Oil pipe inner wall cleaning machine for oil development

A technology for oil extraction and inner wall cleaning, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc. It can solve the problems of low work efficiency, stuck drill bits, and cannot be washed down by water, etc., and achieves good cleaning effect, Increases usage rate and reduces damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with accompanying drawing.

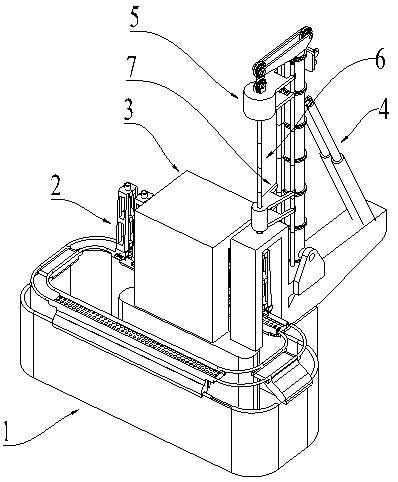

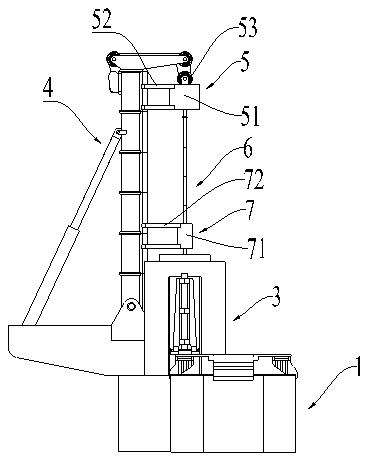

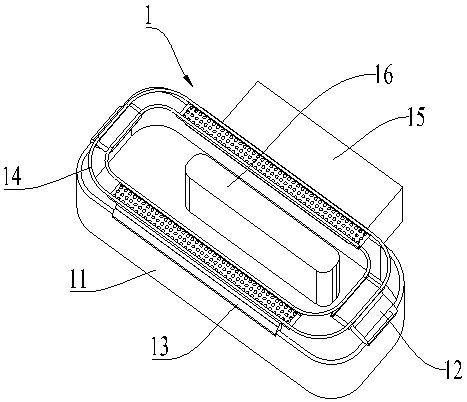

[0058] Such as figure 1 with figure 2 As shown, the embodiment of the present invention discloses a oil pipe inner wall cleaning machine for oil development, including a collection pool device 1, a oil pipe clamp device 2, a heating device 3, a cleaning platform device 4, a power head 5 and a cleaning rod device 6, The oil pipe clamp device 2 is arranged on the collection tank device 1 and can slide relative to the collection tank device 1, the heating device 3 is arranged on the collection tank device 1 to heat the oil pipe clamp device 2, and the cleaning platform device 4 is connected with the collection tank device 1. The pool device 1 is correspondingly arranged, the power head 5 and the cleaning rod device 6 are arranged on the cleaning platform device 4, the power head 5 is connected with the cleaning rod device 6 and can drive the cleaning rod device 6 to rotate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com