Frequency conversion helical-lobe compressor rotor structure and frequency conversion helical-lobe compressor

A technology of screw compressor and rotor structure, applied in the field of compressors, can solve the problems of reducing compressor efficiency, increasing compressor power consumption, increasing bearing oil churning power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

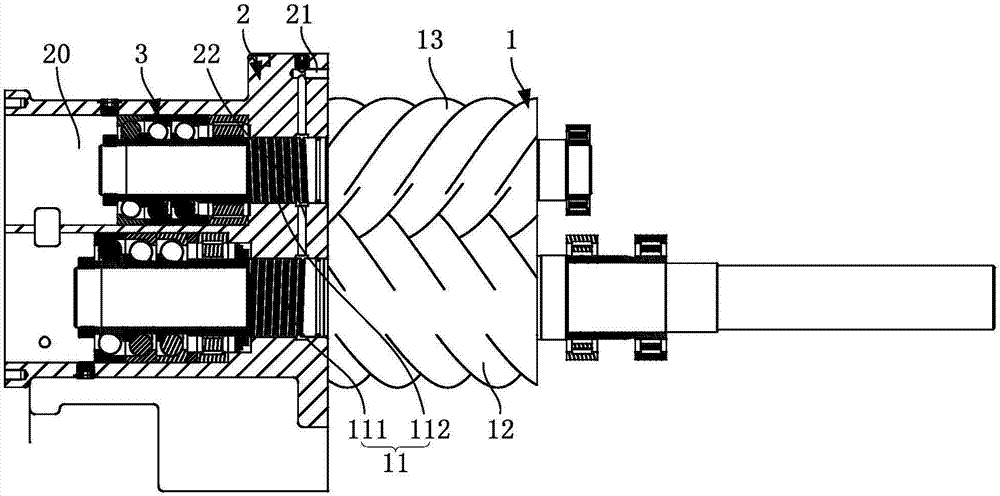

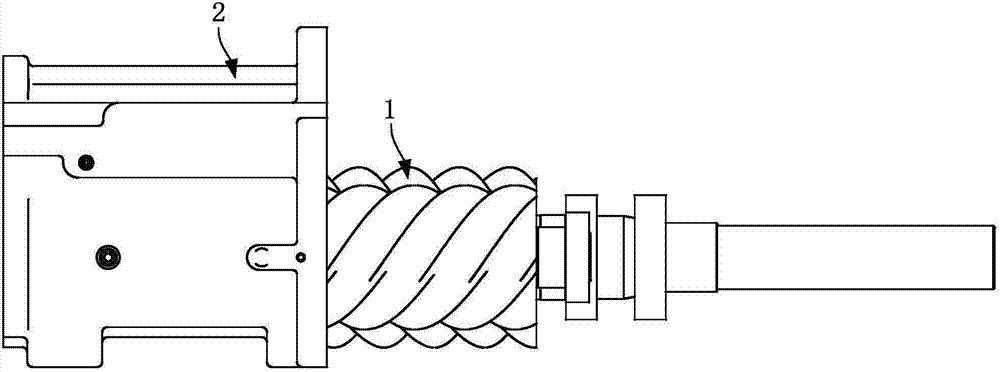

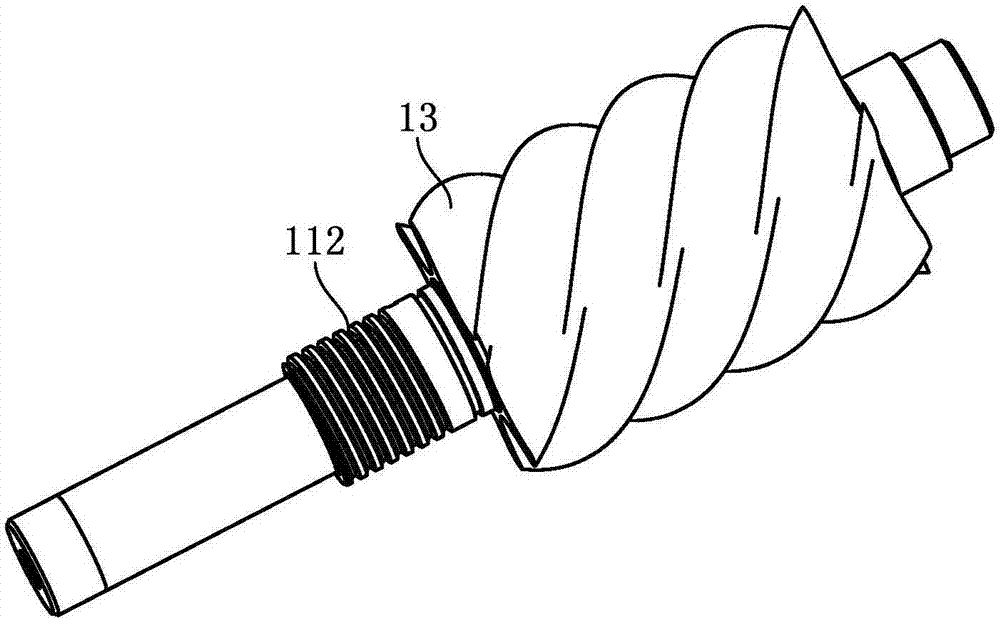

[0031] Combine below Figure 1 ~ Figure 3 The technical solution provided by the present invention is described in more detail.

[0032] see figure 1 , the embodiment of the present invention provides a variable frequency screw compressor rotor structure, including a rotor part 1, a support seat 2 and a support part 3, the support part 3 is arranged in the cavity 20 of the support seat 2, and the journal end of the rotor part 1 Supported by the support part 3, the meshing part of the rotor part 1 is located outside the support seat 2; wherein, the journal of the rotor part 1 is provided with a first oil passage 11, the support seat 2 is provided with a second oil passage 21, and the first oil passage 11 It is in periodic communication with the second oil passage 21 , wherein the external oil can flow to the support part 3 in the cavity 20 via the second oil passage 21 and the first oil passage 11 in sequence.

[0033] The high-pressure lubricating oil in the oil cylinder flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com