Large partition glass corridor curtain wall connection structure

A technology of connecting structure and large grid, applied in the direction of walls, building components, building structures, etc., can solve the problem that it cannot withstand the self-weight of large grid glass plates and other external forces, and it is difficult to meet the design effect and impact of the open facade curtain wall of buildings. The safety and sealing of the glass curtain wall can be beneficial to the construction and installation, meet the appearance effect, and improve the construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

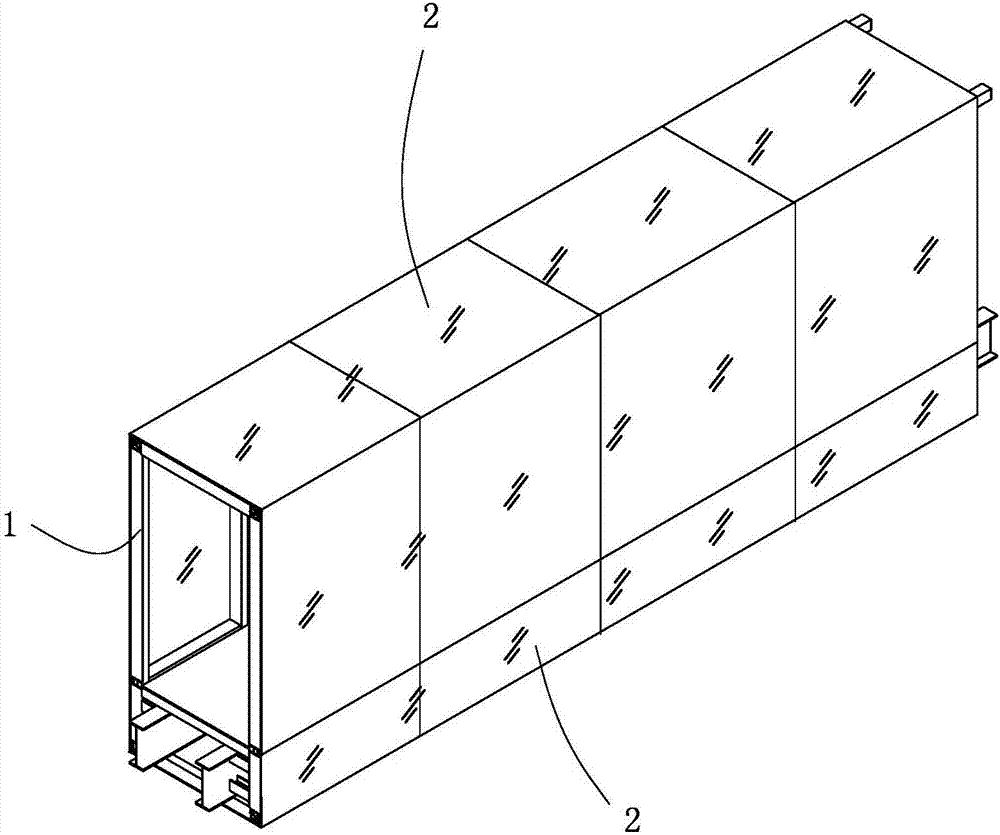

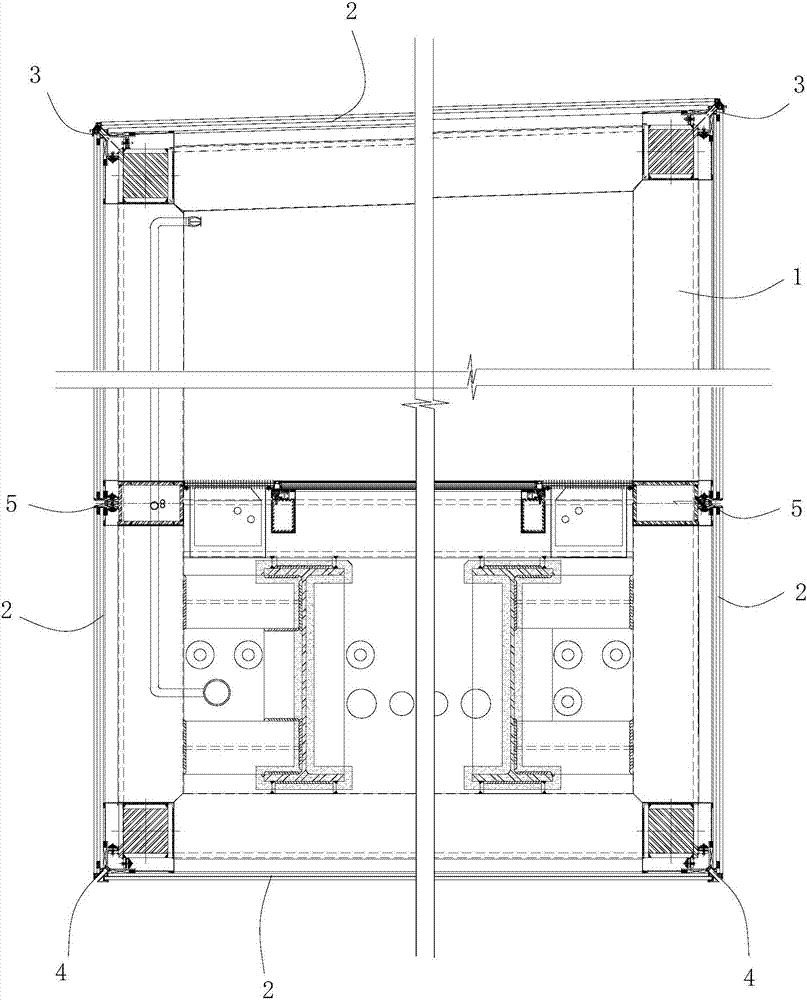

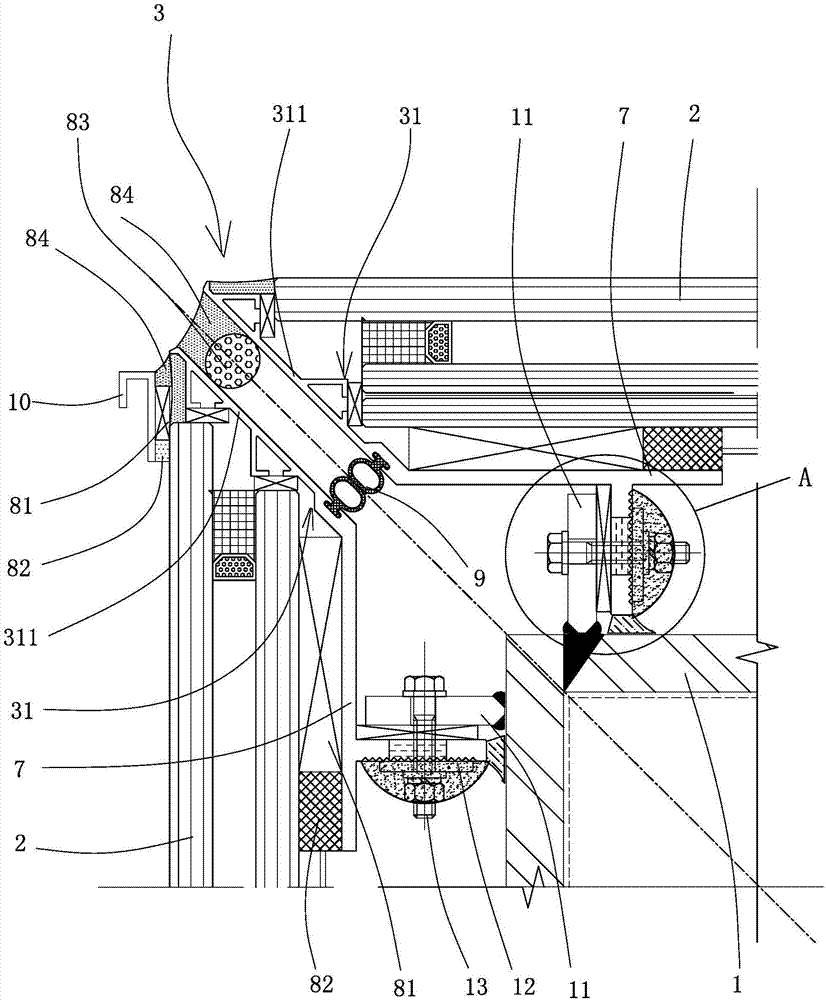

[0031] In the present invention, the curtain wall connection structure of the large compartment glass gallery, the glass gallery includes at least one glass gallery unit U spliced with each other, and each of the glass gallery units U includes a gallery skeleton 1 and is fixed on the The double-layer glass plate 2 outside the corridor skeleton 1; the corridor skeleton 1 is made by conventional prior art. The sub-frame assembly includes an upper corner sub-frame assembly 3, a lower corner sub-frame assembly 4, a side sub-frame assembly 5, and a bottom sub-frame assembly 6; Figure 1-10 The present invention will be described in detail.

[0032] Such as figure 1 As shown, in this embodiment, the connecting structure of the curtain wall of the large partitioned glass corridor is a long corridor formed by splicing left and right of two or more glass corridor units U.

[0033] Such as figure 2 , 3As shown, the present invention uses multiple sets of upper corner sub-frame as...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap