Friction-lasso composite energy-dissipative fabricated steel beam-column system capable of multi-stage vibration reduction

A prefabricated and energy-consuming technology, which is applied in the direction of building types, protected buildings/shelters, buildings, etc., can solve the problems of building aesthetics in building space, insufficient energy consumption, and large space occupation, etc., to achieve Short construction period, improved energy consumption capacity and safety, and improved energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

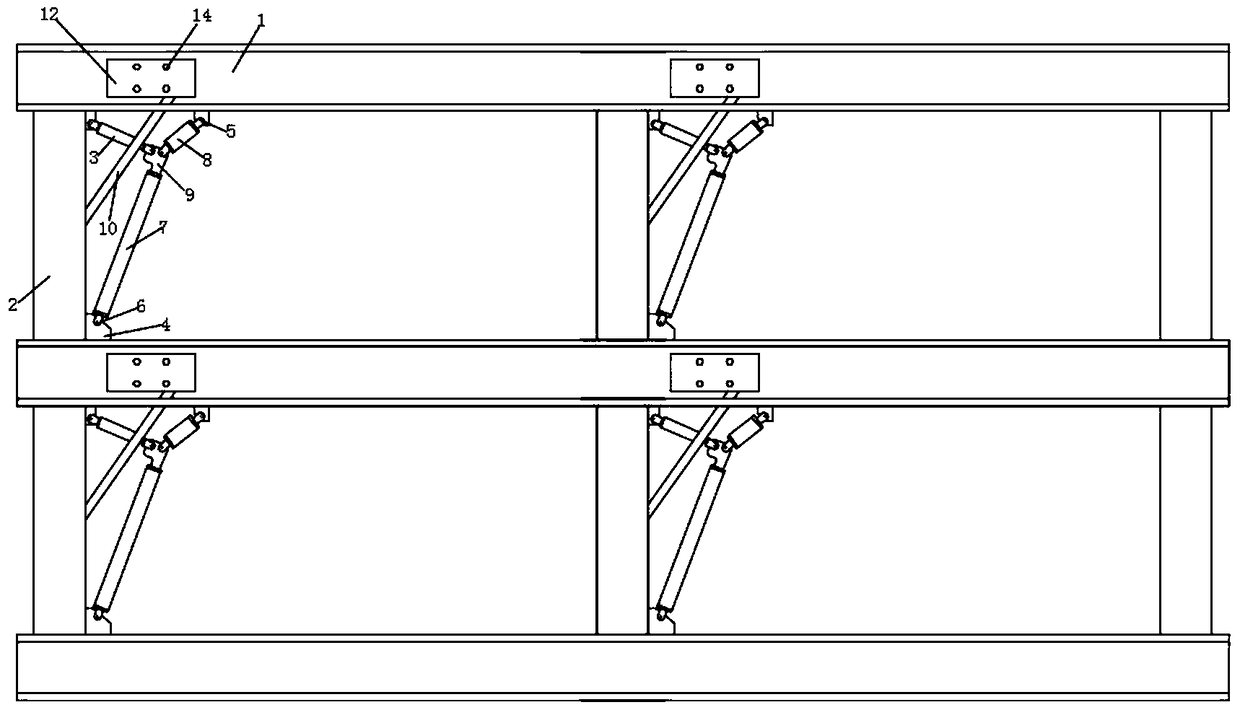

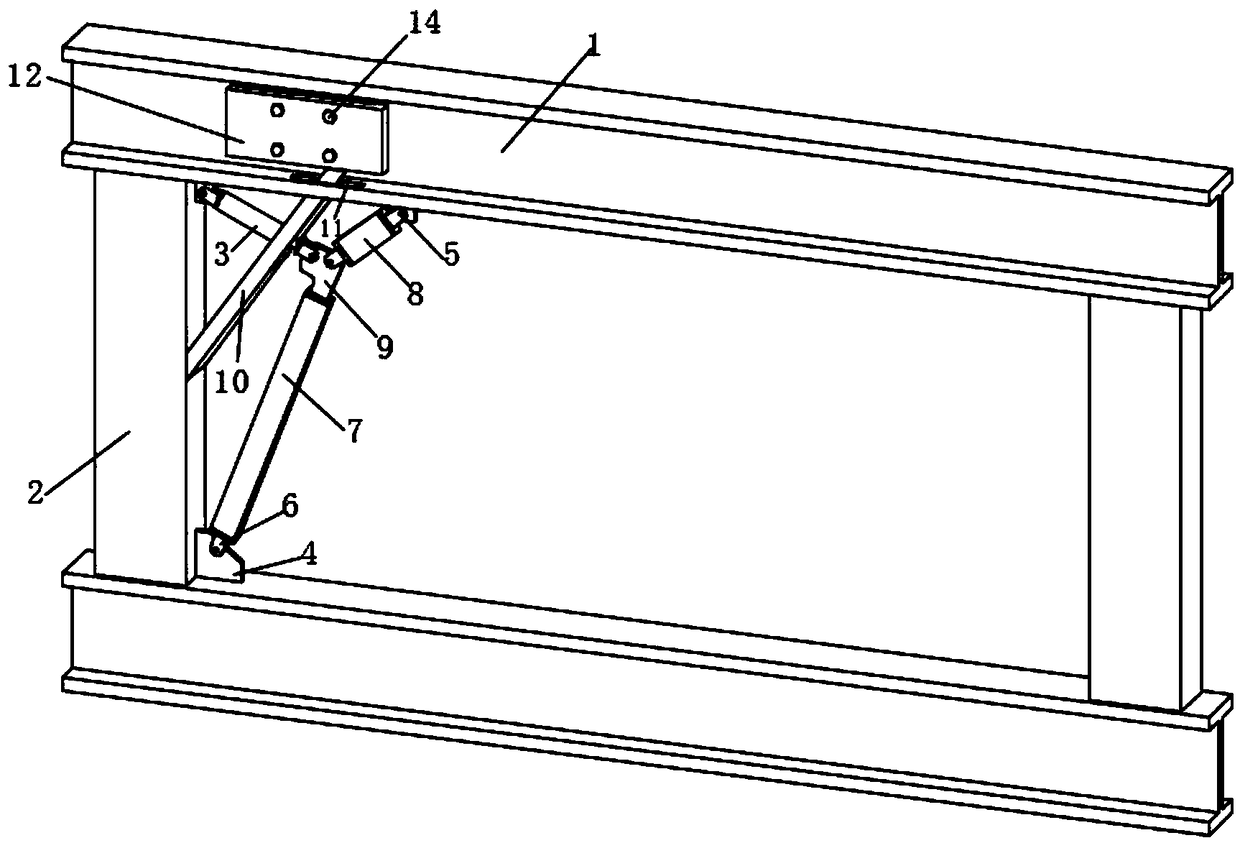

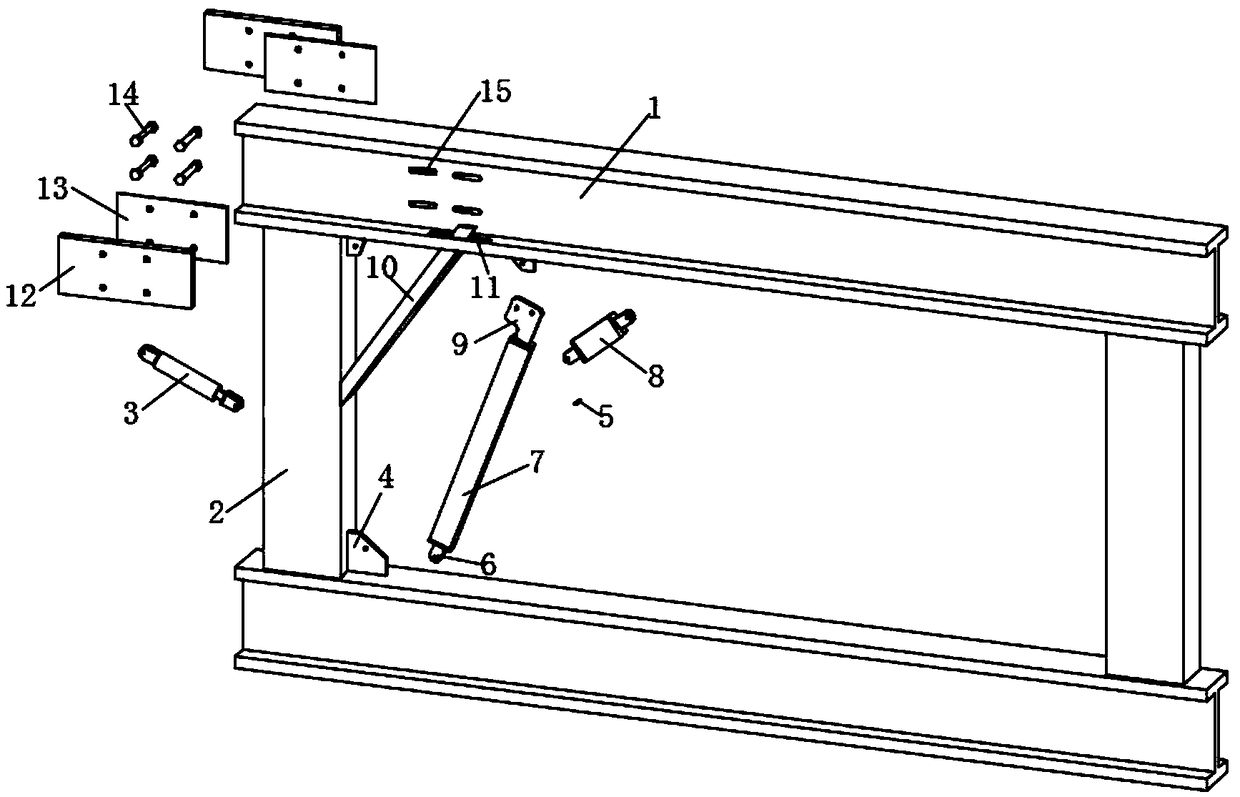

[0037] For a 20-story steel frame structure located in an 8-degree fortification intensity zone, a friction-lasso composite energy-dissipating fabricated steel beam-column system capable of multi-stage vibration reduction is used to achieve shock absorption for its seismic requirements. Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0038] as attached figure 1 Shown is a design example of the friction-lasso composite energy-dissipating assembled steel beam-column system of the present invention, which includes: assembled steel beams, assembled steel columns, dampers, gusset plates, pins , ear plate, lower connecting rod, upper connecting rod, connecting plate, fork-type brace, flange long hole, friction plate, friction plate, bolt, web long hole. The above-mentioned components are prefabricated in the factory, and two pairs of ear plates are welded at both ends of the damper and the upper link, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com