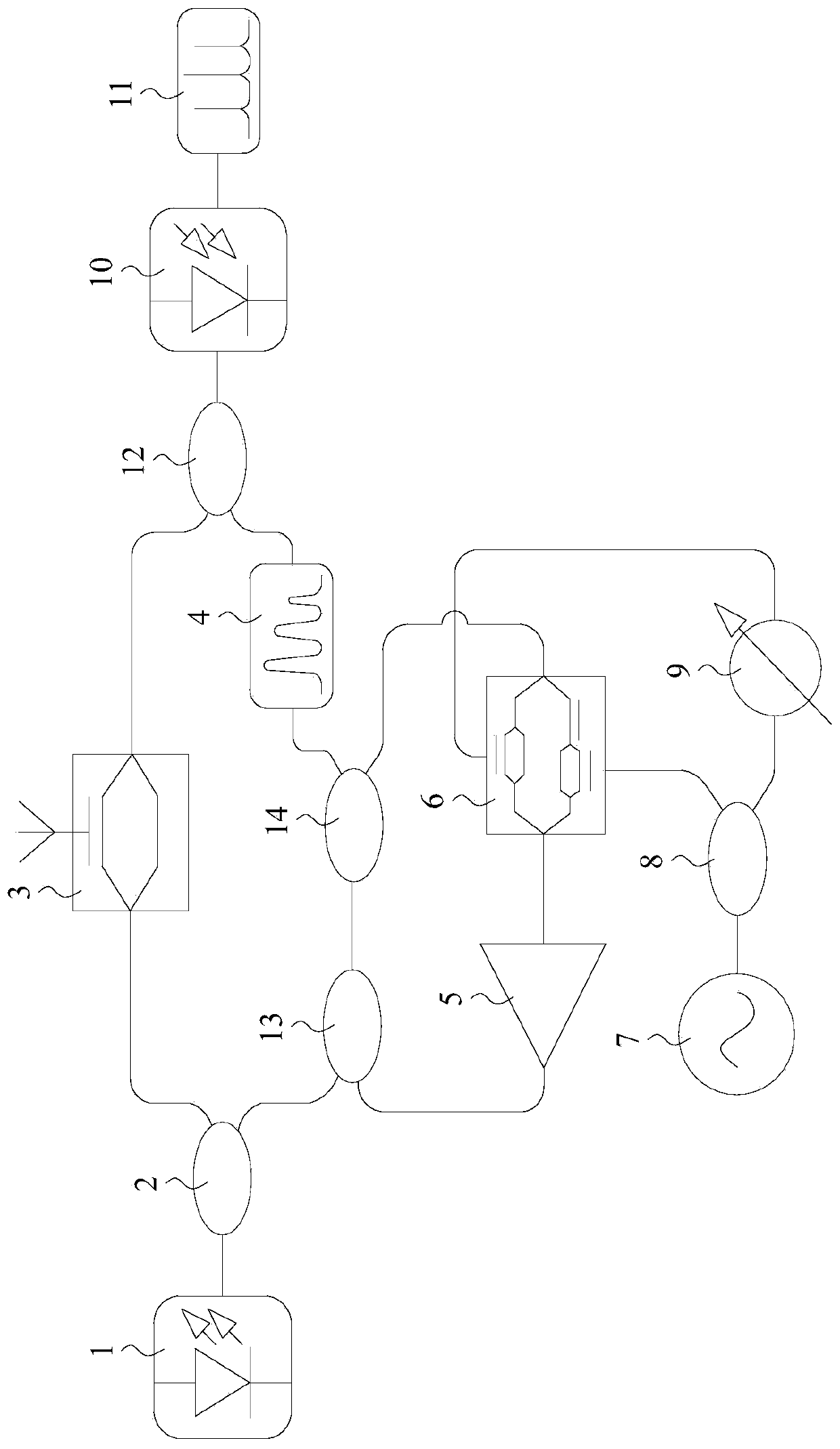

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

[0032] Such as figure 1 As shown, a method for measuring microwave frequency based on an optical frequency comb involved in this embodiment, the steps are as follows:

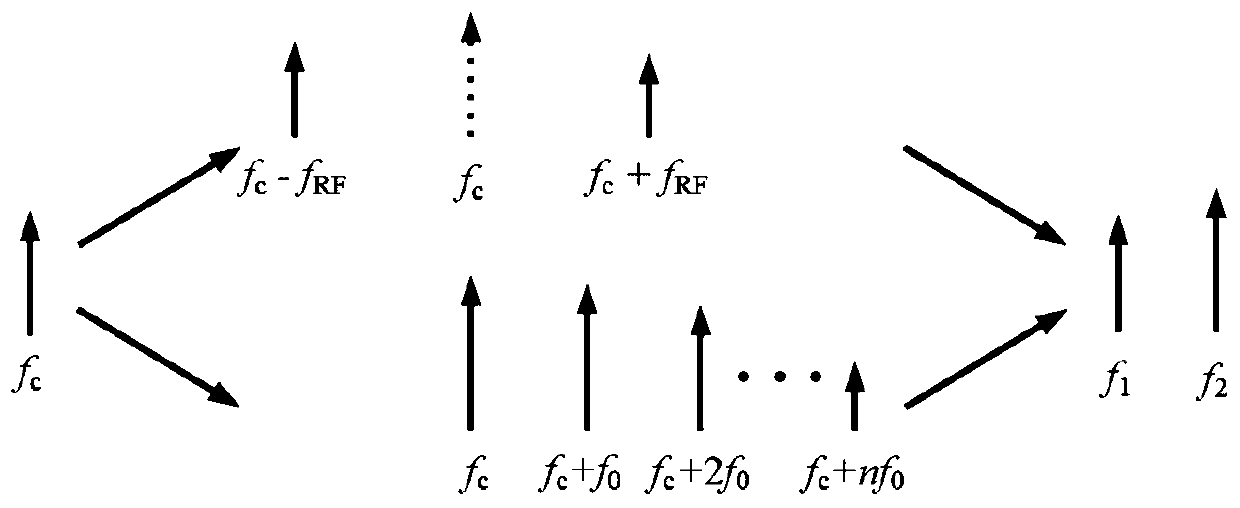

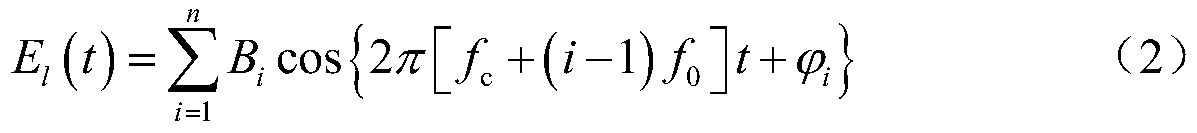

[0033] Step 1. The frequency f is generated by the laser c The laser signal is divided into two parts, one of which is composed of frequency f RF Carrier-suppressed double-sideband modulation is performed on the unknown RF signal, and the modulated signal light field is approximately expressed as:

[0034] E. u (t)=E 0 sin[βcos(2πf RF t)]≈A +1 cos[2π(f c + f RF )t]+A -1 cos[2π(f c -f RF )t] (1)

[0035] where A ±1 =J 1 (β) is the amplitude of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com