Fire cover structure of concealed fire leading groove

A hidden, fire cover technology, applied in the direction of gas fuel burner, combustion method, combustion type, etc., can solve the problem that the ignition groove is easily blocked by oil stains and foreign objects, affects the ignition effect and appearance, and the groove is deformed or broken. , to achieve a wide range of ignition, improve performance and safety performance, prevent deflagration or explosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

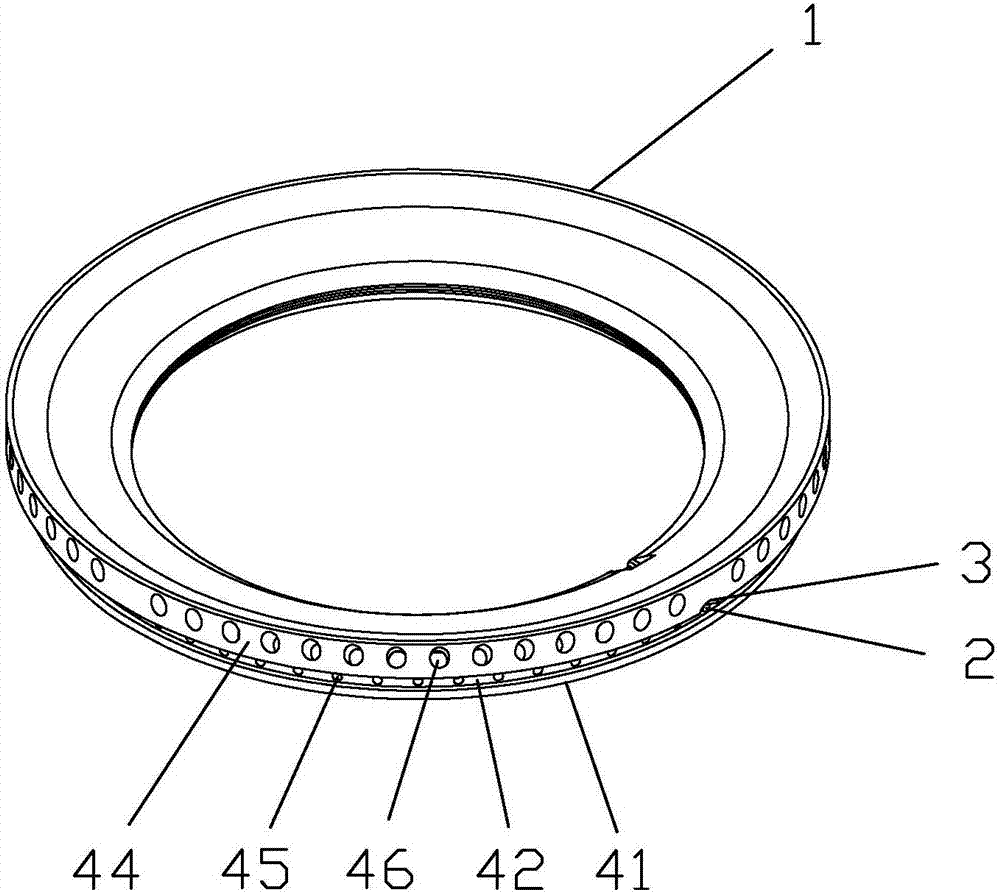

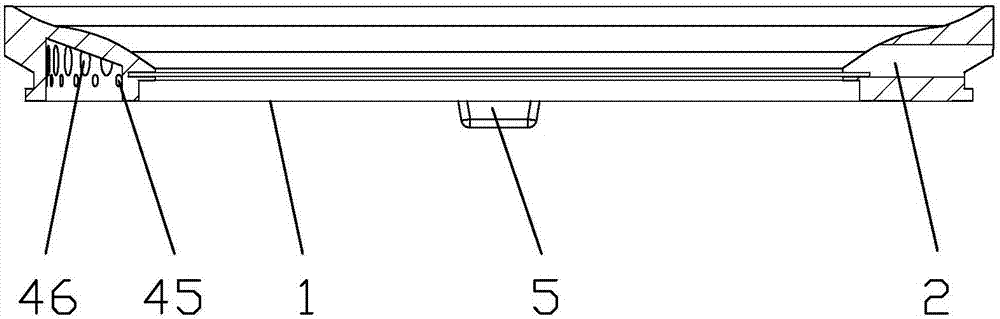

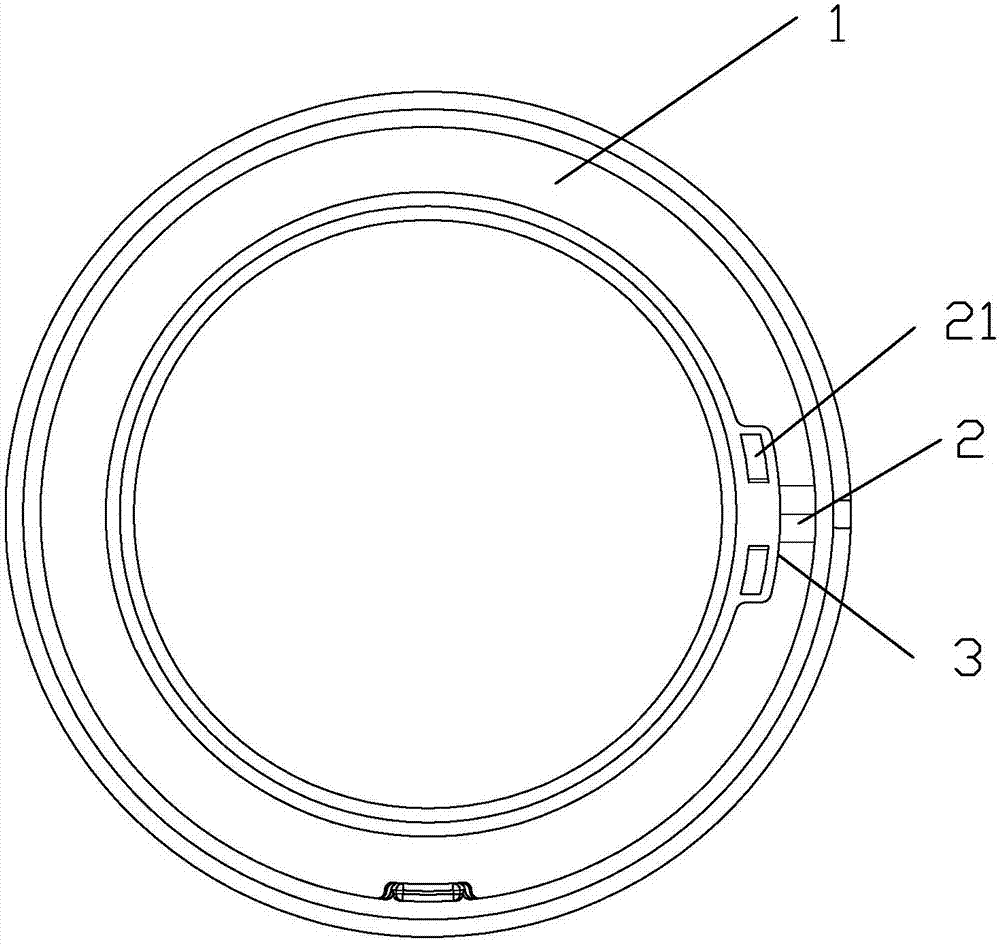

[0020] like Figure 1-4 As shown, it is a fire cover structure of a hidden fire trough of the present invention, including a fire cover body 1 and a fire trough 2, an annular gas cavity is arranged in the fire cover body 1, and the fire trough 2 is located at the bottom of the fire cover body 1. Inside, and the fire starting groove 2 radially penetrates the fire cover body 1, and the inner ring flame passes the flame to the first combustion hole 45 and the second combustion hole 46 of the fire cover through the fire ignition groove 2 in the fire cover body 1, forming combustion, and the The ignition groove 2 is arranged in the inside of the fire lid body 1, which neither destroys the appearance of the fire lid, but also prevents soup, vegetable leaves and other foreign matter from blocking the ignition groove 2, effectively prevents deflagration or explosion, improves the performance of the fire lid, and Avoid flame splashing and improve safety performance. The inner ring wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com